/MAT/LAW77

Block Format Keyword This open cell foam material law is a generalization of LAW70. It accounts for a non-viscous compressible ideal gas flow inside of the foam and its interaction with the foam structure.

ALE simulation of the gas flow and Lagrangian simulation of the foam deformation is performed on the same elements system. Interaction between the gas flow and the structure is through Darcy law and direct application of the gas pressure to the structure.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW77/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E0 | Emax | FP0 | |||||||

| Fcut | Fsmooth | NL | NuL | Iflag | Shape | Hys | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDL | FscaleL | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDuL | FscaleuL | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| P0 | R | ||||||||

| Pext | Iclos | Inc_gas | |||||||

| K | |||||||||

| fct_IDK | fct_IDR | ||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| mat_title | Material title (Character, maximum 100 characters) |

|

| Initial density (Real) |

||

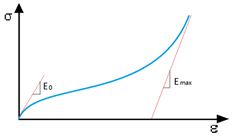

| E0 | Initial Young's

modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| Emax | Maximum Young's modulus. (Real)

|

|

| Reference strain value for the maximum

Young's modulus usage. Default = 1 (Real) |

||

| FP0 | Initial foam pressure. Default = 0 (Real) |

|

| Fcut | Cutoff frequency for strain rate

filtering. Default = 1020 (Real) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| NL | Number of loading functions. Default = 0 (Integer) |

|

| NuL | Number of unloading functions. Default = 0 (Integer) |

|

| Iflag | Unloading response control flag.

(Integer) |

|

| Shape | Shape factor describes the "convexity"

of the unloading curve.

Default = 1.0 (Real) |

|

| Hys | Hysteresis unloading factor. Default = 1.0 (Real) |

|

| fct_IDL | Load function

identifier. (Integer) |

|

| Strain rate for load

function. (Real) |

||

| FscaleL | Load function scale factor. Default = 1.0 (Real) |

|

| fct_IDuL | Unload function

identifier. (Integer) |

|

| Strain rate for unload

function. (Real) |

||

| FscaleuL | Unload function scale factor. Default = 1.0 (Real) |

|

| Air density. Default = 0 (Real) |

||

| P0 | Initial pressure. Default = 0 (Real) |

|

| Gamma constant for the gas. Default (Real) |

||

| External gas density. Default is (Real) |

||

| Pext | External pressure. Default = P0 (Real) |

|

| Inc_gas | Reverse flow flag.

(Integer) |

|

| R | Initial porosity fraction of element

volume filled with the gas. (0 < R < 1)

(Real) |

|

| Linear parameter for generalized Darcy

Law. Default = 0 (Real) |

||

| Quadratic parameter for generalized

Darcy Law. Default = 0 (Real) |

||

| Transient parameter for generalized

Darcy Law. Default = 0 (Real) |

||

| K | Initial foam permeability

modulus. Default = 0 (Real) |

|

| Iclos | Open/close the free surface of the solid

block flag (surface not connected to any solid element).

(Integer) |

|

| fct_IDK | Permeability scale factor function

(scale versus relative foam density).

(Integer) |

|

| fct_IDR | Porosity scale factor function (scale

versus relative foam density).

(Integer) |

Example (Cell Foam)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW77/1/1

Open cell foam

# RHO_I

4.5E-8

# E0 NU EMAX EPS_max FP0

.1 0 5 .99

# FCUT FSMOOTH NLOAD NUNLOAD IFLAG SHAPE HYS

.1 1 1 0 3 2 1E-20

# F_ID_ID SLOAD FSCALELOAD

1 0 .001

# RHO_AIR P0 GAMMA R

1.2E-9 1.0E-4 1.4 1.0

# RHO_EXT P_EXT ICLOSE INC_GAS

1.2E-9 1.0E-4 2 0

# ALPHA BETA T K

1 5 0 1e07

# F_ID_K F_ID_R

2 3

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/1

LoadCurve

# X Y

-.8 -.11

-.7 -.10

-.4 -.05

-.2 -.02

0 0

.2 .004

.4 .006

.6 .01

.7 .020

.8 .050

.99 134

/FUNCT/2

Funct_2

# X Y

0.0 0.2

0.555 0.2

0.909 1.0

1.0 1.0

/FUNCT/3

Funct_3

# X Y

0.0 0.25

0.555 0.25

0.909 0.55

1.0 0.55

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/ENDComments

- This material law can be used only with

solid non-degenerated hexa elements. This material is available only for the following

parameters in the solid property:

- Isolid = 1 (Belytschko)

- Ismstr = 1 (small strain)

- Iframe = 1 (non co-rotational)

- For stresses above the last load function, the behavior is extrapolated by using the last two load functions. In order to avoid huge stress values, it is recommended to repeat the last load function.

- Non-viscous flow of a perfect gas using the ALE approach is considered.

- When reaches , in one integration point, the deviatoric stress of the corresponding integral point is permanently set to 0; however, the solid element is not deleted.

- For coupling between the foam and the gas,

use the modified Darcy's law (Dupuit-Forchiemer):

(7) Where,- Velocity of the fluid

- Fluid pressure

- Permeability modulus

- In order to save the structural stress,

strain and gas flow data, the following options have to be used in Engine

file:

/STATE/BRICK/STRAIN/FULL

/STATE/BRICK/STRESS/FULL

/STATE/BRICK/AUX/FULL

- Pre-stress of the foam and initial state of the air inside of the foam can be defined from pre-stress simulation and read into the model with /INIBRI/STRS_F, /INIBRI/STRA_F and /INIBRI/AUX cards.

- The following user variables are available

to output gas flow data into animation (/ANIM/BRICK/TENS) or time history (/TH/BRIC) file:

- USR1: gas density

- USR20: gas pressure

- USR21: R value

- USR22: K value

- Gas velocity vector field can be output in animation with /ANIM/VECT/GVEL.