HS-4200: Material Calibration Using System Identification

Learn a method for characterizing parameters of a RADIOSS material law used for modeling elasto-plastic material.

The characterization of a ductile aluminum alloy is studied. A RADIOSS simulation is performed to replicate an experimental tensile test. The parameters of the material law are determined to fit the experimental results.

HS-1506: Material Calibration with a Curve Difference Integral provides an alternative method to setup this problem using a HyperMath or Python function to measure the difference between two curves.

HS-1507: Material Calibration with Area Tool in Data Source provides an alternative method to set up this problem using the Area tool.

Model Definition

A quarter of a standard tensile test specimen is modeled using symmetry conditions. A traction is applied to a specimen via an imposed velocity at the left-end.

- Stress level

- Plastic strain

- Yield Stress

- Hardening modulus

- Hardening exponent

- Strain rate coefficient

- Strain rate

- Reference strain rate

Create Base Input Template

In this step, create the base input template in HyperStudy or use the base input template in the study directory.

- Start HyperStudy.

-

From the menu bar, click .

The Editor opens.

-

In the File field, navigate to your working directory and open the file

TENSILE_TEST_0000.rad.

Note: RADIOSS uses fixed fields of 20 characters for properties.

-

In the Find area, enter /MAT/PLAS_JOHNS/1 and click

.

HyperStudy highlights /MAT/PLAS_JOHNS/1 in the TENSILE_TEST_0000.rad file.

.

HyperStudy highlights /MAT/PLAS_JOHNS/1 in the TENSILE_TEST_0000.rad file.Figure 5.

-

Select E by starting at the beginning of row 51 and

highlighting the first 20 fields.

Tip: To assist you in selecting 20-character fields, press Control to activate the Selector (set to 20 characters) and then click the value.

Figure 6.

-

Right-click on the highlighted fields and select Create

Parameter from the context menu.

The Parameter: varname_1 dialog opens.

- In the Label field, enter E_Young.

-

Change the bounds.

- Lower Bound: 50000

- Nominal: 60400

- Upper Bound: 70000

- In the Format field, enter %20.5f.

-

Click OK.

Figure 7.

-

Define four more variables using the information provided in Table 1.

Note: Some of the initial values are different from the values in the original file.

Table 1. Variable Label Lower Bound Nominal Upper Bound Format a a_PlasticityYieldStress 90 110 120 %20.5f b b_HardeningCoeff 100 125 160 %20.5f n n_HardeningExpo 0.1 0.2 0.3 %20.5f sigmax Sigma_Max 250 280 290 %20.5f - Click OK to close the Editor.

- In the Save Template dialog, navigate to your working directory and save the file as TENSILE_TEST_000.tpl.

Perform the Study Setup

-

Start a new study in the following ways:

- From the menu bar, click .

- On the ribbon, click

.

.

- In the Add Study dialog, enter a study name, select a location for the study, and click OK.

- Go to the Define Models step.

-

Add a Parameterized File model.

-

Define a model dependency

Figure 9.

-

Click Import Variables.

Five input variables are imported from the TENSILE_TEST_0000.tpl resource file.

- Go to the Define Input Variables step.

- Review the input variable's lower and upper bound ranges.

Perform Nominal Run

- Go to the Test Models step.

-

Click Run Definition.

An approaches/setup_1-def/ directory is created inside the study directory. The approaches/setup_1-def/run__00001/m_1 directory contains the input file, which is the result of the nominal run.

Create and Evaluate Output Responses

In this step, you will compare RADIOSS stress-strain curve to the experimental data.

- Difference between experimental stress and RADIOSS at Strain equal 0.02 (1)

- Difference between experimental strain and RADIOSS at Necking point (2)

- Difference between experimental stress and RADIOSS at Necking point (3)

- Go to the Define Output Responses step.

-

Create a data source labeled Disp_sim.

-

Repeat step 2 to

create a second data source labeled Force_sim, making the

following changes during the process:

- Set Type to Section/SECTION_2.

- Set Request to 2 section 1.

- Set Component to FT-Resultant Tangent Force.

-

Create three output responses.

-

Define the Radioss_Strain_0_2 output response.

-

Define the Radioss_Stress_Necking output response.

-

Define the Radioss_Strain_Necking output response.

- Click Evaluate to extract the response values.

Run Optimization

-

Add an Optimization.

- In the Explorer, right-click and select Add from the context menu.

- In the Add dialog, select Optimization.

- For Definition from, select Setup and click OK.

- Go to the step.

- Click the Objectives/Constraints - Goals tab.

-

Add an objective.

- Click Add Goal.

- In the Apply On column, select Radioss_Strain_0_2.

- In the Type column, select More.

- In column 1, select System Identification.

- In column 2, enter 141.00000.

Figure 16. -

Apply an objective on the Radioss_Stress_Necking and Radioss_Strain_Necking

output responses.

- Go to the step.

-

In the work area, set the Mode to Adaptive

Response Surface Method (ARSM).

Note: Only the methods that are valid for the problem formulation are enabled.

- Click Apply.

- Go to the step.

- Click Evaluate Tasks to launch the optimization.

-

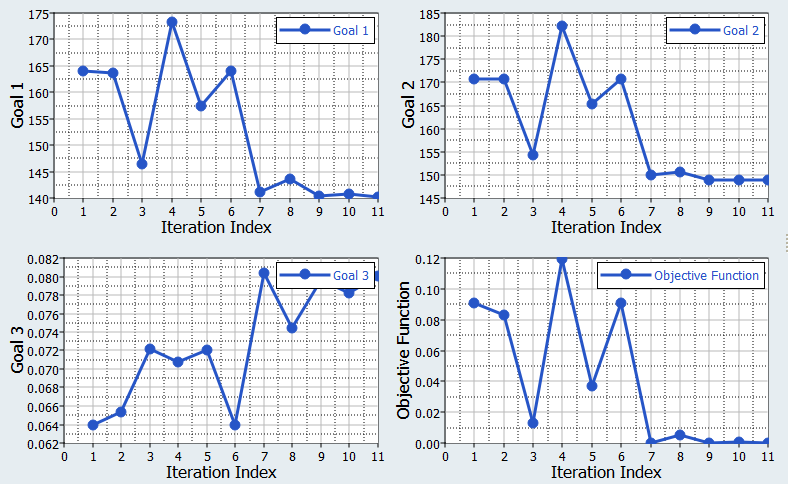

Review iteration history.