/FAIL/MAXSTRAIN

Block Format Keyword Maximum strain failure criterion for modeling the failure of composite materials. This criterion is available for solids and shells.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/MAXSTRAIN/mat_ID/unit_ID | |||||||||

| Ifail_sh | Ifail_so | ||||||||

| Fcut | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

| Longitudinal critical

strain. Default = 1020 (Real) |

||

| Transverse critical

strain. Default = 1020 (Real) |

||

| Shear critical engineering

strain. Default = 1020 (Real) |

||

| Ifail_sh | Shell failure model flag.

(Integer) |

|

| Ifail_so | Solid failure model flag.

(Integer) |

|

| Dynamic time relaxation. 5 Default = 1020 (Real) |

||

| Fcut | Stress tensor filtering

frequency. Default = 0.0 (Real) |

|

| fail_ID | (Optional) Failure criteria

identifier.4

(Integer, maximum 10 digits) |

Example

/UNIT/1

Mg mm s

/FAIL/MAXSTRN/1/1

# EPS1_MAX EPS2_MAX GAM12_MAX IFAIL_SH IFAIL_SO

0.052 0.045 0.0157 1 1

# TAU_MAX FCUT

1.0E-4 100.0ZZComments

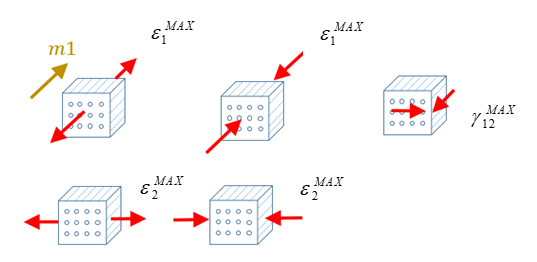

- This failure model is available for shells and solids. It considers

a composite ply with the fibers oriented in the direction 1 (also denoted as

m1) and the matrix oriented in transverse direction 2 (and 3 for solids).

Each direction considers a critical strength value valid for both tension

and compression:

Figure 1.Where, , , are respectively the critical strain in direction 1, critical strain in direction 2 and critical engineering strain in shear.Note:Where, is the shear strain.

- The failure criterion for shells is written as:

(1) For solids the criterion becomes:(2) The criterion is considered to be reached when . The damage variable corresponds to the criterion itself .

- Once the criterion is

reached

, two behaviors can be set up:

- If Ifail_sh = 0 or Ifail_so = 0, there is no stress softening and elements are never deleted. In this case, the failure criterion is purely visual using the output of the damage variable.

- If Ifail_sh ≠

0 or

Ifail_so ≠

0, a stress relaxation is generated to decrease

the load carrying capacity of the element.

(3) With and .

Where,- Time.

- Start time of relaxation when the damage criteria is assumed.

- Time of dynamic relaxation.

- Stress tensor when the criterion is reached.

When the stresses reach 1% of the stress value at the beginning of the failure, the element is deleted. This is necessary to avoid instabilities coming from a sudden deletion of an element and a failure “chain reaction” in the neighboring elements. Even if the failure criterion is reached, there will be no element deletion with the default value of . Therefore, it is recommended to define a value for 10 times larger than the simulation time step.

- To avoid “chain

reaction” when deleting elements, you can also define a stress tensor

filtering frequency Fcut. Thus, the stress tensor used to calculate the MAXSTRAIN criterion is

first to be filtered according to:

(4) With

Where, is the current timestep.

If a filtering frequency is not defined (Fcut= 0.0), the filtering effect is deactivated.

- The fail_ID is used with /STATE/BRICK/FAIL and /INIBRI/FAIL. There is no default value. If the line is blank, no value will be output for failure model variables in the /INIBRI/FAIL (written in .sta file with /STATE/BRICK/FAIL option).