TCP Align Hole

Check the rule of align hole usage.

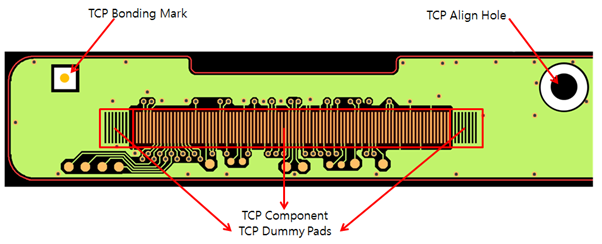

TCP component is a tape carrier package. TCP align hole is used to fix the TCP components.

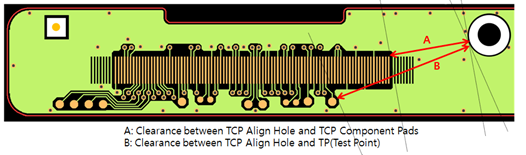

Figure 1.

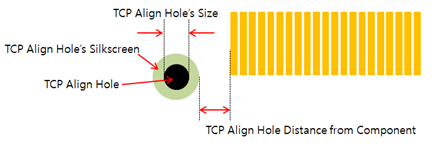

- TCP Align Hole Definition: TCP align hole can be defined with the hole size

and distance from the TCP component.

Figure 2.- Definition with Hole Size: Define the align hole with its size. Using the floating value input tool, set the size or range of hole size.

- Define with Distance from TCP Component Group: TCP align hole should

not be apart from the TCP component. They should be placed close

together.

Figure 3.- Component Group: Select the TCP component group from the component group list.

- Maximum Distance: Set the maximum distance between the TCP component and the TCP align hole.

- Silk Hole Mark Definition: TCP align hole can have two types of shapes for

silkscreens: circle and line types. Define the diameter and width/height

value for the circle and line types.

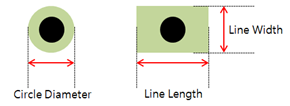

Figure 4.- Circle Diameter: Set the circle diameter for the circle type silkscreen.

- Line: Set the line type silkscreen with its width and length.

- Width: Set the width of line for line type silkscreen.

- Length: Set the length of line for line type silkscreen.

- TP(Test Point) Definition: To check the clearance between a TCP align hole

and a test point, set the test point components.

- TP Component Group Selection: If test points are registered with footprint, select the test point component group from the component group list.

- Pads’ Diameter in Routing: If test points are used with pads, set the size of the pad diameter.

- Via’s Diameter: If test points are used with vias, set the size of the via diameter.

- TCP Align Hole Clearance Checking: Check clearances between the TCP align

hole and the TCP component pad/test points in the design.

Figure 5.- Clearance between TCP Align Hole and TCP Pads: Set the clearance value between the TCP align hole and the TCP component pads.

- Clearance between TCP Align Hole and TP (Test Point): Set the clearance value between the TCP align hole and the test points.

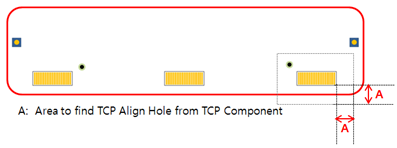

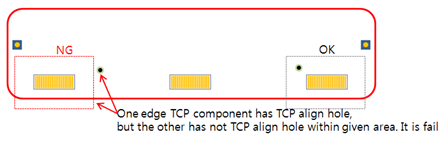

- TCP Align Hole Checking: Check TCP align hole location and placement.

- Existence Check for both Edge Components: Check if all edge TCP

components have a TCP align hole within the given area. Hole

searching area is defined in the TCP Align Hole Definition. If one

of them doesn’t have a TCP align hole, it is a fail.

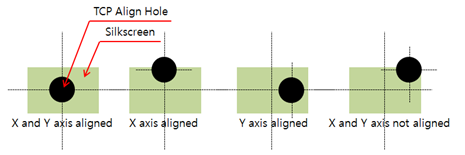

Figure 6. - Silk Hole Mark Alignment with TCP Align Hole: Check if the TCP align

hole and silkscreen are aligned along the given axis.

Figure 7.- X: Check if the TCP align hole is aligned with silkscreen along the X-axis. If they are not aligned along the X-axis, it is a fail.

- Y: Check if the TCP align hole is aligned with silkscreen along the Y-axis. If they are not aligned along the Y-axis, it is a fail.

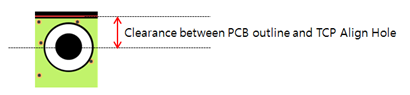

- Clearance between PCB Outline to TCP Align Hole Center: Set the

clearance value between the TCP align hole and the PCB outline.

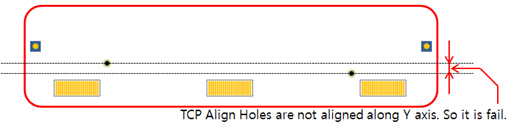

Figure 8. - Alignment between Side Edge TCP Align Holes: Check if the side

edge’s TCP align holes are aligned with each other along the

Y-xis.

Figure 9.- Tolerance: For the two location values, if they are less than the tolerance, PollEx DFM recognizes them as the same value.

- X/Y: Select alignment axis.

- Number of TCP Align Holes’ Counting: Check the number of TCP align holes in the design. Choose the maximum/minimum/same value counting condition.

- Existence Check for both Edge Components: Check if all edge TCP

components have a TCP align hole within the given area. Hole

searching area is defined in the TCP Align Hole Definition. If one

of them doesn’t have a TCP align hole, it is a fail.