Particles

![]()

Description

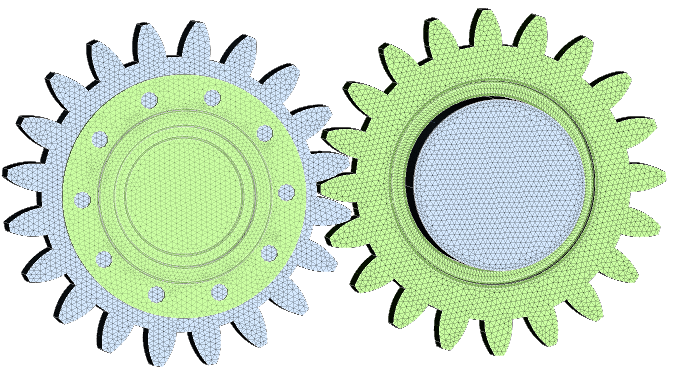

This option is used to generate a uniformly distributed particle for the nanoFluidX (nFX) solver. The particles form a grid in the global XYZ axis with one point at the origin. The output from this operation is a point mesh (point body). The SPH particles are the nodes.The input geometry can be CAD or FE models.

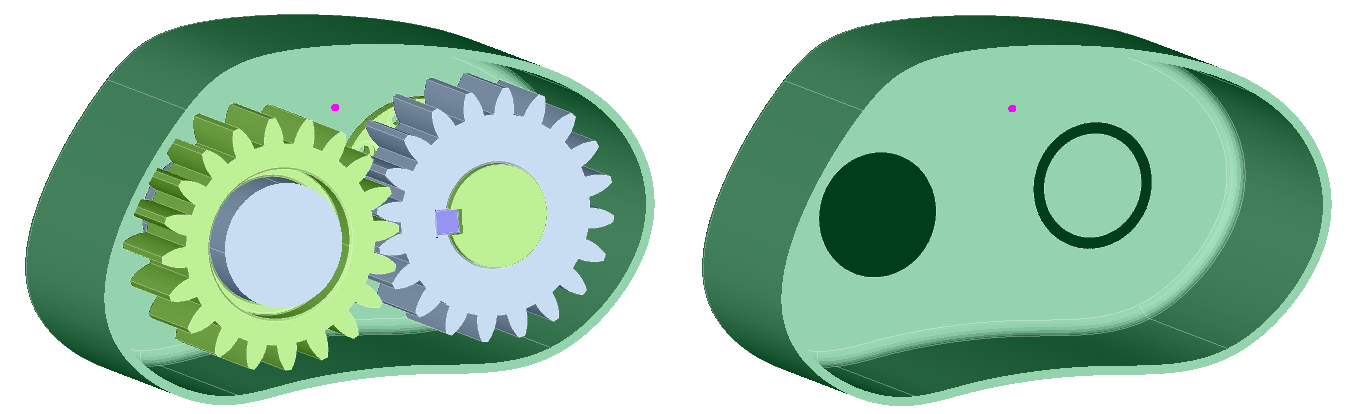

A model typically has solids that are stationary (outer container for example), solids that move (gears, shafts, etc.) and sometimes solids that represents the liquid and gas (fluids) inside the container. The stationary part is modelled as is or, to improve solver performance, the wetted surface is identified and a thick region is created. The moving parts are modelled as hollow solids. If the fluid regions are represented as solids then they are meshed as is. In the absence of solids for the fluid regions, the fluid region is defined by a node contained in the fluid region. The fluid - fluid interface (mostly liquid - gas interface) is defined by the plane/cuboids and the software automatically creates particles for both the fluid regions (liquid and gas).Free node inside fluid

This option helps to specify the fluid (liquid and gas) regions inside the container. This is useful when the CAD or FE model does not have a separate body for the fluids (liquid and gas). The fluid options are defined using initial boundary condition and based on the specified particle spacing value in "Solution browser tree | Particle Settings", particles for fluid region are created. Modifying these fluids are available under nFx Tools | Particle Creation | Create/Modify Particles . The Plus icon is used to create a node and its details are available under Create Node. It helps to define the free node inside the fluid.Moving solids

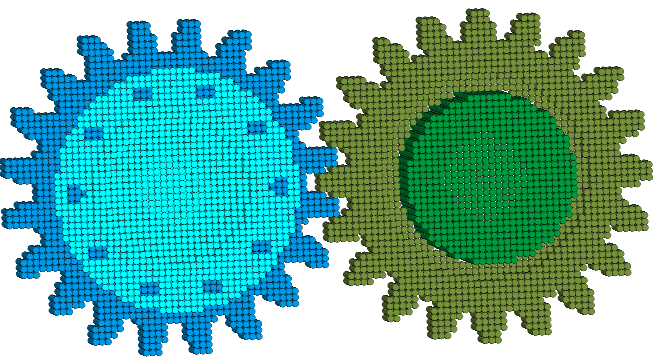

The bodies assigned with motion in active SPH Flow solution are automatically considered as moving solids and also user can manually select the bodies as moving solids, like gears, shafts, or casings which are solids. Particles will be created inside the solid region based on the specified particle spacing value in active SPH Flow solution. To reduce model size, users can model the solids as a thick solid (hollow inside) without impacting the results.

No of moving solid layers is used to specify a finite number of moving solid layers of particles needed from the solid surface.

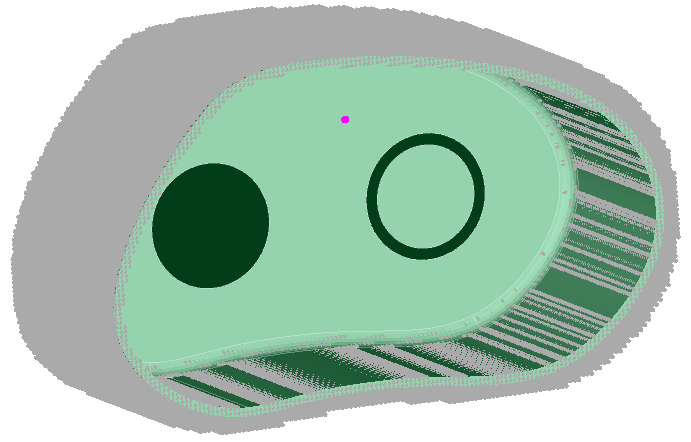

No of static solid layers is used to specify the finite number of static solid layers of particles created away from the wetted surface.

In the below model, the moving solids (gears/shaft) are modelled as solids. So, while creating particles for static solids (container), the Moving solids should be ignored. Hence the bodies that would be considered for creating static solids (container) is bodies from the active solution minus Moving solids.

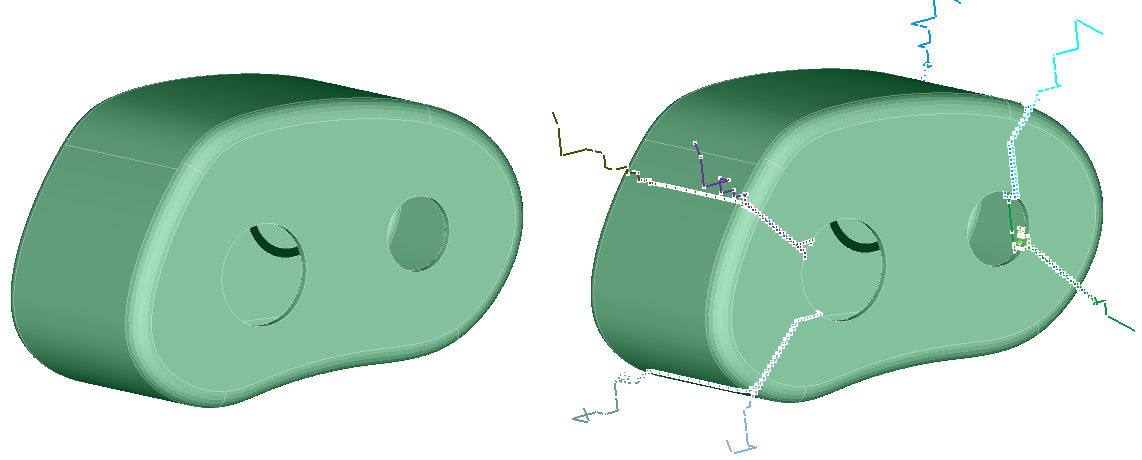

Automatic leak detection

When generating particle mesh for fluids (Liquid and Gas) and for static solids (Container), if any leaks are present, the leak paths will be displayed.

- If the Solution already contains the particle mesh for an input body, the particle mesh in the Solution would be replaced by the newly created particle body.

- Particles for the bodies in baffle boundary conditions are created along with the output particle bodies.

- Duplicate particles are automatically identified and baffle particles are retained with high priority then moving solid particles then static solids and then fluids.

- Three layers of missed out particles between fluids and solids/baffles

interaction are created for the following use cases

- On creating fluids, solids/baffles and all bodies are considered as moving solids

- On creating fluids, solids/baffles and container.

- Particles for the specified custom faces in probes boundary conditions and for the specified regions/custom faces in inlet boundary conditions are created in the separate model named as "InletRegionsProbes.gda" and these particles will not be aligned with the global XYZ grid. By default, these particles are created with tolerance of 5 percent of particle spacing value. Supported an environmental variable “SIMLAB_PROBES_PARTICLE_TOL” to set a value from 0 to 1 and it represent tolerance as 0 to 100 percent of particle spacing value.

- The faces specified in the "Inlet | Custom | Select faces" and “Probes | Massflow probe | Custom surface” are ignored in particle creation.

- In Tank Sloshing solution, motion bodies are not automatically considered as moving solids and moving solids particle creation is optional.