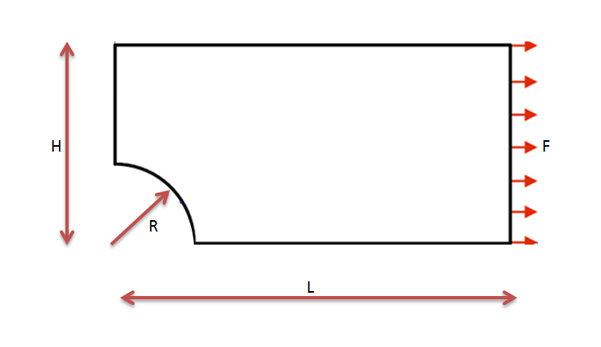

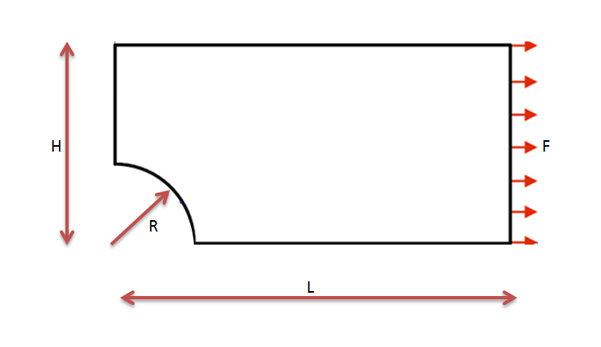

Test No. VS08 Find the maximum stress of a plate with a

hole.

Definition

Figure 1.

Due to symmetry, only ¼ section was analyzed (Figure 1).

The units are SI.

Sliding constraints applied to the left, back, and bottom faces.

The load is 5000N applied to the right face.*

The model parameters are:

- Parameters

- Value

- L

- 100mm

- H

- 50mm

- R

- 20mm

- F

- 100N/mm2

- Thickness

- 1mm

The material properties are:

- Properties

- Value

- Modulus of Elasticity

- 2.1e+11

- Poisson's Ratio

- 0.3

Results

The reference solution is given by:

With k = 3.

The following table summarizes the maximum stress.

|

Theory |

SimSolid |

% Difference |

| Maximum Stress [MPa] |

3.7270E+02 |

3.7746E+02 |

1.28% |

*To determine the load: 100N/mm2 x 50mm x 1mm.