/INTER/TYPE7

Block Format Keyword Interface TYPE7 is a multi-usage impact interface, modeling contact between a main surface and a group of secondary nodes. It is also possible to consider heat transfer and heat friction.

Description

- A node can at the same time be a secondary and a main node.

- Each secondary node can impact each main segment; except if it is connected to this segment.

- A node can impact on more than one segment.

- A node can impact on the two sides, on the edges and on the corners of each segments.

- It is a fast search algorithm without limitations.

- Time step is reduced in case of high impact speed or contacts with small gap.

- It does not work properly if used with a rigid body at high impact speed or rigid body with small gap.

- It does not solve edge to edge contact (to solve this, /INTER/TYPE11 should be used along with TYPE7).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /INTER/TYPE7/inter_ID/unit_ID | |||||||||

| inter_title | |||||||||

| grnd_IDs | surf_IDm | Istf | Ithe | Igap | Ibag | Idel | Icurv | Iadm | |

| Fscalegap | Gapmax | Fpenmax | ITIED | ||||||

| Stmin | Stmax | %mesh_size | dtmin | Irem_gap | Irem_i2 | ||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| node_ID1 | node_ID2 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Stfac | Fric | Gapmin | Tstart | Tstop | |||||

| IBC | Inacti | VISs | VISF | Bumult | |||||

| Ifric | Ifiltr | Xfreq | Iform | sens_ID | fct_IDF | AscaleF | fric_ID | ||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| C6 | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| NRadm | Padm | Angladm | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Kthe | fct_IDK | Tint | Ithe_form | AscaleK | |||||

| Frad | Drad | Fheats | Fheatm | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| inter_ID | Interface identifier. (Integer, maximum 10 digits) |

|

| unit_ID | unit_ID. (Integer, maximum 10 digits) |

|

| inter_title | Interface title. (Character, maximum 100 characters) |

|

| grnd_IDs | Secondary nodes group

identifier. (Integer) |

|

| surf_IDm | Main surface

identifier. (Integer) |

|

| Istf | Interface stiffness definition flag.

3

For SPH, only Istf=0,

1 and 1000 are available.

(Integer) |

|

| Ithe | Heat contact flag.

(Integer) |

|

| Igap | Gap/element option flag. 11

(Integer) |

|

| Ibag | Airbag vent holes closure flag in case

of contact. This flag is also used to activate Sol2SPH particles, if the

corresponding solid element is in contact.

(Integer) |

|

| Idel | Node and segment deletion flag.

(Integer) Note: Idel = 1 and

-1 has a higher CPU cost when compared with Idel = 2 and

-2.

|

|

| Icurv | Gap envelope with curvature. 5

(Integer) |

|

| Iadm | Computing local curvature flag for

adaptive meshing. 6

7

8

(Integer) |

|

| Fscalegap | Gap scale factor (used only when Igap = 2 and

3). Default = 1.0 (Real) |

|

| Gapmax | Maximum gap (used only when Igap = 2 and

3). (Real) |

|

| Fpenmax | Maximum fraction of initial penetration.

13 (Real) |

|

| ITIED | Tie contact nodes flag.

(Integer) |

|

| Stmin | Minimum stiffness (used only when Istf = 2,

3, 4, or

5). (Real) |

|

| Stmax | Maximum stiffness (used only when Istf = 2,

3, 4, or 5). Default = 1030 (Real) |

|

| %mesh_size | Percentage of mesh size (used only when

Igap = 3). Default = 0.4 (Real) |

|

| dtmin | Minimum interface time step. 23

(Real) |

|

| Irem_gap | Flag for deactivating secondary nodes if

element size < gap value, in case of self-impact contact. 14

(Integer) |

|

| Irem_i2 | Flag for deactivating the secondary

node, if the same contact pair (nodes) has been defined in interface TYPE2.

|

|

| node_ID1 | First node

identifier. (Integer) |

|

| node_ID2 | Second node identifier (ignored when Icurv = 1). (Integer) |

|

| Stfac | Stiffness scale factor applied to main

side of the interface (if Istf

1). Default = 1.0 (Real) |

|

| Interface stiffness (if Istf = 1). Default = 1.0 (Real) |

||

| Fric | Coulomb friction (if fct_IDF = 0). Default = 0.0 (Real) |

|

| Coulomb friction scale factor (if fct_IDF

0). 20 Default = 1.0 (Real) |

||

| Gapmin | Minimum gap for impact activation. For default values, see 10 (Real) |

|

| Tstart | Start time. (Real) |

|

| Tstop | Time for temporary

deactivation. (Real) |

|

| IBC | Deactivation flag of boundary conditions

at impact. (Boolean) |

|

| Inacti | Deactivation flag of stiffness in case

of initial penetrations. 13

(Integer) |

|

| VISs | Critical damping coefficient on

interface stiffness. Default set to 0.05 (Real) |

|

| VISF | Critical damping coefficient on

interface friction. 22

Default set to 1.0 (Real) |

|

| Bumult | Sorting factor is used to speed up the

sorting algorithm and is machine dependent. Default set to 0.20 (Real) |

|

| Ifric | Friction formulation flag. 1617 Only used if fric_ID is not defined.

(Integer) |

|

| Ifiltr | Friction filtering flag. 18

(Integer) |

|

| Xfreq | Filtering coefficient. Default value depends on Ifiltr (Real) |

|

| Iform | Friction penalty formulation type. 19

(Integer) |

|

| sens_ID | Sensor identifier to activate/deactivate

the interface. 24 If an identifier sensor is defined, the activation/deactivation of interface is based on sensor and not on Tstart or Tstop. (Integer) |

|

| fct_IDF | Friction coefficient with temperature

function identifier. Default = 0 (Integer) |

|

| AscaleF | Abscissa scale factor on fct_IDF. Default = 1.0 (Real) |

|

| fric_ID | Friction identifier for friction

definition for selected pairs of parts.

(Integer) |

|

| C1 - C6 | Friction law

coefficient. (Real) |

See Table 1 |

| Kthe | Heat exchange coefficient (if fct_IDK = 0). Default = 0.0 |

|

| Heat exchange coefficient (if fct_IDK

0). 20

Default = 1.0 (Real) |

||

| fct_IDK | Function identifier for thermal heat

exchange definition with contact pressure. Default = 0 (Integer) |

|

| AscaleK | Abscissa scale factor on fct_IDK. Default = 1.0 (Real) |

|

| Tint | Interface temperature. 20 (Real) |

|

| Ithe_form | Heat contact formulation flag.

(Integer) |

|

| NRadm | Number of elements through a 90 degrees

radius. (Integer) |

|

| Padm | Criteria on the percentage of

penetration. Default = 1.0 (Real) |

|

| Angladm | Angle criteria. (Real) |

|

| Frad | Radiation factor. (Real) |

|

| Drad | Maximum distance for radiation

computation. (Real) |

|

| Fheats | Frictional heating factor of secondary.

21

(Real) |

|

| Fheatm | Frictional heating factor of main. 21

(Real) |

Flags for Deactivation of Boundary Conditions: IBC

| (1)-1 | (1)-2 | (1)-3 | (1)-4 | (1)-5 | (1)-6 | (1)-7 | (1)-8 |

|---|---|---|---|---|---|---|---|

| IBCX | IBCY | IBCZ |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| IBCX |

(Boolean) |

|

| IBCY |

(Boolean) |

|

| IBCZ |

(Boolean) |

Comments

- In case of SPMD, each mainr segment defined by surf_IDm must be associated to an element (possibly to a void element).

- For the flag Ibag, refer to the monitored volume option (Monitored Volumes (Airbags)).

- Contact stiffness, K

is computed as:If Istf =1:

(1) If Istf = 2, 3, 4 or 5:(2) If Istf =1000:(3) Where, is computed from both main segment stiffness and secondary node stiffness :

Istf = 2,

Istf = 3,

Istf = 4,

Istf = 5,

is the main segment stiffness and computed as:

When the main segment lies on a shell or is shared by shell and solid:(4) When the main segment lies on a solid:(5) Where,- Segment area

- Volume of the solid

- Bulk modulus

is an equivalent nodal stiffness considered for interface TYPE7, and computed as:

When the node is connected to a shell element:(6) When the node is connected to a solid element:(7) There is no limitation to the value of stiffness scale factor Stfac (but, a value greater than 1.0 can reduce the initial time step).

When using /PROP/VOID and /MAT/VOID, material properties and thickness for the VOID material must be entered; otherwise, the contact stiffness of the void elements will be zero. This is especially important if VOID shell elements share elements with solid elements as the stiffness of the shell elements is used in the contact calculation.

- Istf = 2, 3, 4, or 5 are not compatible with SPH formulation.

- If Icurv = 1, a spherical curvature

is defined for the gap with node_ID1 (center of the sphere).

If Icurv = 2, a cylindrical curvature is defined for the gap with node_ID1 and node_ID2 (on the axis of the cylinder).

If Icurv = 3, the main surface shape is obtained with a bicubic interpolation, respecting continuity of the coordinates and the normal from one segment to the other. In case of a fast and large change in curvature, this formulation might become unstable (will be improved in future version).

Figure 1. - In case of adaptive meshing and Iadm = 1: If the contact occurs in a zone (main side) whose radius of curvature is lower than the element size (secondary side), the element on the secondary side will be divided (if not yet at maximum level).

Figure 2. - In case of adaptive meshing and Iadm = 2:

If the contact occurs in a zone (main side) whose radius of curvature is lower than NRadm times the element size (secondary side), the element on the secondary side will be divided (if not yet at maximum level).

If the contact occurs in a zone (main side) where the angles between the normals are greater than Angladm and the percentage of penetration is greater than Padm, the element on the secondary side will be divided (if not yet at maximum level).

Figure 3. - The coefficients NRadm, Padm, and Angladm are used only if adaptive meshing and Iadm=2.

- If Gapmax=0, there is no maximum value for the gap.

- If Gapmin=0 or blank, a default value

is computed as:

If main segments are shell and solid elements, Gapmin = min ( , ).

Where,- The average thickness of the main shell elements, for Igap=0

- The minimum thickness of the main shell elements, for Igap=1, 2, or 3

- The smallest side length of all main segments (shell or brick)

If main segments are all solid elements Gapmin =

Where, being the smallest side of all main brick segments.

- Variable gap:If Igap =1, variable gap is computed as:

(8) If Igap =2, variable gap is computed as:(9) If Igap =3, variable gap is computed for self-contact as:(10) Where,-

: main element gap

: with being the thickness of the main element for shell elements

: for brick elements

-

: secondary node gap

: if the secondary node is not connected to any element or is only connected to brick or spring elements

: with being the largest thickness of the shell elements connected to the secondary node

: for truss and beam elements. With being the cross section of the element

- : length of the smaller edge of element

- : length of the smaller edge of elements connected to the secondary node

If the secondary node is connected to multiple shells and/or beams or trusses, the largest computed secondary gap is used.

The variable gap is always at least equal to Gapmin.

-

: main element gap

- Deactivation of the boundary condition is applied to secondary nodes group (grnd_IDs).

- Inacti = 3 may create initial

energy if the node belongs to a spring element.Inacti = 6 is recommended instead of Inacti =5, in order to avoid high frequency effects into the interface.

Figure 4.If Fpenmax is not equal to zero, nodes stiffness is deactivated if:

whatever the value of Inacti.

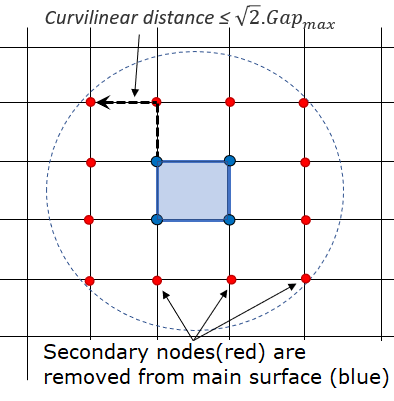

- With Irem_gap = 2, it allows to have the element size smaller than gap values:

Figure 5. Secondary nodes removed from node to surface contactFor self-impact contact, when Curvilinear Distance (from a node of the main segment to a secondary node) is smaller than (in initial configuration), this secondary node will not be taken into account by this main segment, and it will not be deleted from the contact for the other main segments.

- One node can belong to the two surfaces at the same time.

- If fric_ID is defined, the contact friction is defined in /FRICTION and the

friction inputs (Ifric, C1,

and so on) in this input card are not used.

For friction formulation:

If the friction flag Ifric=0 (default), the old static friction formulation is used:

with being the Coulomb friction coefficient- If fct_IDF = 0:Ifric is the Coulomb friction.

(11) - If fct_IDF ≠ 0:Fric becomes a scale factor of Coulomb friction coefficient which depends on the temperature.

(12)

While is the temperature which is taken as the mean temperature of secondary and main:(13) For flag Ifric > 0, new friction models are introduced. In this case, the friction coefficient is set by a function ( ).

Where,- Pressure of the normal force on the main segment

- Tangential velocity of the secondary node relative to the main segment

- If fct_IDF = 0:

- Currently, the coefficients C1 through C6 are used to define a variable friction

coefficient

for

new friction formulations.The following formulations are available:

- Ifric = 1 (Generalized

Viscous Friction law):

(14) - Ifric = 2 (Modified Darmstad

law):

(15) - Ifric = 3 (Renard

law):

(16) (17) (18) Where for Ifric=3:- , static coefficient of friction, must be

- , dynamic coefficient of friction, must be

- , maximum coefficient of friction

- , minimum coefficient of friction

- , first critical velocity, must be > 0

- , second critical velocity, must be

- Ifric = 4 (Exponential decay friction law)The frictional coefficient is assumed to be dependent on the relative velocity of the surfaces in contact according to:

(19)

Table 1. Units for Friction Formulations Ifric Fric C1 C2 C3 C4 C5 C6 1 2 3 4 - Ifric = 1 (Generalized

Viscous Friction law):

- Friction filtering:If Ifiltr flag 0, the tangential forces are smoothed using a filter:

(20) Where,- Filtered tangential force.

- Calculated tangential force at time t before filtering.

- Filtered tangential force at the previous time step

- Current simulation time

- Current simulation time step

- Filtering coefficient

Where coefficient is calculated from:- If Ifiltr = 1: , simple numerical filter with a value between 0 and 1.

- If Ifiltr = 2: , standard -3dB filter, with the number of time steps to filter defined as , and is the filtering period.

- If Ifiltr = 3: , standard -3dB filter, with Xfreq = cutting frequency.

- Friction penalty formulation Iform:

- If Iform = 1 (default) viscous

formulation, the friction forces are:

(21) While an adhesion force is computed as:(22) - If Iform = 2, stiffness

formulation), the friction forces are:

(23) While an adhesion is computed as:

with

Where, is the tangential velocity of the secondary node relative to the main segment.

Iform = 2 is recommended for implicit and explicit analysis.

- If Iform = 1 (default) viscous

formulation, the friction forces are:

- Heat exchange:By Ithe =1 (heat transfer activated) to consider heat exchange and heat friction in contact.

- If Ithe_form = 0, then heat exchange is between shell and constant temperature contact Tint.

- If Ithe_form = 1, then heat exchange is between all contact pieces.

Tint is used only when Ithe_form= 0. In this case, the temperature of main side assumed to be constant (equal to Tint). If Ithe_form=1, then Tint is not taken into account, for the nodal temperature of main side will be considered.

Heat exchange coefficient:- If fct_IDK = 0, then Kthe is heat exchange coefficient and heat exchange depends only on heat exchange surface.

- If fct_IDK ≠ 0, then Kthe is a scale factor and the heat exchange

will depend on the contact pressure:

(24) - While is the function of fct_IDK.

- Heat Friction:

- Frictional energy is converted into heat when Ithe > 0 for interface Type 7 only.

- Fheats and

Fheatm are defined as the

fraction of frictional energy and distributed respectively to the secondary side and

main side. So generally:

(25) When both Fheats and Fheatm are equal to 0, the conversion of the frictional sliding energy to heat is not activated.

- The frictional heat QFric is defined:

- If Iform= 2 (a stiffness

formulation):Secondary side:

(26) Main side:(27) (Ithe_form= 1) - If Iform= 1 (a penalty

formulation):Secondary side:

(28) Main side:(29) (Ithe_form= 1)

- If Iform= 2 (a stiffness

formulation):

- Radiation:Radiation is considered in contact if and the distance, , of the secondary node to the main segment is:

(30) While is the maximum distance for radiation computation. The default value for is computed as the maximum of:- Upper value of the Gap (at time 0) among all nodes

- Smallest side length of secondary element

It is recommended not to set the value too high for , which may reduce the performance of Radioss Engine.

A radiant heat transfer conductance is computed as:(31) with(32) Where,- Stefan Boltzman constant

- Emissivity of secondary surface

- Emissivity of main surface

- If the time step of a secondary node in this contact becomes less than dtmin, the secondary node is deleted from the contact and a warning message is printed in the output file. This dtmin value takes precedence over any model interface minimum time step entered in /DT/INTER/DEL.

- When sens_ID is defined for activation/deactivation of the interface, Tstart and Tstop are not taken into account.

- It is necessary to activate the option Idel= -1 or -2 for parts with SOL2SPH formulation (/PROP/TYPE14 (SOLID)).