Mesh Convergence

![]()

Introduction

Convergence study is an approach to accomplish a mesh which give us confident over the result we get from that mesh. The study can be done by local mesh refinement for each iteration. The locations where the mesh is to be fine are identified and existing solid mesh on those locations will be converted into fine mesh. Here the model setup like loads, boundary conditions and solver settings will remain as such in each iteration.

At the end of each iteration, if the percentage of change in response is less than allowable value or all the iterations are completed, then the convergence process will be stopped. If not, the strain energy error density is calculated and locations where strain energy error density is more than 25% of maximum error are identified as the regions where mesh should be fine.

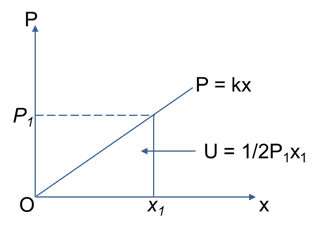

Strain Energy Density

Work done on a system will be stored as strain energy. Consider a rod with axial load, the strain energy stored in the rod is 1/2P1x1

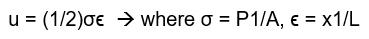

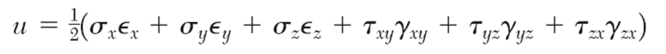

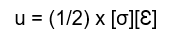

Strain energy density U/V = u = (1/2P1x1) / (AL)

Extending the same to the general state of stress, strain energy density is

Strain Energy Error Density

When the solver is requested for element nodal values, the stress tensor at a node may not be continuous. The values may not same at a node for all the elements connected to it. When averaging all the values of that node, we will get a continuous contour across the elements.

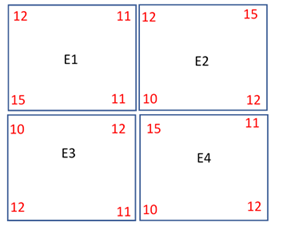

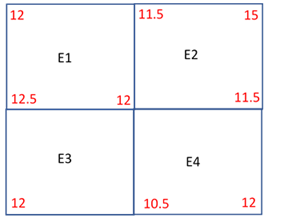

Assume the images given below show the "Not Averaged" and "Averaged" value of normal stress in x axis.

| Not Averaged | Averaged |

|---|---|

|

|

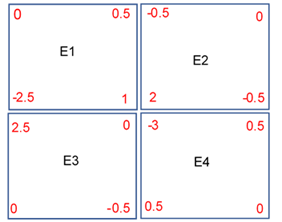

The error of normal stress in x axis for each element = "Averaged" - "Not Averaged"

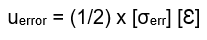

Similarly, the error in all stresses form error stress tensor. Similar to strain energy density, strain energy error density is

Setting up mesh convergence

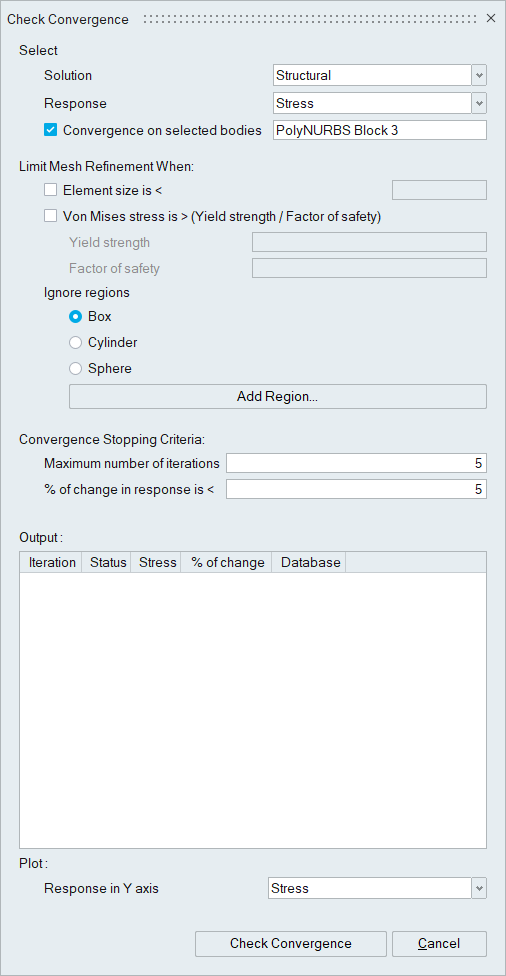

Convergence study can be set up for OptiStruct linear static structural solution. Select the solution, response and Tet mesh bodies for convergence study.

Limit Mesh RefinementThe mesh refinement can be limited to minimum element size. In addition, mesh refinement can be limited were Von Mises stress is greater than Yield strength/Factor of safety when one solid body is selected for convergence. Mesh refinement can be further limited by ignoring regions which are identified as non-interested or it might lead to stress concentration.

Convergence Stopping Criteriaconvergence process can be stopped by both number of iterations and percentage of change in response in successive iteration.

Output

The output table allows to open data base for each iteration.