TCP Bonding Mark

Check the rule of TCP bonding mark design.

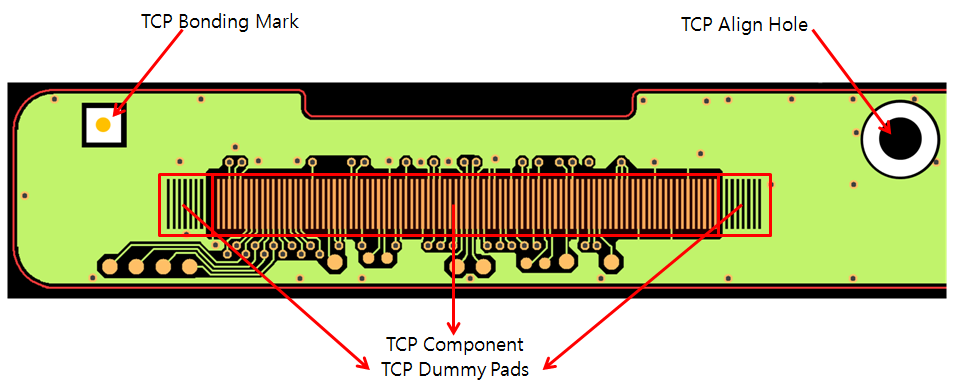

The TCP component is a tape carrier package. The TCP bonding mark is constructed with solder mask and pad shape. Placed at the edge of the TCP component, the TCP bonding mark is used to identify the TCP component.

Figure 1.

- TCP Component Definition: Define the TCP components.

- Component Selection: If components are registered as a group, select them from list.

- Minimum Pin Count Limit: Using this option, among components group, you can choose target components which have more pins than the given value.

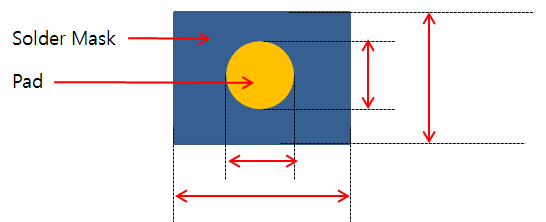

- TCP Bonding Mark Definition: Define TCP bonding marks.

- Component Selection: If TCP bonding marks are registered as a component, select them from component group list.

- Board Figure: If TCP bonding marks are designed with board figure

geometries, specify their mark size and pad size.

- Mark Size: Set the mark size X and Y.

- Pad Size: Set the pad size X and Y.

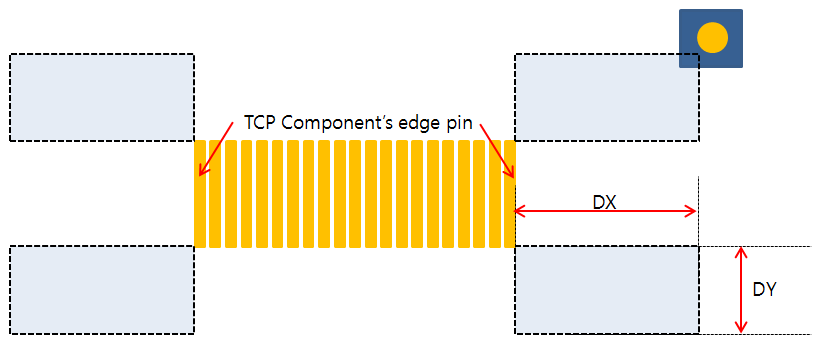

- Mark Searching Area from Component’s Pin Edge: TCP bonding mark

should be placed near the TCP component. To define TCP bonding mark

finding area from TCP component edge pad, set DX and DY value.

- Checking

- Placement: Check the TCP bonding mark placed layer.

- TCP Component Layer: When this option is checked, TCP bonding mark should be placed at the same layer with TCP components or it is a fail.

- Top: Under this option, all TCP bonding marks should be placed on the top.

- Bottom: Under this option, all TCP bonding marks should be placed on the bottom.

- Check Difference between Two-sides Mark Shape: If this option is

checked, PollEx DFM checks the shape of

side TCP bonding mark. If the shape is different, it is fail.

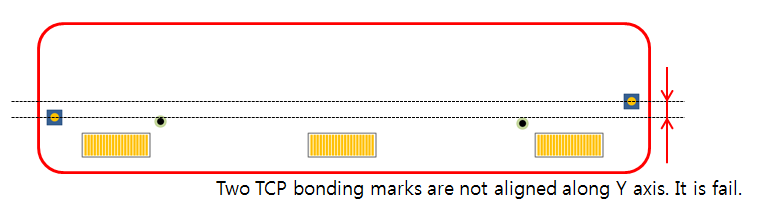

Figure 2. - TCP Bonding Marks’ Counting: To check the number of TCP bonding mark on design, set the value and select maximum/minimum/matching condition.

- Arrangement for Y Location: Check side edge’s TCP bonding mark

alignments along Y-axis.

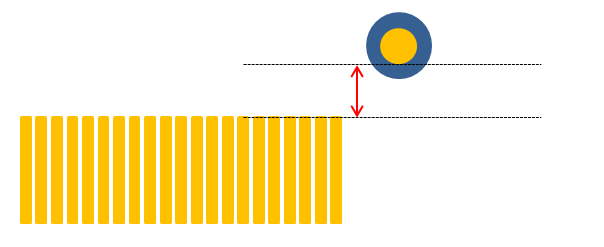

Figure 3. - Y Axis Clearance between TCP Component and TCP Mark Pad’s Edge: Set

the Y-axis clearance value between TCP component and TCP bonding

mark pad edge.

Figure 4.- Tolerance: If Y-axis values differences are within tolerance, PollEx DFM defines them as the same value.

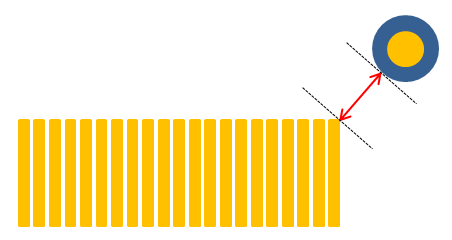

- Clearance between TCP Mark and Components: Set the clearance value

between TCP bonding mark and TCP component.

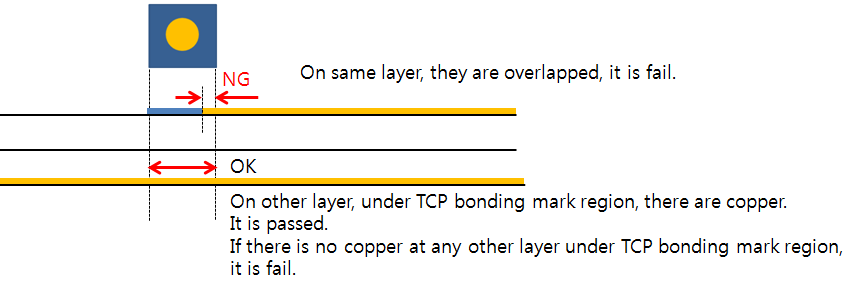

Figure 5. - Copper Existence: Check TCP bonding marks are overlapped with

copper-pour on the same layer and copper-pour existence under TCP

bonding mark region on other layer.

Figure 6. - Silkscreen Overlapping: Checks TCP bonding marks overlapping with

silkscreen data.

- Gerber: To get silkscreen screen, use GERBER file data. Use

this option after reading GERBER file for top and bottom.

- Top: Select GERBER top layer from layer list.

- Bottom: Select GERBER bottom layer from layer list.

- Gerber: To get silkscreen screen, use GERBER file data. Use

this option after reading GERBER file for top and bottom.

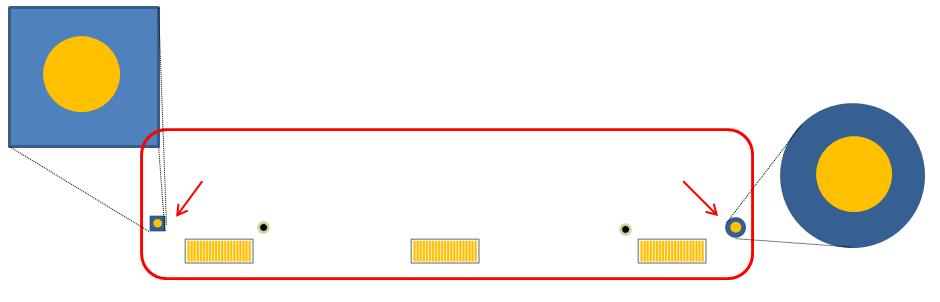

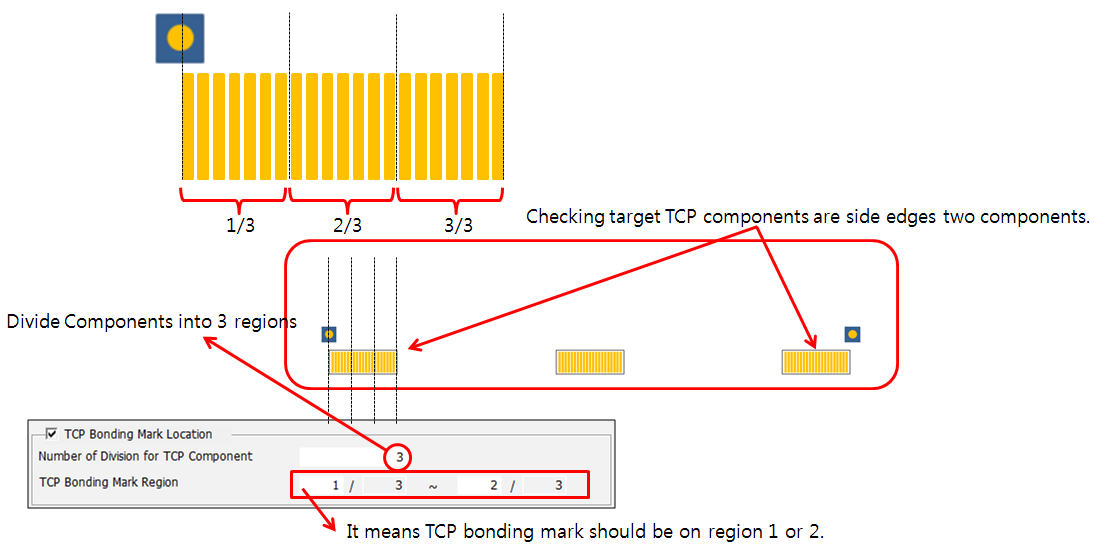

- TCP Bonding Mark Location: Check the TCP bonding marks location for

TCP components at edge of board.

Figure 7.- Number of Division for TCP Component: Set value to divide component region.

- TCP Bonding Mark Region: Set region on which TCP bonding marks should be placed.

- Placement: Check the TCP bonding mark placed layer.