RD-E: 4602 Euler Formulation

The purpose of this example is to show how to simulate the cylinder expansion test and compare the simulation result to experimental data.

Figure 1.

Detonation is initiated at the bottom of the explosive. Radial expansion of the cylinder is measured and compared to experimental data.

- Multi-material

- Euler property formulation with Iale=2

- Brick elements

Options and Keywords Used

- Multi-Material Solid, Liquid, and Gas material law (/MAT/LAW51 (MULTIMAT))

- Solid property (/PROP/TYPE14 (SOLID))

- Boundary condition (/BCS)

- Detonation plan (/DFS/DETPLAN)

Input Files

Modeling Video

Model Description

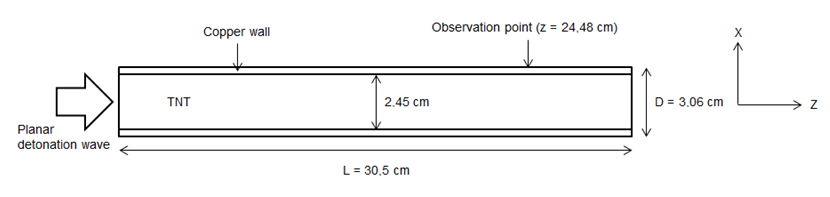

A OFHC copper cylinder (1.53cm diameter, 0.26cm thickness, 30.5cm height) is filled with an explosive (TNT). Detonation is initiated at the bottom of the explosive. Radial expansion is measured at a length of 8*D cm. With an Euler formulation, the air has to be modeled to measure radial expansion.

Figure 2. Problem description for cylinder test

Units: cm, s, g, Mbar

- Material Properties

- Value

- Rho_Initial

- 8.96 (g/cm3)

- Young's modulus

- 0.4229 (Pa)

- Poisson coefficient

- 0.33

- Yield stress

- 0.0009 (µBar)

- Hardening parameter

- 0.00292 (µBar)

- Hardening exponent

- 0.31

- Strain rate coefficient

- 0.025

- Reference strain rate

- 1e-06

- Specific heat per volume

- 1e+20

- EoS_Options_Input (Polynomial)

-

- C0 1e-06 (µBar)

- C1 = 1.38 (µBar)

- C2 = 1.372 (µBar)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 10 4

/MAT/LAW51/10

LAW_51_Copper

# Iform

12

# NU Nu_Vol

# MatID ALPHA_MAT

1 1.0

# MatID ALPHA_MAT

1 0.0

# MatID ALPHA_MAT

3 0.0

# MatID ALPHA_MAT

2 0.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Material Properties

- Value

- Rho_initial

- 1.63 (g/cm3)

- A parameter EoS

- 3.712 (µBar)

- B parameter EoS

- 0.0323 (µBar)

- R1 parameter EoS

- 4.15

- R2 parameter EoS

- 0.95

- Omega parameter EoS

- 0.3

- Detonation velocity

- 0.693

- Chapman Jouguet pressure

- 0.21 (µBar)

- Detonation Energy per Unit Volume

- 0.07

- Initial pressure

- 1e-06

- Unreacted explosive bulk modulus

- 0.036

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 11 4

/MAT/LAW51/11

LAW_51_TNT

# Iform

12

# NU Nu_Vol

# MatID ALPHA_MAT

1 0.0

# MatID ALPHA_MAT

1 0.0

# MatID ALPHA_MAT

3 0.0

# MatID ALPHA_MAT

2 1.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Material Properties

- Value

- Rho_Initial

- 0.0012 (g/cm3)

- EoS_options_Input (IDEAL_GAS)

-

- Heat Capacity Ratio = 1.4

- Initial Pressure = 1e-06 (µBar)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 12 4

/MAT/LAW51/12

LAW_51_Air

# Iform

12

# NU Nu_Vol

# MatID ALPHA_MAT

1 0.0

# MatID ALPHA_MAT

1 0.0

# MatID ALPHA_MAT

3 1.0

# MatID ALPHA_MAT

2 0.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Using the Multi-Material Solid, Liquid, and Gas material law (/MAT/LAW51), the Boundary material has the following characteristics.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

##HWCOLOR materials 4 6

/MAT/LAW51/4

NRF

# Iform

6

# Pext Tcp Tc_alpha

# ALPHA_1 RHO_01 E_01 P_min1 P_01

0.0 0.0 0.0 0.0 0.0

# SSP_01

0.0

# BLANK CARD

# ALPHA_1 RHO_01 E_01 P_min1 P_01

0.0 0.0 0.0 0.0 0.0

# SSP_01

0.0

# BLANK CARD

# ALPHA_1 RHO_01 E_01 P_min1 P_01

0.0 0.0 0.0 0.0 0.0

# SSP_01

0.0

# BLANK CARD

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Model Method

A 3D mesh is made of brick elements. The element size for the copper cylinder is approximately 0.035 cm x 0.035 cm x 0.035 cm.

The mesh is dragged along the z direction (z = 30.5 cm). It is important to have no discontinuity in element volume to ensure a good propagation of detonation wave and shock wave.

Units: cm, s, g, Mbar

Figure 3. Boundary condition

A planar detonation wave is defined at the bottom of the cylinder. A scale factor of 0.5 (on time step for all elements) is used for this type of application.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# q_a q_b h LAMBDA_V MU_V

# dt_min istrain IHKT

##HWCOLOR properties 1 3

/PROP/SOLID/1

ALE_PROP

# Isolid Ismstr Iale Icpre Itetra10 Inpts Itetra4 Iframe Dn

0 0 2 0

# qa qb h Lambda Mu

1.1 0.05 0.0 0.0

# deltaT_min

0.0Results

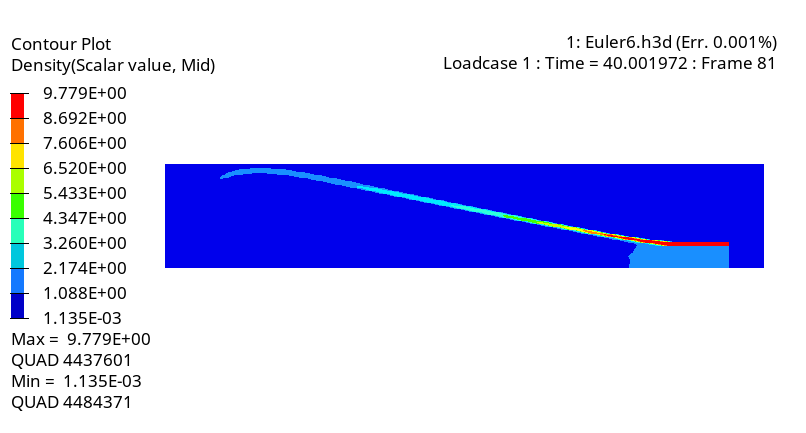

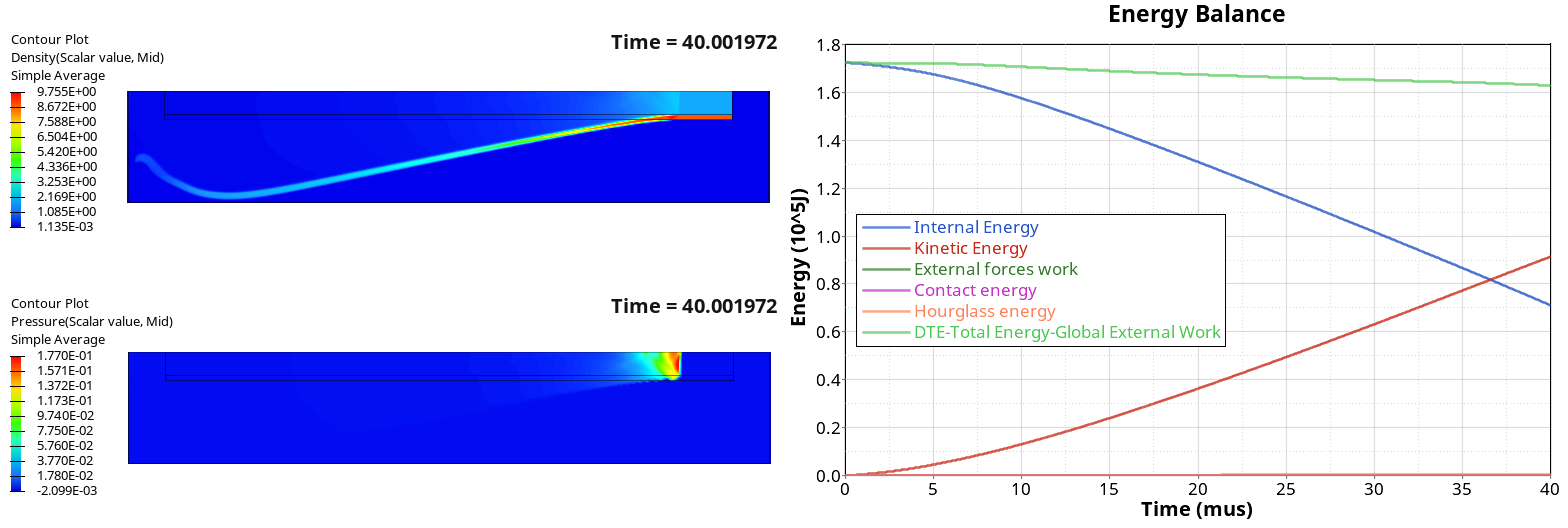

Figure 4. Density and pressure distributed in copper and TNT at time = 40µs. Energy balance is also displayed.

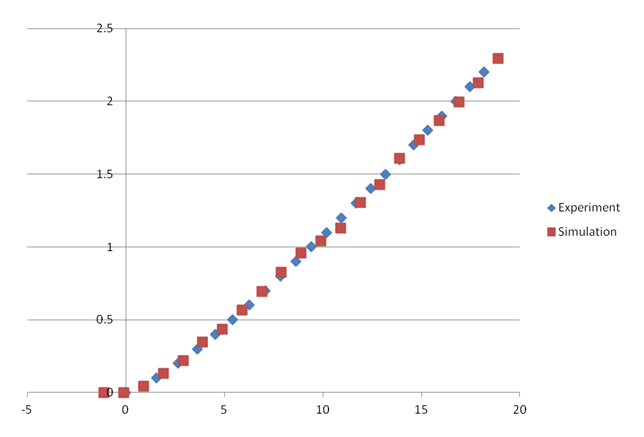

Figure 5. Comparison between experimental results and simulation results

Conclusion

Good correlation between experimental and simulation results. A thinner meshing could improve the correlation between simulation and experimental curves.