Tutorial 7: Transient Flow Analysis using Feed Forward Controller Model

Purpose/Objective:

This exercise will show the user how to create a Feed Forward Controller that will adjust a valve opening position based on the valve upstream pressure. The user will learn how to:

- Create a Feed Forward Controller

- Setup a transient run

- Check the model

- Run the model

- Post-process the model

- Elements used: Conventional Orifice, Standard Tube, Ball Valve, FFWD Controller, Generic Fixed Volume Accumulator.

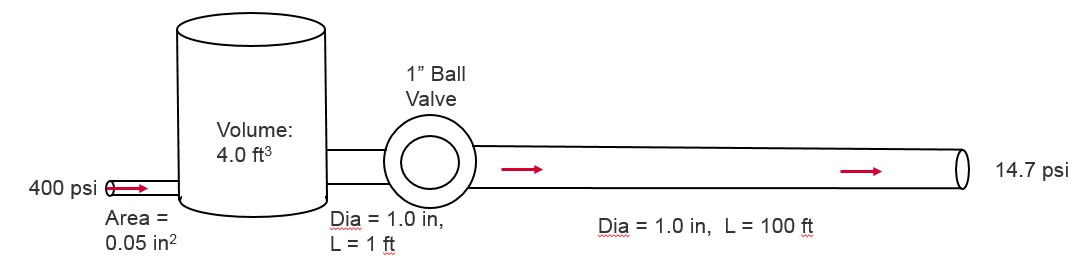

Step 1: Create plan

- The goal of this exercise is to determine time it takes a volume to pressurize up to

400 psi from a small leak and then how long it takes to depressurize the volume

after a valve is opened by a feed forward controller.

- Volume initial pressure = 14.7 psi

- Fluid = air; Use compressible gas elements

Figure 1.01: Model Plan

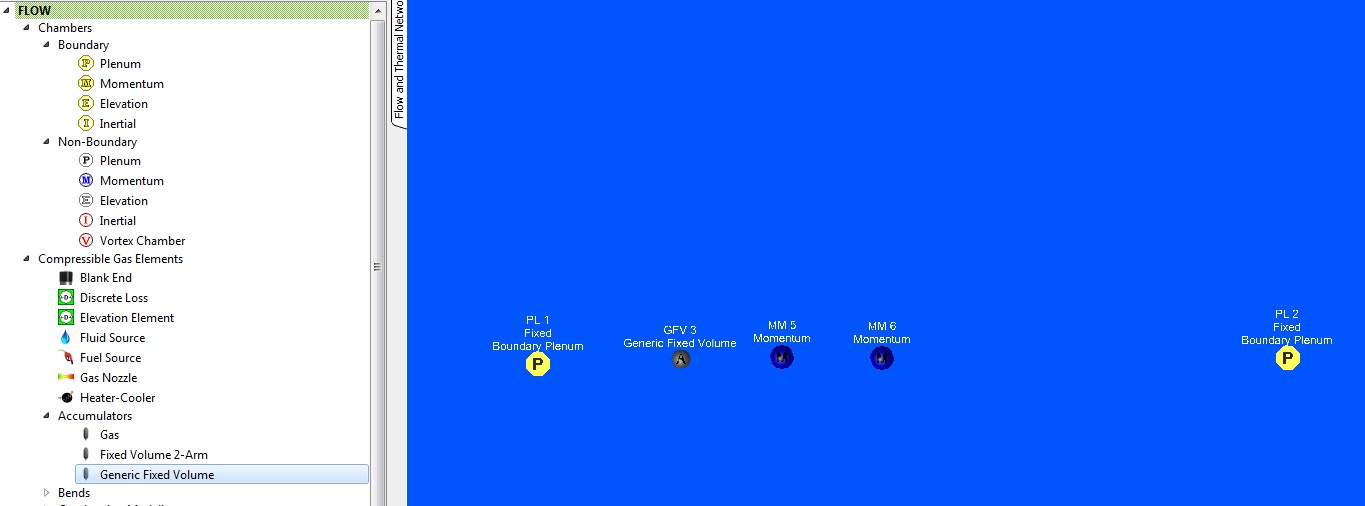

Step 2: Building Model

- Create Chambers (2 Boundary Plenum and 2 Internal Momentum) and the

Accumulator

Figure 1.02: Chamber and Accumulator

- Create Elements: 1 Conventional Orifice, 2 Standard Tubes, and 1 Ball Valve

Figure 1.03: Elements

- Create Feed Forward Controller

Figure 1.04: Feed Forward Controller

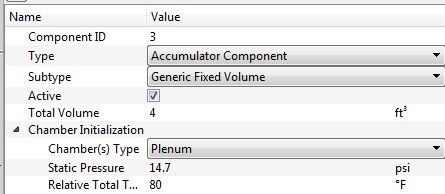

- Assign Chamber Pressure and Temperature

- Upstream Boundary Plenum: P= 400 psi, T= 80 F

- Downstream Boundary Plenum: P= 14.7 psi, T= 80 F

-

2 Internal Momentum: Ptotal = 14.7 psi and Pstatic = 14.7 psi, T=80F.

These are the initial conditions for the transient.

- Assign Accumulator Properties: Total Volume = 4 ft3

- Chamber Initialization for the accumulator: Plenum, Pstatic = 14.7 psi, T = 80F

Figure 1.05: Accumulator Properties

- Assign Element properties

- Orifice: Area = 0.05 in2

- Upstream Tube: Dia = 1 in., Length = 1 ft, Heat Transfer = Adiabatic

- Downstream Tube: Dia = 1 in, Length = 100 ft, Heat Transfer = Adiabatic

- Ball Valve: Pipe Dia = 1 in, Valve Position = 0% open (controller will adjust this)

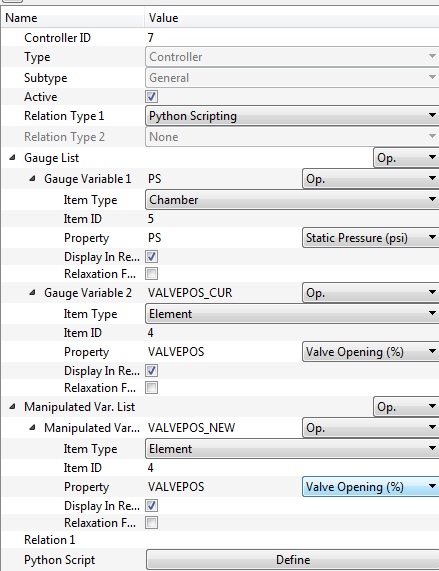

- Assign Feed Forward Controller Properties

- Controller will use a python script.

# Valve position will be set to 100% open if the upstream pressure> 400 psi.

# After the valve position is 100% open it will stay 100% open until the run ends.

if VALVEPOS_CUR == 0.0:

if PS > 400:

VALVEPOS_NEW=100

else:

VALVEPOS_NEW=0

else:

VALVEPOS_NEW=100

- Controller will use a python script.

- Copy and Paste or retype the text. Lines with # are comments. Python uses indentation to identify control logic (if and else statements).

- 2-gauge variables: Upstream pressure and the ball valve position

- Ball valve position will be used as a gauge and manipulated variable.

- 1 manipulated variable: the ball valve position

Figure 1.06: FFWD Controller properties

- Analysis Setup:

- Analysis Type: Transient Flow

- Initial Condition Option: User-defined Pressure and Temperature Data

- Solver will use P and T that have been assigned to the 2 internal momentum chambers and the accumulator for the time = 0 sec. solution.

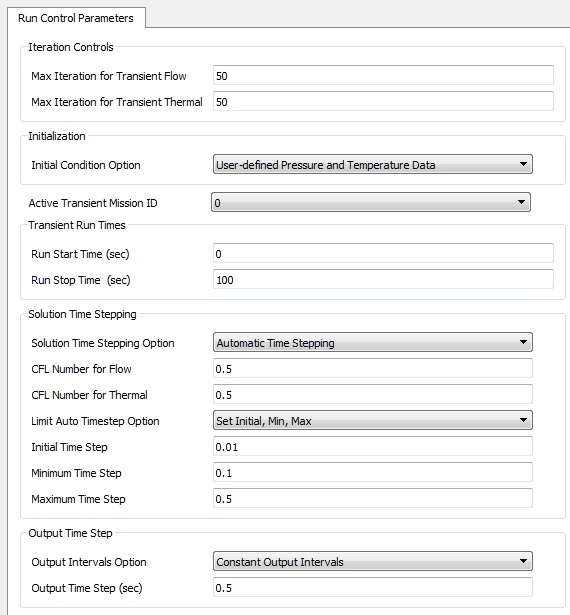

- Transient Run Control Parameters (Figure 1.07)

- Run Start Time: 0 sec

- Run Stop Time: 100 sec

- Solution Time Step Option: Automatic Time Stepping

- Initial, Minimum and Maximum Time Step: 0.01, 0.1, 0.5 sec

- Output Time Step Option: Constant Output Intervals

- Output Time Step: 0.5 sec

Figure 1.07: Transient Run Control Parameters

Step 3: Check Model and Run

- Select checkmark icon from the top toolbar

to check the model for warnings/errors.

to check the model for warnings/errors.- No errors or warnings should appear.

- Select run icon from toolbar

. Run Flow Simulator.

. Run Flow Simulator.

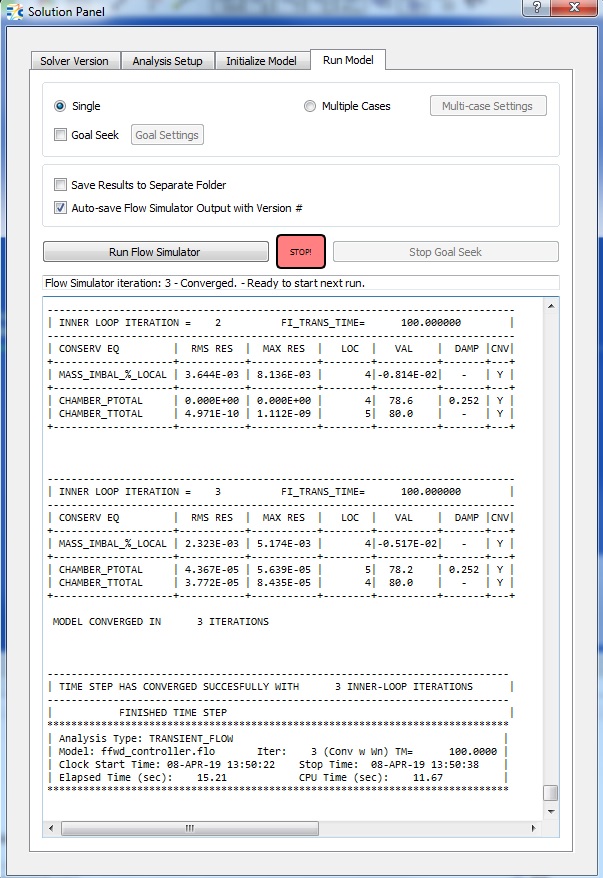

Figure 1.08: Run Panel

Step 4: Post-process

- The first results file (*.res) of the transient should automatically be loaded into GUI. If not, it can be selected via File → Load Result File

- By default, both chamber and elemental results are displayed in the graphical

workspace.

Figure 1.09: Results at 0.5 seconds

- Use the Results Table for post processing results Versus Time.

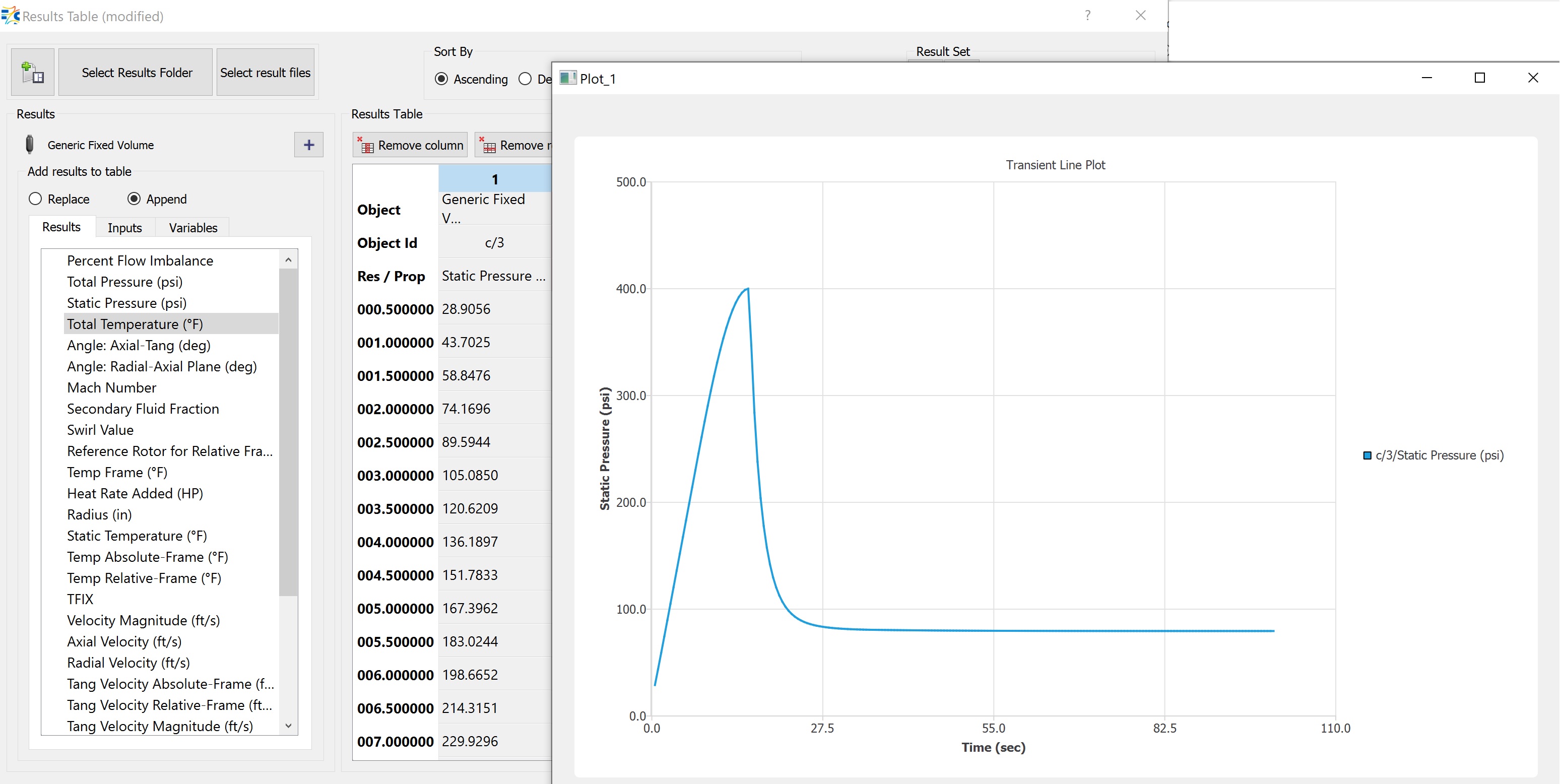

- Pick the Accumulator Static Pressure

Figure 1.10: Accumulator Static Pressure versus Time

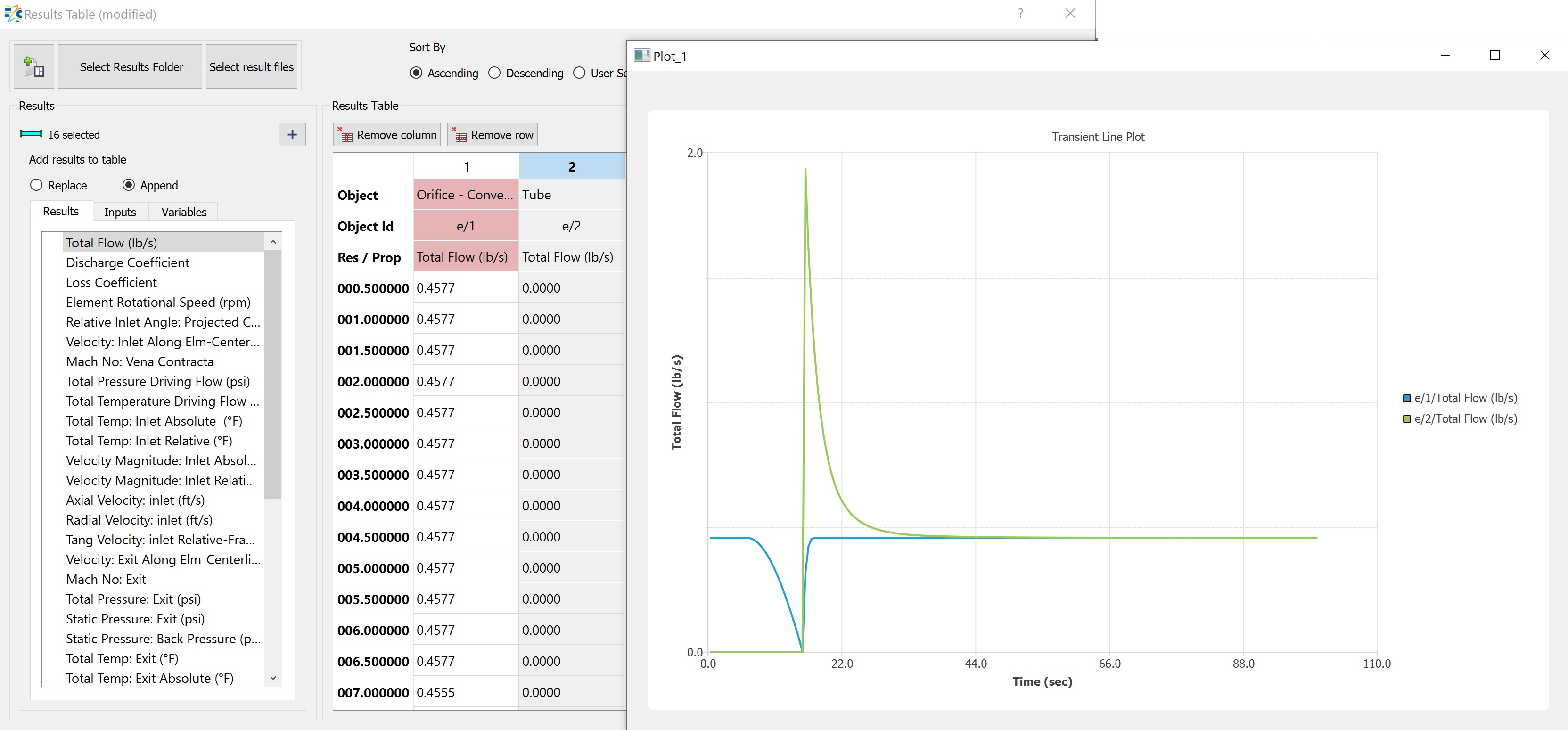

- Pick the Orifice element upstream of the accumulator and the tube downstream

and plot Total Flow

Figure 1.11:

- Pick the Accumulator Static Pressure