Tutorial 17: User Defined Element

Purpose/Objective

This exercise will walk the user through building a simple flow model using UDE to represent a restriction in the flow.

The user will learn how to:

- Create UDE element with its own Properties

- Implement Python/Fortran Code for the flow equations

- Edit chamber properties

- Check the model

- Run the model

- Post-process the model

- Chamber Types: Plenum

- Element Types: UDE

- Fluid: Air

Step 1: Building Model

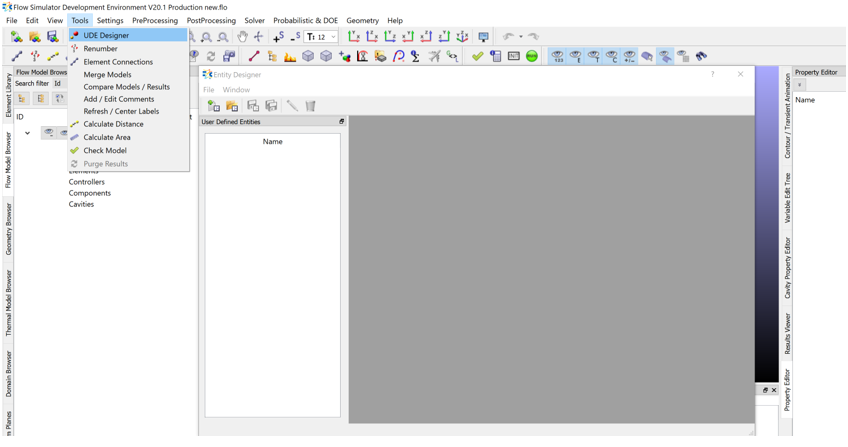

- Open UDE Designer window from Tools → UDE Designer

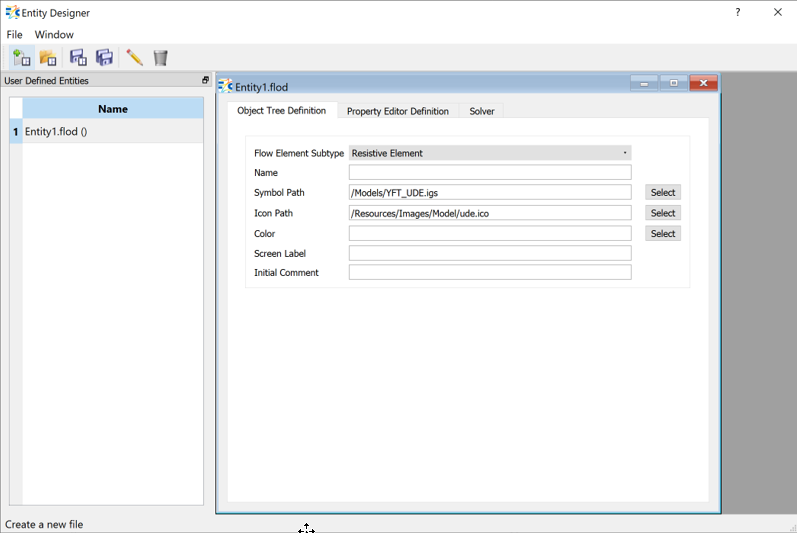

- Create New UDE File by clicking on New (if there is predefined UDE you can also

open it from Open)

- Select Element Subtype as Resistive Element

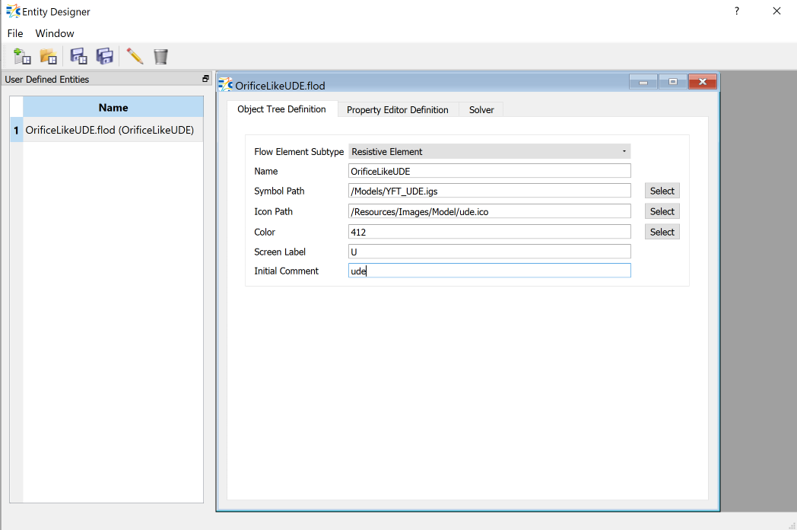

- Give a name (OrificeLikeUDE)

- Select Symbol Path “/Models/YFT_UDE.igs”

- Select Icon Path “/Resources/Images/Model/ude.ico”

- Select color to distinguish UDE element from other elements

- Save .flod file

- Add Properties of the UDE element under Property Editor Definition tab

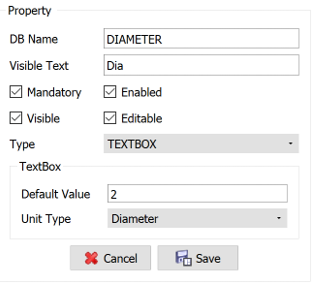

- DIAMETER: Dia as TEXTBOX with Default value of 2 and Unit Type of

Diameter and SAVE

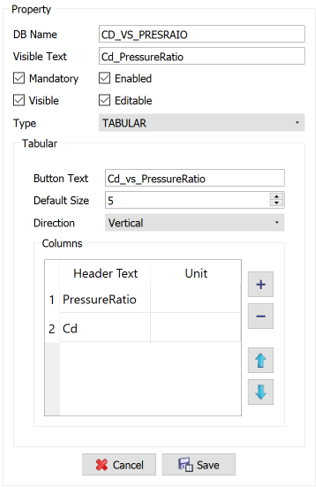

- CD vs Pressure Ratio: Cd_PressureRatio as TABULAR with Default size of 5

and Direction Vertical. Click + to define headers for Pressure Ratio and

Cd and then again SAVE

- For Python Based UDE → Select Solver Language as Python & Write Flow

Function and Error Traps

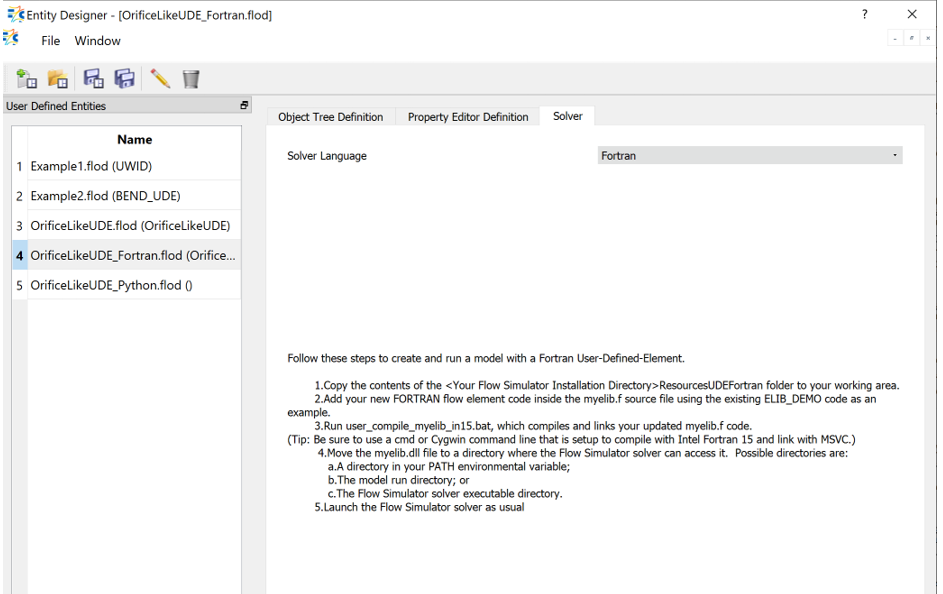

# Get user defined properties DIA = ude.get_scalar_property('DIAMETER') # Get required properties PTS = ude.get_boundary_condition(ude.PTS) # upstream pressure (psia) PSEB = ude.get_boundary_condition(ude.PSEB) # downstream static pressure (psia) RHO_INLET = ude.get_fluid_property(ude.RHO_INLET) # upstream density (lbm/ft^3) MU_INLET = ude.get_fluid_property(ude.MU_INLET) # upstream viscosity (lbm/hr/ft) RHO_EXIT = ude.get_fluid_property(ude.RHO_EXIT) # downstream density (lbm/ft^3) MU_EXIT = ude.get_fluid_property(ude.MU_EXIT) # downstream viscosity (lbm/hr/ft) # Get automatically determined flow direction (based on inlet and exit pressures) #flow_direction = ude.get_flow_direction() gc = 32.17405 AREA = 0.25 * math.pi * DIA**2 # in^2 print('area=',AREA,flush=True) PR = PSEB/PTS print('Pressure Ratio=',PR,flush=True) N = int(ude.get_array_property('PRESSURERATIO', ude.UDE_ARRAY_SIZE) + 1e-6) print('number=', N, flush=True) for I in range(2,N+1): PR_PREV = ude.get_array_property('PRESSURERATIO', I-1) PR_NEXT = ude.get_array_property('PRESSURERATIO', I) CD_PREV = ude.get_array_property('CD', I-1) CD_NEXT = ude.get_array_property('CD', I) if ((PR_PREV <= PR) & (PR <= PR_NEXT)): U = (PR - PR_PREV) / (PR_NEXT - PR_PREV) CD_calc = (1.0 - U) * CD_PREV + U * CD_NEXT break elif ((I == 1) & (PR <= PR_PREV)): CD_calc = CD_PREV break elif (PR_NEXT < 0.001): CD_calc = CD_PREV break elif (I == N): CD_calc = CD_NEXT break if (CD_calc < 0.001): CD_calc = 0.1 print('cd_calculated=', CD_calc,flush=True) # Incompressible liquid mdot = AREA * CD_calc * math.sqrt(2.0 * gc * RHO_EXIT * (PTS - PSEB) / 144.0) ude.set_solved_value(ude.MDOT1, mdot) ude.set_extra_result('CD_RESULT' , CD_calc, '(unitless)') - For Fortran Based UDE → Select Solver Language as Fortran and follow the

steps given there

- Update myelib.f code in UDE_SOLVER

subroutine

DIA = GET_UDE_SCALAR_PROPERTY (UDE_ELNUM, 'DIAMETER' , ISTATUS) ! Get required properties ! Retrieve the element-aligned source total pressure (PTS), which is updated every iteration PTS = GET_UDE_BOUNDARY_CONDITION(UDE_ELNUM, UDE_PTS , ISTATUS) ! Retrieve the element source total temperature (TTS), which is updated every iteration TTS = GET_UDE_BOUNDARY_CONDITION(UDE_ELNUM, UDE_TTS , ISTATUS) ! Retrieve the element sink static pressure (PSEB), which is updated every iteration PSEB = GET_UDE_BOUNDARY_CONDITION(UDE_ELNUM, UDE_PSEB , ISTATUS) ! Retrieve the fluid density at element exit (RHO_EXIT), which is updated every iteration, along with other properties RHO = GET_UDE_FLUID_PROPERTY (UDE_ELNUM, UDE_RHO_EXIT, ISTATUS) AREA = 0.25 * 3.14D0 * DIA**2 ! in^2 PR = PSEB/PTS N = N = GET_UDE_ARRAY_PROPERTY(UDE_ELNUM, 'PRESSURERATIO', UDE_ARRAY_SIZE, ISTATUS) DO I = 2, N PR_PREV = GET_UDE_ARRAY_PROPERTY(UDE_ELNUM, 'PRESSURERATIO', I-1, ISTATUS) PR_NEXT = GET_UDE_ARRAY_PROPERTY(UDE_ELNUM, 'PRESSURERATIO', I , ISTATUS) CD_PREV = GET_UDE_ARRAY_PROPERTY(UDE_ELNUM, 'CD', I-1, ISTATUS) CD_NEXT = GET_UDE_ARRAY_PROPERTY(UDE_ELNUM, 'CD', I , ISTATUS) IF (PR_PREV <= PR .AND. PR <= PR_NEXT) THEN U = (PR - PR_PREV) / (PR_NEXT - PR_PREV) CD_calc = (1.0D0 - U) * CD_PREV + U * CD_NEXT EXIT ELSEIF (I == 1 .AND. PR <= PR_PREV) THEN CD_calc = CD_PREV ! If PR is off the low end of the lookup-table, use the leftmost CD value EXIT ELSEIF (PR_NEXT < 1D-3) THEN CD_calc = CD_PREV ! If PR is off the high end of the lookup-table, then use the rightmost CD value EXIT ELSEIF (I == N) THEN CD_calc = CD_NEXT ! If PR is off the high end of the lookup-table, then use the rightmost CD value EXIT ENDIF ENDDO MDOT = CD_calc * (AREA / 144.0D0) * RHO * DSQRT(2.0D0 * 12.0D0 * GC * (PTS - PSEB) / RHO) ! Set flow rate for one stream (MDOT1) so it will be returned to the main solver. This is required. CALL SET_UDE_SOLVED_VALUE(UDE_ELNUM, UDE_MDOT1 , MDOT , ISTATUS) ! Set TT_EXIT equal to TTS, which is adiabatic. In fact, adiabatic is the default, so you don't really need this line. CALL SET_UDE_SOLVED_VALUE(UDE_ELNUM, UDE_TT_EXIT , TTS , ISTATUS) ! SET_UDE_EXTRA_RESULT submits a variable that is not needed by the solver to the results print-out so you can see it CALL SET_UDE_EXTRA_RESULT(UDE_ELNUM, 'CD_RESULT', CD_calc, '(unitless)', ISTATUS) - Add 2 Plenum Chambers:

- Upstream Plenum Chamber: Ps = 10 psi, Ts = 80F

- Downstream Plenum Chamber: Ps = 2 psi, Ts = 80F

- Drag and Drop OrificeLikeUDE between the Plenum chambers and connect

- Diameter = 2 in

- Pressure Ratio vs CD Table as

PRESSURERATIO CD 0.1 0.1 0.5 0.2 1.0 0.3 2.5 0.4 5 0.5

- DIAMETER: Dia as TEXTBOX with Default value of 2 and Unit Type of

Diameter and SAVE

Step 2: Check Model and Run

- Select check mark icon from the top toolbar

to check the model for

warnings/errors.

to check the model for

warnings/errors. - Select run icon from toolbar

. Run Flow Simulator.

. Run Flow Simulator. - Outputs of the “print()” functions can be seen on the Run Window

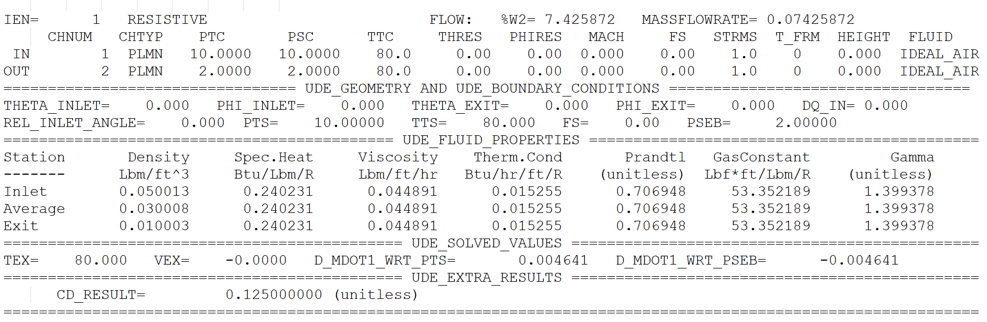

Step 3: Post-process

- Results file (*.res) should be generated in model running directory.

- open the result file (*.res) and search for UDE element. Results for UDE will have following data