The Powders Starter Pack

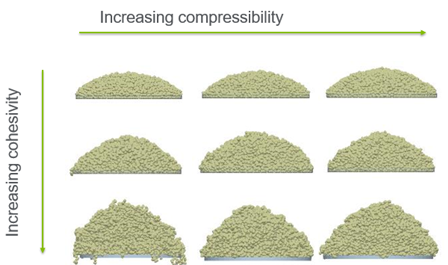

The Powders Starter Pack consists of nine material models with the following range of behaviors.

The Powder starter pack naming convention refers to the compressibility and flow properties from the Angle of Repose tests.

The simulation decks can be found in the following installation directory:

C:\Program Files\Altair\<EDEM version>\EDEM\examples\Powder Start

Pack.

To use these material models in a simulation, copy them into the Material library or modify the simulation deck provided.

Material Properties

| Material | Untapped Bulk Density (kg/m3) | Tapped Bulk Density (kg/m3) | Angle of Repose (degrees) | Compressibility | Flow Character |

|---|---|---|---|---|---|

| 1 | 678 | 733 | 27.5 | Incompressible | Excellent |

| 2 | 675 | 715 | 29 | Compressible | Excellent |

| 3 | 676 | 711 | 28.5 | Very compressible | Excellent |

| 4 | 604 | 659 | 39 | Incompressible | Fair |

| 5 | 619 | 662 | 37 | Compressible | Fair |

| 6 | 613 | 650 | 35 | Very compressible | Fair/Good |

| 7 | 514 | 593 | 50+ | Incompressible | Poor |

| 8 | 523 | 628 | 50+ | Compressible | Poor |

| 9 | 532 | 637 | 50+ | Very Compressible | Poor |

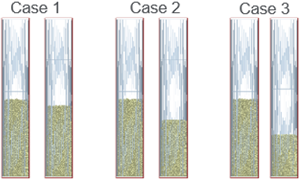

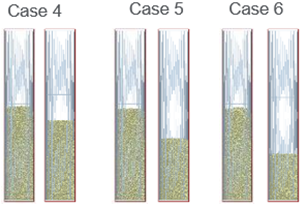

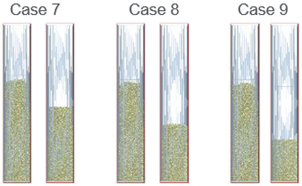

| Non-compressible | Mid-compressible | Highly-compressible | |

|---|---|---|---|

| Non-cohesive | Case 1 | Case 2 | Case 3 |

| Mid-cohesive | Case 4 | Case 5 | Case 6 |

| Highly-cohesive | Case 7 | Case 8 | Case 9 |

| Case | Sample height before compression (mm) | Sample height after compression (mm) | Amount of compression (%) | Compression Ratio | Carr Index (%) | Hausner Ratio | Flow Character |

|---|---|---|---|---|---|---|---|

| 1 | 91 | 83 | 0.09 | 1.1 | 7.5 | 1.08 | Excellent |

| 2 | 91 | 66 | 0.28 | 1.4 | 5.59 | 1.06 | Excellent |

| 3 | 91 | 49 | 0.47 | 1.9 | 4.92 | 1.05 | Excellent |

| 4 | 102 | 87 | 0.15 | 1.2 | 8.34 | 1.09 | Excellent |

| 5 | 100 | 67 | 0.33 | 1.5 | 6.49 | 1.07 | Excellent |

| 6 | 101 | 50 | 0.5 | 2 | 5.69 | 1.06 | Excellent |

| 7 | 120 | 88 | 0.27 | 1.4 | 13.32 | 1.15 | Good |

| 8 | 118 | 67 | 0.43 | 1.8 | 16.71 | 1.2 | Fair |

| 9 | 116 | 49 | 0.58 | 2.4 | 16.48 | 1.19 | Fair |

Particle-Particle and Particle-Geometry Interactions

The following tables comprise a series of Particle-Particle and Particle-Geometry interactions to obtain the relevant material behavior.

| Powder | EEPA Surface Energy (J/m2) | EEPA Constant pull-off force (N) | EEPA Contact Plasticity Ratio | EEPA Slope Exp | EEPA Tensile Exp | EEPA Tangential Stiffness Multiplier | Material-Material Rolling Friction | Material-Material Static Friction | Material-Material Restitution |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0.1 | 1.5 | 5 | 0.28571 | 0 | 0.3 | 0.5 |

| 2 | 0 | 0 | 0.5 | 1.5 | 5 | 0.28571 | 0 | 0.3 | 0.5 |

| 3 | 0 | 0 | 0.9 | 1.5 | 5 | 0.28571 | 0 | 0.3 | 0.5 |

| 4 | 0.05 | -5.00E-05 | 0.1 | 1.5 | 5 | 0.28571 | 0.02 | 0.6 | 0.5 |

| 5 | 0.05 | -5.00E-05 | 0.5 | 1.5 | 5 | 0.28571 | 0.02 | 0.6 | 0.5 |

| 6 | 0.05 | -5.00E-05 | 0.9 | 1.5 | 5 | 0.28571 | 0.02 | 0.6 | 0.5 |

| 7 | 0.25 | -0.0001 | 0.1 | 1.5 | 5 | 0.28571 | 0.1 | 0.84 | 0.5 |

| 8 | 0.25 | -0.0001 | 0.5 | 1.5 | 5 | 0.28571 | 0.1 | 0.84 | 0.5 |

| 9 | 0.25 | -0.0001 | 0.9 | 1.5 | 5 | 0.28571 | 0.1 | 0.84 | 0.5 |

| Powder | Material-Geometry Rolling Friction | Material-Geometry Static Friction | Material-Geometry Restitution |

|---|---|---|---|

| 1 | 0.15 | 0.36 | 0.5 |

| 2 | 0.15 | 0.36 | 0.5 |

| 3 | 0.15 | 0.36 | 0.5 |

| 4 | 0.15 | 0.84 | 0.5 |

| 5 | 0.15 | 0.84 | 0.5 |

| 6 | 0.15 | 0.84 | 0.5 |

| 7 | 0.15 | 1.4 | 0.5 |

| 8 | 0.15 | 1.4 | 0.5 |

| 9 | 0.15 | 1.4 | 0.5 |

Research has shown that values of Carr Index below 15% indicate very good flow character but values above 25% indicate poor flow. Also, Hausner ratio values of around 1.00–1.25 indicate free-flowing powder, values between 1.26–1.45 indicate poor flow, and above 1.46 are related to extremely poor flow (Carr (1965), Wells (1988), Marshall (1986). The EDEM tapped density results indicate that the overall flow character of the materials is varied between excellent to fair however, the angle of repose measurements indicates that cases 4-6 have passable flow ability and cases 7-9 have very poor flow ability.

Compressibility test results are displayed as follows: