Drill Scan

Check the non-standard size of a drill hole.

- Target Objects Definition: Set the target object for analysis. Among the

following objects, select all necessary target objects.

- Via Hole Size

- DIP Type Pin’s Hole Size

- Board Figure Hole Size

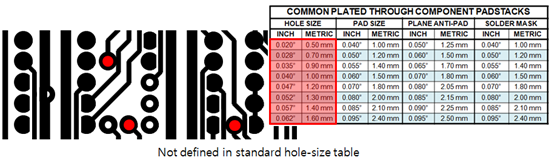

- Size Difference Checking: Depending on manufacturers, there may be different

standard drill hole sizes. Make the table for standard hole size using the

following table menu.

Figure 1.- Item: Specify the item name.

- Scan Range: Set target hole size value ranges.

- Base Value: Among the holes that have sizes in the scan range, PollEx DFM checks the size of the hole and if their values are not matching with the base value, they will be detected as fails.

- Check the difference between the smallest and largest Via hole diameter:

Check the difference between the largest via hole and the smallest via hole

among vias used in PCB design.

- Scan range of Via hole diameter: Designates the range of via hole size to be checked, if the option is not selected, all vias in the PCB design are subject to checking

- Maximum Via hole diameter difference: Specifies the diameter difference between the maximum allowable via hole and the minimum via hole diameter.

- Check the missing hole (for PTH): Check for missing holes on the Via and Dip

Pad.

- Tolerance between Top and Bottom Pad center: Set and check the tolerance value based on the centers of the Top and Bottom Pads. Only within the tolerance value is considered for checking