HS-1506: Material Calibration with a Curve Difference Integral

In this tutorial, you will learn how to register a Compose, Python, or Templex function in HyperStudy.

The .py and .oml file contain a function that calculates the area between two curves.

The objective of this tutorial is to find the Radioss material parameter values so that the stress-strain curve of the tensile test simulation matches the tensile test experimental curve.

HS-1507: Material Calibration with Area Tool in Data Source provides an alternative method to set up this problem using the Area tool.

HS-4200: Material Calibration Using System Identification provides an alternative method to set up this problem using system identification.

- Create an input template from a Radioss file using the HyperStudy - Editor

- Register a Compose, Python, or Templex function

- Set up a study

- Run a system identification optimization study

Model Definition

A quarter of a standard tensile test specimen is modeled using symmetry conditions. A traction is applied to a specimen via an imposed velocity at the left-end.

- Stress level

- Plastic strain

- Yield Stress

- Hardening modulus

- Hardening exponent

- Strain rate coefficient

- Strain rate

- Reference strain rate

Create Base Input Template

In this step, you can create the base input template in HyperStudy or use the base input template in the study Directory.

- Start HyperStudy.

-

From the menu bar, click .

The Editor opens.

- In the File field, open the TENSILE_TEST_0000.rad file.

-

In the Find area, enter /MAT/PLAS_JOHNS/1 and click

.

HyperStudy highlights /MAT/PLAS_JOHNS/1.

.

HyperStudy highlights /MAT/PLAS_JOHNS/1.Figure 5.

-

Select variable E by highlighting the first 20 fields in row 51.

Tip: Quickly highlight 20-character fields by pressing Ctrl to activate the Selector (set to 20 characters) and then clicking the value.

Figure 6.

- Right-click on the highlighted fields and select Create Parameter from the context menu.

-

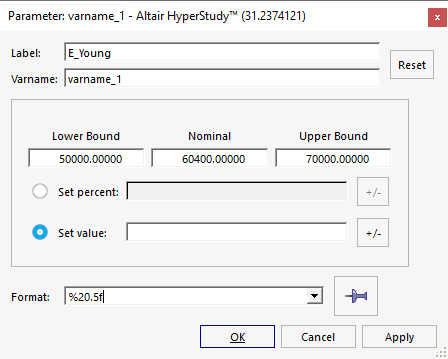

In the Parameter: varname_1 dialog, define the following

options and click OK.

- In the Label field, enter E_Young.

- Change the Lower Bound to 50000.

- Change the Nominal value to 60400.

- Change the Upper Bound to 70000.

- Change the Format to %20.5f.

Figure 7.

-

Define four more variables using the information provided in Table 1.

Table 1. Variable Label Lower Bound Nominal Upper Bound Format a a_PlasticityYieldStress 90 110 120 %20.5f b b_HardeningCoeff 100 125 160 %20.5f n n_HardeningExpo 0.1 0.2 0.3 %20.5f sigmax Sigma_Max 250 280 290 %20.5f - Click Save.

- In the Save Template dialog, save the file as TENSILE_TEST_0000.tpl.

- Close the Editor.

Register Curve Difference Function

In this step you will register the curve difference function using Compose/OML, Python, or Templex.

The function curve_difference calculates the integral of the

absolute value of the difference between two curves over the common domain of the

supplied functions. This is a robust function that tends to zero only as the two

functions become equal.

-

Register the

curve_differencefunction using Compose.- Start Compose.

- From the menu bar, click .

- In the Open File dialog, open the file Curve_Difference.oml.

-

Highlight the function

curve_difference(...). - Right-click on the highlighted text and select Register Function from the context menu.

- In the Register Function dialog, click OK.

- Close Compose.

-

Register the

curve_differencefunction using Python. -

Register the

curve_differencefunction using Templex.- From the menu bar, click .

- In the HyperStudy - Set Preference File dialog, open the curve_difference.mvw file.

Perform the Study Setup

-

Start a new study in the following ways:

- From the menu bar, click .

- On the ribbon, click

.

.

- In the Add Study dialog, enter a study name, select a location for the study, and click OK.

- Go to the Define Models step.

-

Add a Parameterized File model.

-

Define a model dependency.

- Click Model Resources.

- In the Model Resource dialog, select Model 1 (m_1).

- Click .

- In the Select File dialog, navigate to your working directory and open the TENSILE_TEST_0001.rad file.

- Set Operation to Copy.

- Click Close.

Figure 9.

-

Click Import Variables.

Five input variables are imported from the TENSILE_TEST_0000.tpl resource file.

- Go to the Define Input Variables step.

- Review the input variable's lower and upper bound ranges.

Perform Nominal Run

- Go to the Test Models step.

-

Click Run Definition.

An approaches/setup_1-def/ directory is created inside the study Directory. The approaches/setup_1-def/run__00001/m_1 directory contains the input file, which is the result of the nominal run.

Create and Evaluate Output Responses

In this step, you will use the curve_difference function to create

and evaluate output responses.

In order to fit the RADIOSS stress-strain curve to the experimental data, you must compare the two curves.

-

Create the Area Between Two Curves output response.

- Go to the step.

- Click Add Output Response.

- In the work area, Label field, enter Area Between Two Curves.

Figure 10.

-

Create a data source labeled Disp_sim.

-

Create a second data source labeled Force_sim by

repeating step 2.

Define the following options:

- Set Type to Section/SECTION_2.

- Set Request to 2 section 1.

- Set Component to FT-Resultant Tangent Force.

-

Create a third data source labeled Strain_exp.

-

Create a fourth file source labeled Stress_exp by

repeating step 4.

Select the following options:

- Set Type to Unknown.

- Set Request to Block1.

- Set Component to Column 2.

-

Define the Area Between Two Curves output response.

- Click OK to close the Expression Builder.

- Click Evaluate to extract the response values.

Run Optimization

-

Add an Optimization.

- In the Explorer, right-click and select Add from the context menu.

- In the Add dialog, select Optimization.

- For Definition from, select Setup and click OK.

- Go to the step.

- Click the Objectives/Constraints - Goals tab.

-

Apply an objective on the Area Between Two Curves output response.

- Click Add Goal.

- In the Type column, select Minimize.

Figure 15.

- Go to the step.

-

In the work area, set the Mode to Adaptive

Response Surface Method (ARSM).

Note: Only the methods that are valid for the problem formulation are enabled.

- Click Apply.

- Go to the Evaluate step.

- Click Evaluate Tasks.

-

Click the Evaluation Plot tab to plot the optimization

iteration history of the objective.

Figure 16.