Perform Spray Coating Analysis

The EDEM spray coating post-processing tools use a ray tracing approach that offer key advantages over the legacy Spray Coating model.

-

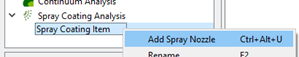

In EDEM Analyst, right-click Spray

Coating Analysis in the Analyst tree, and then select

Add Spray Coating Item.

- Specify a name for the coating.

-

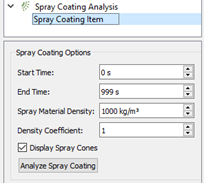

In the Spray Coating Analysis dialog box, specify the

following details:

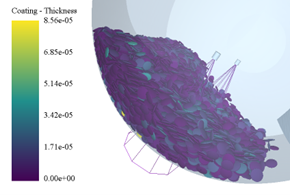

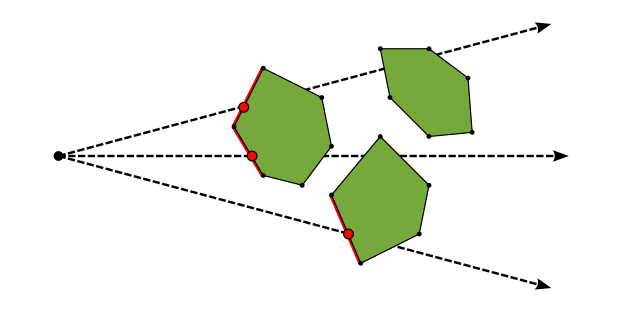

For Specify Start Time Indicates the start time at which spray coating should be applied End Time Indicates the end time at which spray coating should be applied Spray Material Density Indicates the density of the coating substance, which will only be used to calculate the coating volume and thickness Density Coefficient Indicates a dimensionless number that controls the number of ray-tracing rays. In general, higher numbers mean a slower but more detailed analysis. A density coefficient of 1.0 is roughly equivalent to one ray per particle face for a particle at the furthest distance from the spray. Display Spray Cones Select the check box to display the direction and position of the spray cones. For more information about how Spray paths are uniformly distributed in a cone formation, see How it works. Analyze Spray Coating Click to start the spray coating analysis. A console displays the progress of the calculation. If you click Cancel to end the analysis earlier, partial results will still be saved.

-

Right-click the spray coating item and select Add Spray

Nozzle.

You can also add multiple nozzles.

-

Specify the following details to configure per-spray:

For Specify Mass Flow Indicates the rate at which this nozzle outputs coating material Max Angle Indicates the full angle of the nozzle’s spray cone from one edge to the other. This must be more than 0deg (spray leaves the nozzle in a straight line) and less than 180deg (spray leaves in any direction, except backwards). Spray Zone Length Indicates the maximum distance from the nozzle that spray particles can travel and is used to calculate the required ray density. Particles outside this range are ignored. It is important to make this length long enough to capture all particles, but not longer than is necessary as the performance may decrease due to the increased ray density.

Origin and Rotation settings Select a setting to control the position and angle of the spray nozzle. -

To view plots of the average intra-particle coating distribution, open your web

browser.

When the analysis is complete, the plots are automatically displayed and saved as .html files, located next to the simulation’s .

demfile.

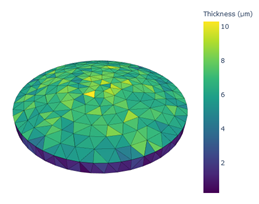

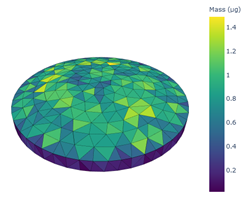

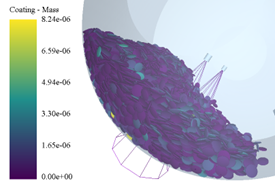

The analysis also adds custom properties to the deck that displays the coating mass and thickness as applied to each particle.The custom property values are in base SI units (kg and m respectively).

The analysis also adds custom properties to the deck that displays the coating mass and thickness as applied to each particle.The custom property values are in base SI units (kg and m respectively).

How it works

Spray Coating Advantages and Limitations

- It runs in the Analyst, so different spray configurations can be analyzed without re-simulating the deck (post-processing).

- It provides information about the average coating distribution for each face on the surface of the particle (intra-particle).

-

Only polyhedral particles are currently supported.

- Uses data only from saved Time Steps. Use a small save interval for accurate results.

- The ray-tracing approach assumes that droplets reach their target instantly, and influences such as gravity are not considered.