The Hysteretic Spring contact model allows plastic deformation behaviors to be

included in the contact mechanics equations, resulting in particles behaving in an elastic

manner up to a predefined stress.

Once this stress is exceeded, the particles behave as though undergoing plastic

deformation. The result is that large overlaps are achievable without excessive

forces acting upon them, thus representing a compressible material. Hysteretic

Spring normal force calculation is based on the Walton-Braun theory described in the

works of Walton and Braun (Walton and Braun

1986), (Walton and Braun 1986).

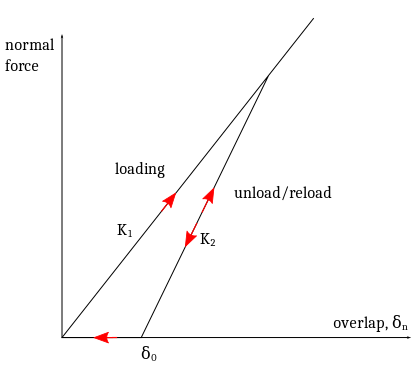

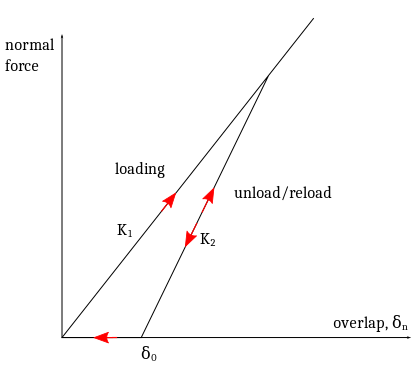

The following figure describes the Hysteretic Spring contact model force displacement

relationship.

Note: The unloading force goes to

zero before the displacement recovers to the initial contacting

point.

The quantity δ0 represents the residual ‘overlap’ that remains because of

the plastic deformation - flattening in the contact region. The exact location of

each old contact spot is not ‘remembered,’ so that particles become like new

undeformed spheres once they separate. Subsequent contacts will load along a new

loading path with slope, K1. Any reloading before separation follows the

slope K2 until the original loading curve K1 is reached, whereupon the

lower slope is followed until unloading occurs.

The normal force, FN, is defined as:

Where K1 and K2 are the loading and unloading stiffness

respectively, δn, is the normal overlap and δ0 is the residual

overlap. Loading stiffness, K1, is related to the yield strength of each

material participating in contact, Y1 and Y2, as follows

(Walton O.,

2006) in:

Here, R* is the equivalent radius of the two particles participating in

the contact. The Coefficient of Restitution is defined as:

This allows for the determination of K>2 from K1 (Walton O. ,

2006). Residual overlap is updated every Time Step according to the

following rule:

The main energy dissipation mechanism is due to the difference in spring stiffness

between loading and unloading phases. The need for an additional velocity dependent

dissipation mechanism, to suppress possible undamped low amplitude oscillations, was

suggested in (Walton O. , 2006). In EDEM's Hysteretic

Spring model, this mechanism was implemented in a way similar to the linear spring

normal damping force scaled by a dimensionless user set parameter Damping Factor,

bn, as follows:

Here k is either K1 or K2. The rest of the variables and

factors in the above expression are explained in the Linear Spring contact model

section.

Since the Hysteretic Spring model for normal force can be considered as an extension

of the Linear Spring model for normal force, it is recommended to use tangential

components of the Linear Spring model for tangential forces. In particular, a more

general form of the Linear Spring Elastic tangential force is used in the Hysteretic

Spring model in which the force depends on the user-defined stiffness factor,

γt, as follows:

As opposed to the normal component, the tangential damping force is not scaled by the

damping factor.

For particles, a default value for the Yield Strength is estimated from the Young’s

Modulus E and Radius of the particle R according to the algorithm suggested in

(Walton O. ,

2006). Initially, the possible default value is calculated as

follows:

If this value is less than 100Pa, it is replaced with a value of 0.003 *E.

For Geometries, the default value is set to 1e+09 Pa.