Product Introduction

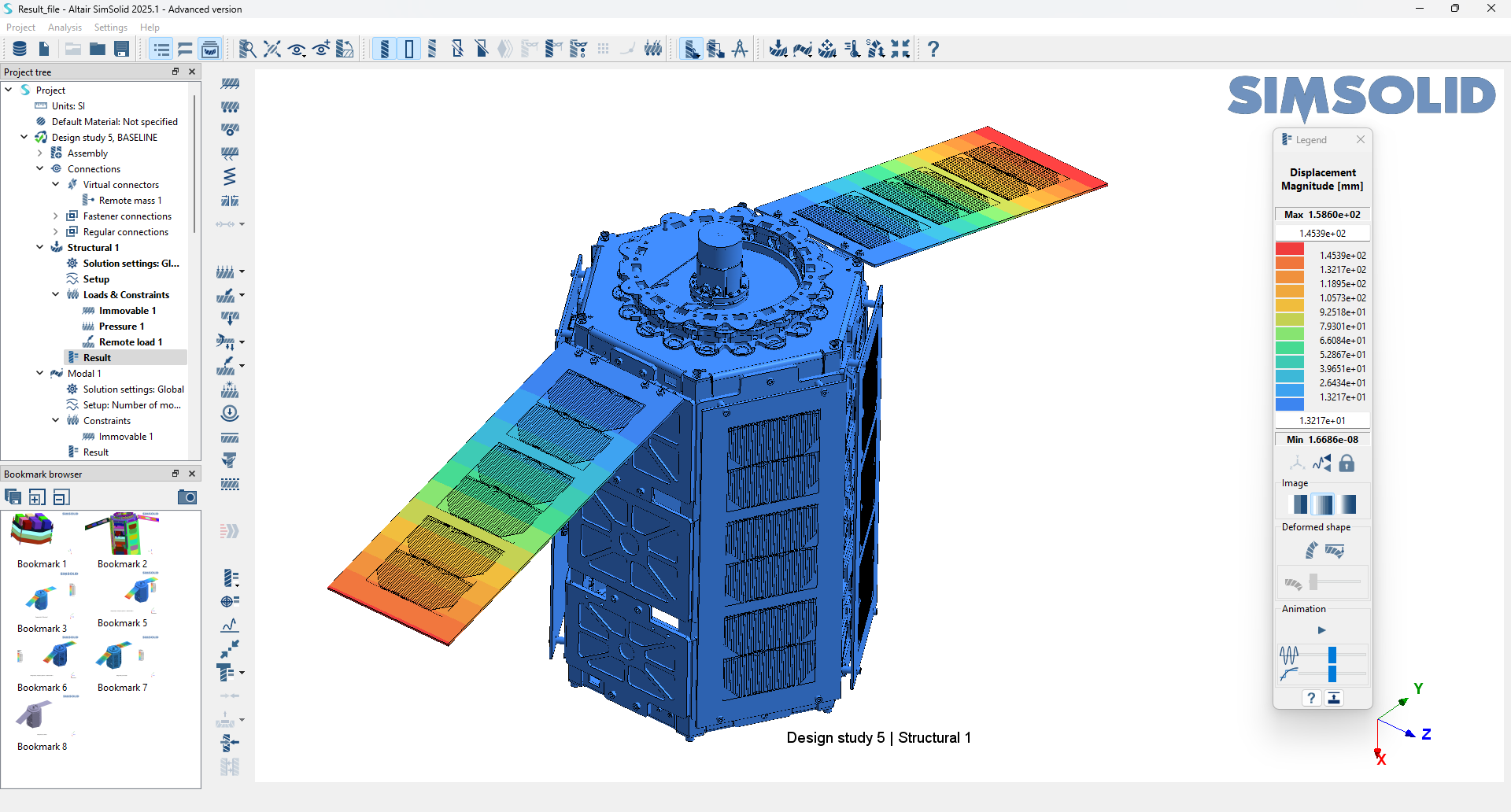

Altair SimSolid is a structural analysis software designed for rapid, early-stage design exploration by eliminating the need for geometry simplification and meshing common in traditional FEA. It utilizes a unique external approximations technology, allowing it to analyze full CAD assemblies with complex features in minutes on standard PCs. This speed enables quick iteration across a wide range of analysis types, from modal to nonlinear.

Technology

- Absolutely arbitrary geometrical shapes can be used as finite elements

- Basis functions which approximate field of interest in the part volume can be of arbitrary class and are independent of the volume shape

SimSolid does not use the point-wise degrees of freedom (DOF) inherent in traditional FEA. SimSolid's DOF are functional with geometrical support in the form of volumes, areas, line clouds, and point clouds. This provides the ability to handle geometrical imperfections, as well as assembly contact imperfections like gaps, penetrations and ragged contact areas.

This unique technological foundation provides the flexibility and robustness required to handle a wide range of engineering challenges, including advanced material behaviors and complex loading scenarios seen in modern designs.

SimSolid controls solution accuracy using multiple-pass adaptive analysis. Adaptivity can be defined on a global or part local basis and adaptivity is always active The methodology is fast and efficient. It provides superior performance metrics for computational time and memory footprint that allow very large and/or complex assemblies to be solved quickly on desktop class PCs.

More information on the technology used in SimSolid can be found in Theoretical Background.

Capabilities

SimSolid has the following capabilities:

- Analysis sequences - Modal, linear static, nonlinear static, linear buckling, frequency response, linear transient, random response, thermal, thermal-stress, inertia relief, linear superposition, composite analysis, fatigue, squeak and rattle.

- Material models - isotropic, rigid, orthotropic, user extensible.

- Connections - Auto-connections, bonded, sliding, separation with friction, bolts, spot welds, seam welds, bushings, rivets, virtual connectors, adhesives, joints.

- Results evaluation - Contours and animations of displacements, stresses, strains, strain energy and safety factors. Frequencies and mode shapes. Modal participation factors. XY plots. Reaction and contact forces, improved section cuts.

Benefits

- Analyze full assemblies - SimSolid has been developed from the ground up to be a large assembly solver. It is possible to analyze assemblies with 100s to 1000s of parts directly on a standard laptop or desktop computer.

- No geometry simplification or meshing - SimSolid eliminates geometry simplification and meshing, the two most time-consuming and expertise-extensive tasks done in traditional FEA. Full geometric details like small holes, fillets, bosses can be left in the model, significantly accelerating design iteration cycles.

- Multiple-pass adaptive solver provides automated solution accuracy - SimSolid uses multiple solution passes, local and global error analysis and adaptive local enrichment to ensure solution accuracy.

- Results obtained in seconds to minutes - SimSolid is fast, real fast. Solution times are typically measured in seconds to minutes. With SimSolid, multiple design scenarios can be quickly analyzed and compared, extending its rapid analysis capabilities to a wider spectrum of engineering problems, from linear static to advance nonlinear and composite simulations.

Product Verification

SimSolid has been extensively tested and verified. Go to the SimSolid Verification Problems to view solved models.