Shrink Wrap Meshing

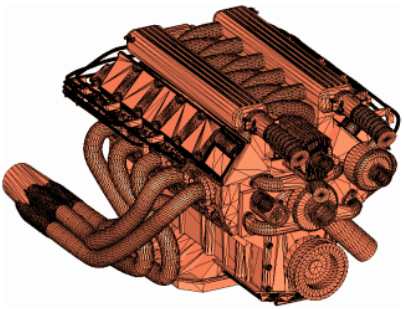

Shrink wrap meshing is a method to create a simplified mesh of a complex model when high-precision models are not necessary, as is the case for powertrain components during crash analysis.

|

|

- Shrink wrap allows for wrapping of multiple components if they are selected.

- Selection provides the option to wrap all nodes, elements, components, surfaces, points, or solids, or only a certain portion of the model if desired. The input to the shrink wrap, that is, the model parts that you wish to wrap, can consist of 2D or 3D elements along with surfaces or solids.

One use case for shrink wrapping is when you need to convert an .stl representation of a model into a tria/quad mesh; using shrink wrap provides a quick and efficient way of achieving this. Similarly, crash analysis does not require a highly-detailed powertrain model; in such cases you can use the shrink wrap mesh to quickly generate a simplified approximation of a detailed powertrain model. Crash analysts can then use that coarser shrink wrap representation within the crash simulation model.

Other reasons to use the shrink wrap include being able to stitch over very bad geometry to generate an enclosed volume mesh for tetra-meshing. The shrink wrap tool can work from elements, whether 2D or 3D, or geometry. Thus, in the case of an "unclean" geometry model with many released (free) edges, you can either generate any arbitrary mesh on the unclean geometry using the automesh functionality beforehand and then creating shrink wrap or you can simply select the surface or solid without meshing the geometry first; either of these steps will yield good output mesh. The key in such cases is to ensure that the element size used for the shrink wrap is large enough to stitch over the unclean surface edge splits so that an enclosed volume can be created.

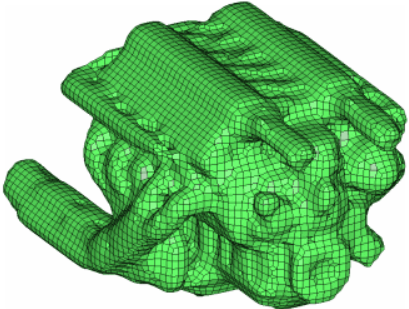

Shrink wrap mesh can be generated as a surface mesh, using a loose or tight wrapping, or as a full-volume hex mesh by use of the Shrink Wrap panel. The distinction between surface or volume mesh is an option labeled generate solid mesh.