| Damage criteria |

If

=1, then failure. If

,

then no failure. With

|

If

=1, then failure. If

,

then no failure. With

|

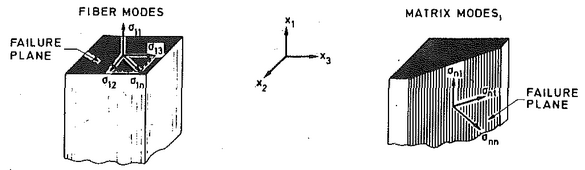

| Tensile/shear fiber mode |

|

With,

|

| Compression fiber mode |

With

|

With

With

|

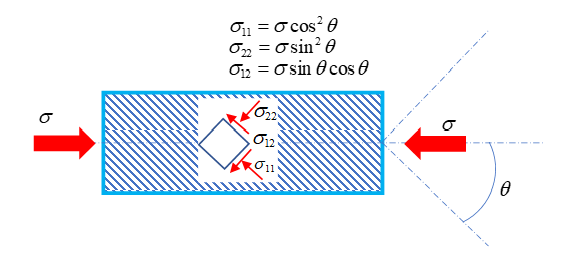

| Crush mode |

With

|

With

|

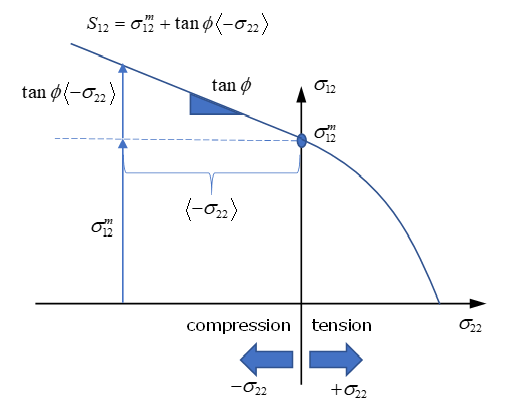

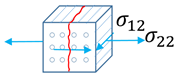

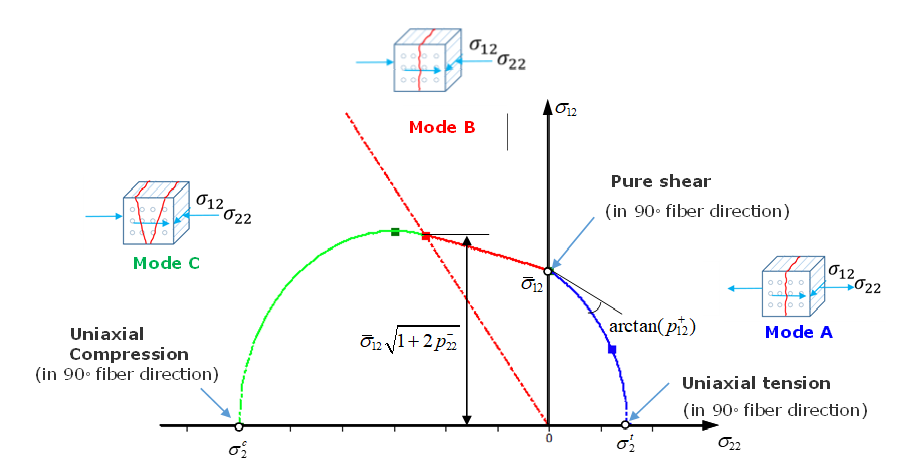

| Shear failure matrix mode |

|

|

| Failure matrix mode |

Where,

|

|

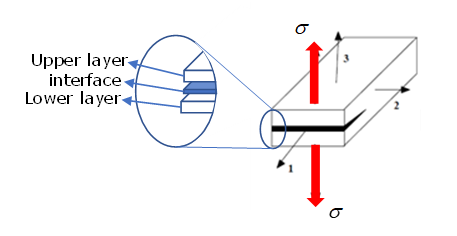

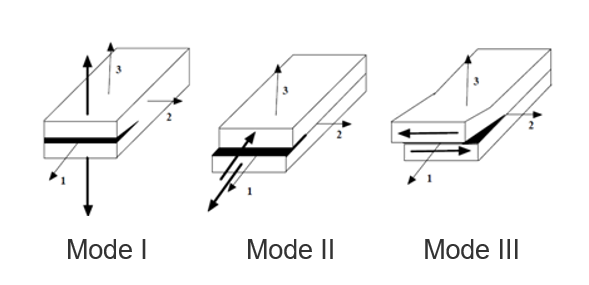

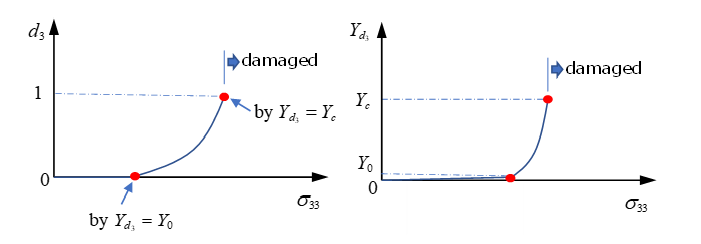

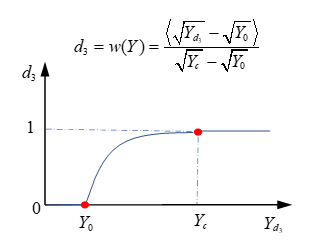

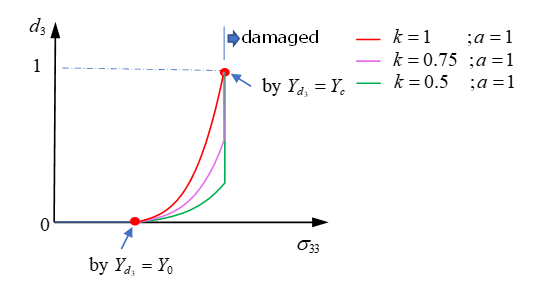

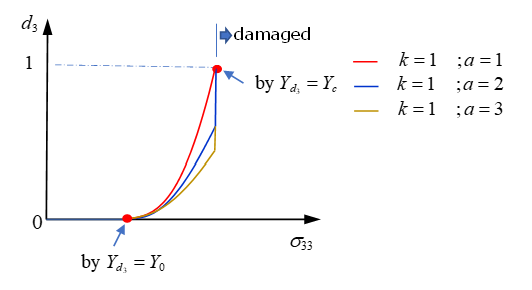

| Delamination mode |

Where,

|

Where,

|