/FAIL/TAB2

Block Format Keyword This advanced failure model allows the plastic strain at failure to be defined as a function of stress triaxiality, strain rate, Lode angle, element size, and temperature.

A coupling with stress computation generating a stress softening is also available through different features. It can be fully coupled or triggered by other phenomena like instability strain to control necking. Damage is accumulated based using an exponent evolution. This criterion is compatible with both solids and shells and can be used with non-local regularization.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/TAB2/mat_ID/unit_ID | |||||||||

| EPSF_ID | FCRIT | FAILIP | PTHICKFAIL | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| N | DCRIT | INST_ID | ECRIT | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FCT_EXP | EXP_REF | EXP | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| TAB_EL | IREG | EL_REF | SR_REF1 | FSCALE_EL | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| SHRF | BIAXF | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FCT_SR | SR_REF2 | FSCALE_SR | C_JCOOK | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FCT_DLIM | FSCALE_DLIM | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit Identifier. (Integer, maximum 10 digits) |

|

| EPSF_ID | Plastic strain at failure table

identifier. (Integer) |

|

| FCRIT | Scale factor for failure plastic

strain table. Default = 1.0 (Real) |

|

| FAILIP | Number of failed integration point

prior to solid element deletion. Defaut = 1 (Integer) |

|

| PTHICKFAIL | Percentage of failed layers prior

to shell element deletion. Default = 0.0 (Real) |

|

| N | Damage accumulation

exponent. Default = 1.0 (Real) |

|

| DCRIT | Critical damage for stress

softening triggering. Default = 0.0 (Real) |

|

| INST_ID | Instability (necking) plastic

strain table identifier. (Integer) |

|

| ECRIT | Scale factor for necking plastic

strain table identifier. (Real) |

|

| FCT_EXP | Stress softening exponent function

identifier. (Integer) |

|

| EXP_REF | Reference element size for stress

softening exponent function. Default = 1.0 (Real) |

|

| EXP | Scale factor for stress softening

exponent function. Default = 1.0 (Real) |

|

| TAB_EL | Element size scaling table

identifier. (Integer) |

|

| IREG | Element size regularization flag.

(Integer) |

|

| EL_REF | Reference element size for size

scaling table. Default = 1.0 (Real) |

|

| SR_REF1 | Reference strain rate for size

scaling table. Default = 1.0 (Real) |

|

| FSCALE_EL | Scale factor for element size

scaling function. Default = 1.0 (Real) |

|

| SHRF | Lower stress triaxiality boundary

for element size scaling. Default = -1.0 (Real) |

|

| BIAXF | Upper stress triaxiality boundary

for element size scaling. Default = 1.0 (Real) |

|

| FCT_SR | Strain rate dependency function

identifier. (Integer) |

|

| SR_REF2 | Reference strain rate for strain

rate dependency function. Default = 1.0 (Real) |

|

| FSCALE_SR | Scale factor for strain rate

dependency function. Default = 1.0 (Real) |

|

| C_JCOOK | Johnson-Cook strain rate dependency

factor. Default = 0.0 (Real) |

|

| FCT_DLIM | Damage limit function

identifier. (Integer) |

|

| FSCALE_DLIM | Damage limit function scale

factor. Default = 1.0 (Real) |

|

| fail_ID | (Optional) Failure criteria

identifier. 9 (Integer, maximum 10 digits) |

Example (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel

# RHO_I

7.8E-6 0

# E Nu Iflag

210 .3 0

# a b n EPS_p_max SIG_max0

.4 .5 .5 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0 0 0 0 0 0

# m T_melt rhoC_p T_r

0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FAIL/TAB2/1/1

# EPSF_ID FCRIT FAILIP PTHICKFAIL

52 0.9 0 1.0

# N DCRIT INST_ID ECRIT

2.0 0 53 0.5

# FCT_EXP EXP_REF EXP

0 0 2.5

# TAB_EL IREG EL_REF SR_REF1 FSCALE_EL

0 0 0 0 0

# SHRF BIAXF

0 0

# FCT_SR SR_REF2 FSCALE_SR C_JCOOK

0 0 0 0

# FCT_DLIM FSCALE_DLIM

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/52

epsf vs triax

-0.333 3.009955556

-0.3 2.728211

-0.25 2.33840625

-0.2 1.987976

-0.15 1.67692025

-0.1 1.405239

-0.05 1.17293225

0 0.98

0.05 0.82644225

0.1 0.712259

0.15 0.63745025

0.2 0.602016

0.25 0.60595625

0.3 0.649271

0.333 0.700985898

0.35 0.663237826

0.4 0.567983816

0.45 0.496266718

0.5 0.448086532

0.55 0.423443259

0.577 0.419921961

0.6 0.428924499

0.625 0.459765672

0.65 0.512542413

0.666 0.559913333

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/53

0.333 0.700985898

0.35 0.647131801

0.4 0.511235623

0.45 0.408918886

0.5 0.34018159

0.55 0.305023734

0.577350269 0.3

0.6 0.316714456

0.625 0.373975356

0.65 0.471962671

0.666666667 0.559913333

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The

/FAIL/TAB2 failure criterion is a tabulated criterion

that offers you the freedom to define your own map of plastic strain at

failure with stress triaxiality, Lode parameter and other dependency. This

plastic strain at failure is used to compute a damage variable evolution

described below. This criterion also offers the possibility to generate a

stress softening effect with the damage computation as:

(1) Where,- Damaged stress tensor.

- Undamaged effective stress tensor.

- Critical damage value that triggers stress softening.

- Exponent parameter.

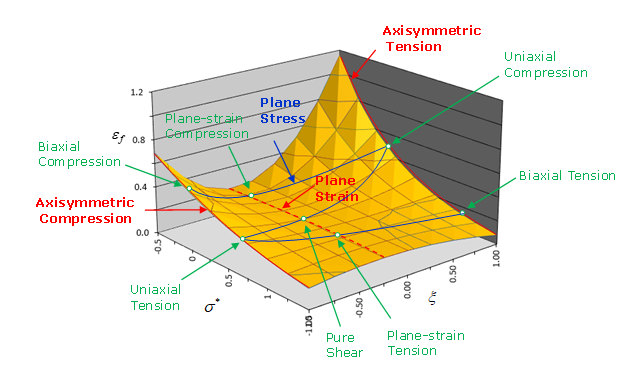

- To use /FAIL/TAB2, it is required to define a

plastic strain at failure used to compute the damage accumulation presented

below. It can be either constant using FCRIT parameter

alone or tabulated if EPSF_ID table identifier is

specified. The tabulated plastic strain at failure is defined with respect

to stress triaxiality, Lode parameter and temperature

(Figure 1). If EPSF_ID is defined, FCRIT becomes a scale factor to quickly increase or decrease the entire plastic strain at failure map.

Figure 1. Tabulated failure criterion map showing the

evolution of plastic strain at failure with respect to stress

triaxiality and Lode parameter

Figure 1. Tabulated failure criterion map showing the

evolution of plastic strain at failure with respect to stress

triaxiality and Lode parameter - FAILIP is an integer value that is used only with higher order or fully-integrated solid elements. It defines the number of failed integration points prior to solid element deletion.

- PTHICKFAIL parameter is a real parameter used for

shell elements. If PTHICKFAIL is blank or set to 0.0, the

value of PTHICKFAIL from the shell property is used. If

PTHICKFAIL > 0.0, any PTHICKFAIL

value defined in the shell properties are ignored and the value entered in

this failure model is used.

For values of PTHICKFAIL > 0.0, shell elements fail and are deleted when the ratio of through thickness failed integration points equals or exceeds PTHICKFAIL.

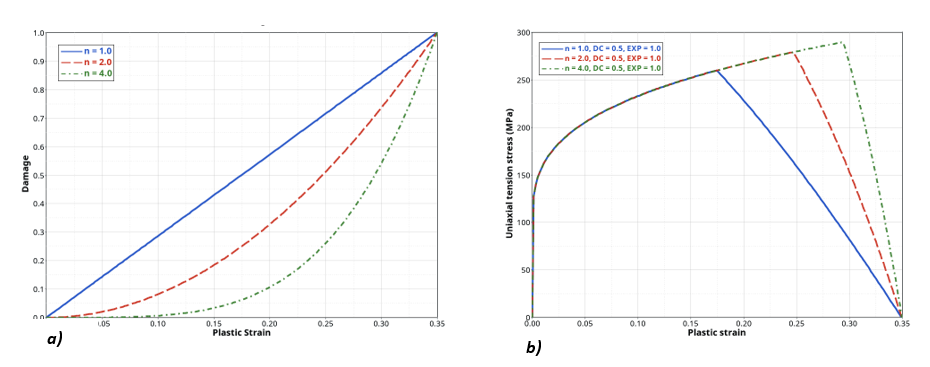

- The damage variable evolution is given by:

(2) The parameter N then allows you to change the shape of the damage evolution with plastic strain shape from linear (N = 1, set by default) to nonlinear (N ≠ 1) (Figure 2(a)). An increase of N also creates a delay of the stress softening effect (Figure 2(b)).

Figure 2. Effect of parameter N on the damage variable

evolution and the stress softening effect

Figure 2. Effect of parameter N on the damage variable

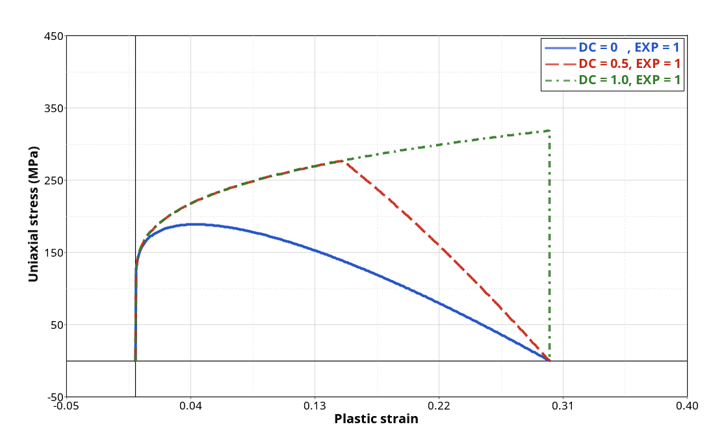

evolution and the stress softening effect - The DCRIT parameter allows you to define a damage

variable trigger value for stress softening (Figure 3). By default DCRIT

= 0.0, which means that damage variable always has an effect on stress

computation, generating a softening effect from the beginning of the

plasticity. However, you may want to delay this stress softening effect to a

higher value of damage variable (0 < D < 1) or cut the effect of

stress softening to obtain a fully failure criterion approach where elements

lose their load carrying capacity when damage reaches the value 1.

Figure 3. Effect of parameter DCRIT on the stress softening

effect

Figure 3. Effect of parameter DCRIT on the stress softening

effect - Instead of using a constant value of DCRIT to

trigger stress softening, a necking control process can be used. This is

defined using the parameter INST_ID and/or

ECRIT. The definition of those parameters will imply

the computation of another variable evolution called instability variable

and denoted

:

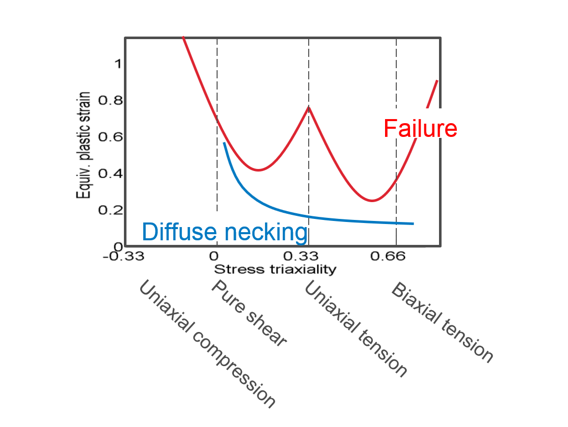

(3) The evolution of this instability variable is similar to the damage variable but represents the criterion to reach to trigger stress softening, implying the start of the strain localization and then necking especially observed at high stress triaxiality. When the criterion is reached ( = 1), the instant value taken by the damage variable D is saved in the value DCRIT, which becomes an element history variable and not a constant value. In this case, the DCRIT value defined in the input card is ignored.

ECRIT allows you to define a constant necking plastic strain. However, the necking plastic strain can be defined with a table INST_ID depending on stress triaxiality, Lode parameter and temperature. In this case, ECRIT becomes a scale factor for the instability plastic strain table. The instability plastic strain must be lower than failure plastic strain to have a visible effect (Figure 4). Figure 4. Necking plastic strain curve (blue) and failure

plastic strain curve (red)

Figure 4. Necking plastic strain curve (blue) and failure

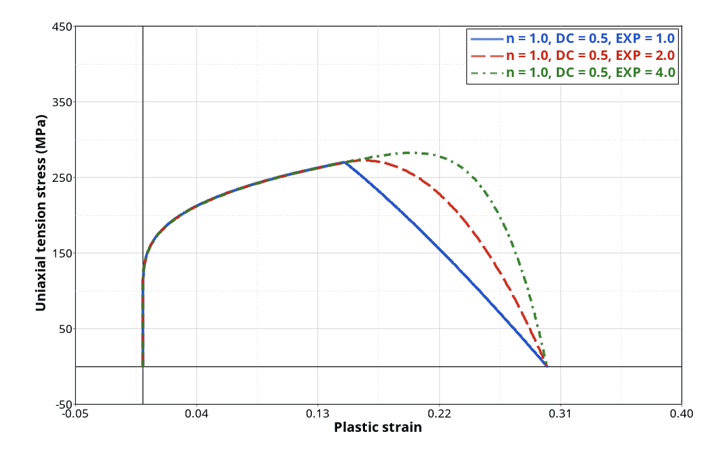

plastic strain curve (red) - Even if the shape of the damage accumulation can be controlled with

parameter N, another non-linearity in stress softening

can be defined with the exponent EXP (Figure 5). This exponent can be constant if

EXP parameter is defined alone or can evolve with

element size if FCT_EXP is specified. If the function is

used, EXP_REF is the element reference size and

EXP becomes a scale factor. By default,

EXP is set to 1.0 leading to a linear decrease.

Figure 5. Effect of exponent parameter EXP on the stress

softening shape

Figure 5. Effect of exponent parameter EXP on the stress

softening shape - Element size scaling can be

used to regularize the failure and ensure an almost constant fracture energy

dissipated with different mesh sizes is obtained. This element size

dependency is introduced by computing a size scale factor denoted

defined by the table

TAB_EL. The dependencies of these tables depend on

the value of the IREG flag:

- IREG = 1: the table defines the evolution of the element size scaling factor with respect to initial element size and strain rate . In this case, EL_REF is the reference element size , and SR_REF1 is the reference strain rate .

- IREG = 2: the table defines the evolution of the element size scaling factor with respect to initial element size and stress triaxiality . In this case, EL_REF is the reference element size , and SR_REF1 is ignored.

In both cases, FSCALE_EL is a scale factor that quickly increases or decreases the values of the entire table. The element size scale factor thus computed is introduced in the damage variable evolution equation (and if defined, the instability variable evolution equation) as:(4) Note: If IREG = 1 is used, the element size scaling can be turned off, if the stress triaxiality is lower than the boundary SHRF, or is higher than the boundary BIAXF. - A strain rate dependency can be also applied to the failure

criterion. This dependency can be introduced in two different ways:

- If FCT_SR ≠ 0, a tabulated function of the strain

rate dependency factor

is used. In this case, you must

define a function to describe the evolution of the strain rate

factor (denoted

) with the strain rate. You can also

input a reference strain rate SR_REF2 denoted

in the equation, and a scale factor. Using

the tabulated strain rate dependency, the damage variable

computation (and if defined, the instability variable evolution

equation) becomes:

(5) - If

, the Johnson-Cook strain rate

dependency is used and SR_REF2 becomes the

reference strain rate

. In this case, the plastic strain at

failure value is multiplied by the strain rate dependency factor

as:

(6) Where,- Inviscid limit strain rate.

- Strain rate dependency parameter.

- Macaulay brackets, which consider only positive values.

If you are using a Johnson-Cook material law coupled to the /FAIL/TAB2 criterion, the Johnson-Cook parameters used for the constitutive law might not be the same for the failure criterion. The reference strain rate used in the presented equation is different from the one used for element size scaling when IREG = 1.

Important: The strain rate dependency applied to the failure criterion can only be used with material laws that are strain rate dependent. The strain rate used for the constitutive law (total strain rate, deviatoric strain rate or plastic strain rate), will be the same used for the failure criterion.

- If FCT_SR ≠ 0, a tabulated function of the strain

rate dependency factor

is used. In this case, you must

define a function to describe the evolution of the strain rate

factor (denoted

) with the strain rate. You can also

input a reference strain rate SR_REF2 denoted

in the equation, and a scale factor. Using

the tabulated strain rate dependency, the damage variable

computation (and if defined, the instability variable evolution

equation) becomes:

- The stress softening can be restricted to a given range of stress triaxiality. To do so, a damage limit value (lower than 1 for which the element has lost its load carrying capacity) evolving with stress triaxiality may be defined using the function FCT_DLIM. Values taken by this function must be taken between 0 and 1. A scale factor can be used to quickly increase or decrease the entire function values.

- If the non-local regularization is used (/NONLOCAL/MAT), the non-local plastic strain is used to compute the damage evolution (and the instability variable if used). In that case, if an element size scaling is defined through TAB_EL or an element size dependent exponent parameter function FCT_EXP is used, the maximum non-local length parameter LE_MAX is used instead of the initial element size.