/H3D/SOLID

Engine Keyword Generate H3D contour output results for /BRICK, /BRIC20, /TETRA4, /TETRA10 solid elements and /BRICK, /PENTA6, /SHEL16 thick shells.

Format

/H3D/SOLID/Keyword3/Keyword4/Keyword5

#optional next line(s) that lists the parts to save results for.

part_ID1... part_IDN

Example

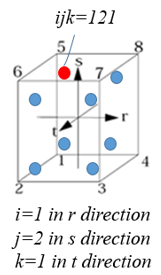

/H3D/SOLID/TENS/STRESS/IR=1/IS=2/IT=1

Figure 1.

/H3D/SOLID/TENS/STRESS/IR=ALL/IS=ALL/IT=ALL/H3D/SOLID/ENER

1 55 75Definition

Comments

- The syntax /H3D/ELEM/Keyword3/Keyword4/Keyword5 is also valid.

- When PART IDs are listed after the /H3D/SOLID line the specified results will only be output for those parts.

- Output can be a Scalar or Tensor as

defined in the following tables.

Table 1. Scalar Output Keyword3 Keyword4 Keyword5 Description AMS Elements using AMS timestep due to /DT/CST_AMS. DAM1, DAM2, DAM3 Principal damage values in local cracking skew direction 1, 2 or 3 for material LAW24 with /BRICK elements. DAMA - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Maximum of damage over time of all /FAIL criteria acting on one material. If Keyword4 is blank, the maximum integration point value in the element is output.

Refer to the specific /FAIL law used for how damage is calculated.

TMAX Maximum of damage over time, integration points and failure models. DAMG Mean damage over integration points (only for coupled damage models). DAMINI - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Maximum damage initiation variable among all failure criteria using initiation variable before computing stress softening (/FAIL/INIEVO). DENS Density DOMAIN SPMD domain number of an element. DT Element timestep EINT Internal energy ( eV) EINTM Specific internal energy (e) EINTV Internal energy density ( e) ENER Specific energy density (internal energy divided by the element mass) TMAX Maximum specific energy density over time ENTH Enthalpy (e+pV) ENTHM Massic enthalpy (e + pV) / m ENTHV Enthalpy density (e/V +p) EPSD Equivalent strain rate EPSP Plastic Strain FAILURE ID= fail_ID or ALL - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Damage of a specific failure criterion references by its optional identifier fail_ID defined in the Starter file. FILL Filling percentage for /INIBRI/FILL FLDF OUTER OUTER_AVERAGE

FLD damage factor indicator. 6 FLDZ OUTER OUTER_AVERAGE

FLD failure zone factor for the FLD failure model. - = 1

- Loose metal

- = 2

- High wrinkle

- = 3

- Compression

- = 4

- Safe

- = 5

- Marginal

- = 6

- Failure 6

GROUP Internal group identifier HOURGLASS Hourglass energy per mass unit MASS Element mass MDS MDS user variables. Automatic selection of user variable to output according to MDS law that is used.

(mean value with all solid integration points)

- MDS_VAR =

- DEF or ALL

MDS user variables. (mean value with all solid integration points)

NL_EPSD Non-local plastic strain rate (only if /NONLOCAL/MAT is activated) 6 NL_EPSP Non-local plastic strain (only if /NONLOCAL/MAT is activated) 6 OFF Element status. Where the result output is:- = -1

- Element is not active (it is defined in an activated rigid body).

- = 0

- Deleted element.

- Between 0 and 1

- Under failure process.

- = 1

- Active element.

ORTHD - LAYER=

- i or ALL

- IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Euler angles in degrees defining the rotation matrix to go from global reference system to orthotropic reference system. To request a specific angle use ORTHD/PSI, ORTHD/THETA, or ORTHD/PHI.

P Pressure PEXT External pressure applied on solid element coming from /PLOAD, /LOAD/PFLUID, /LOAD/PBLAST or /LOAD/PRESSURE. The outer skin is automatically created to display the pressure.

SIGEQ Equivalent stress based on a material’s yield criteria. Some examples of yield criteria are von Mises, Hill or Barlat. TMAX Maximum equivalent stress based on a material’s yield criteria over time and integration points. SIGX, SIGY, SIGZ, SIGXY, SIGYZ, SIGZX Mean element stress in specified direction. TEMP Temperature TDEL Time at which element is deleted due to failure defined using /FAIL criterion. Failure criteria built in materials is ignored. THICK Average thickness for thick-shell elements (/PROP/TYPE20, /PROP/TYPE21, /PROP/TYPE22). THIN Average % thinning for thick-shell elements (/PROP/TYPE20, /PROP/TYPE21, /PROP/TYPE22). TILLOTSON Region identifier for Tillotson Equation of State (/EOS/TILLOTSON) TSAIWU Tsai Wu criterion for material /MAT/LAW12 (3D_COMP), /MAT/LAW14 (COMPSO) and /MAT/LAW25 (COMPSH) USER - UVAR=

- i or ALL

- IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

User material (/MAT/USERij) law output for user-defined variable i. Also, requests USR output for some Radioss material laws such as LAW59 or LAW70. USR1 output is requested using UVAR=1. For integration point results, use IR, IS and IT options. VDAM1 - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Value of damage factor D, for /FAIL/SNCONNECT. VDAM2 - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Value of damage surface for /FAIL/SNCONNECT. VDAM3 - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Value of rupture surface for /FAIL/SNCONNECT. VONM Mean element von Mises stress TMAX Maximum von Mises stress at over time and integration points WPLA Plastic work for /MAT/LAW12 (3D_COMP) and /MAT/LAW25 (COMPSH) Table 2. Scalar ALE and CFD Output Keyword3 Keyword4 Description BFRAC Burn fraction BULK Artificial viscosity COLOR 1*vfrac1 + 2*vfrac2 + .... + last*vfracN (LAW51 and LAW151 only). DIV(U) Volumetric dilatation rate K Specific for turbulent energy in CFD. MACH Mach number (/MAT/LAW151 only) MOM Cell momentum Density (MOM) for FVM with Interface TYPE22 for all components and magnitude. To request each separately use, MOMX, MOMY, MOMZ, MOMXY, MOMYZ, MOMXZ, |MOM|. SCHLIEREN Schlieren image (optical method widely used in CFD field). ALE material laws. SSP Sound speed. Only available with ALE material laws. TDET Detonation time output. TVIS Specific for turbulent viscosity in CFD. VEL Cell velocity for FVM with Interface TYPE22 for all components and magnitude. To request each separately use, VELX, VELY, VELZ, VELXY, VELYZ, VELXZ, |VEL|. VFRAC All volumetric fractions (for ALE multi-material laws: LAW20, LAW37, LAW51 and LAW151). VFRAC1,VFRAC2, VFRAC3,VFRAC4 Volumetric fractions (for ALE multi-material laws: LAW20, LAW37 and LAW51). VORT, VORTX, VORTY, VORTZ Vorticity for ALE material in resultant, X, Y, and Z components. VECT VEL Velocity vectors at finite volume cell centroids. CONT Contact force vectors at finite volume cell centroids. Table 3. Tensor Output Keyword3 Keyword4 Keyword5 Description TENS BSTRESS - ID=

- n or ALL

- IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Backstress tensor for material /MAT/LAW36 (n=1) and /MAT/LAW78 (n=1, 2 or 3). ID=-1 returns the sum of all backstress tensors available for the element.

DAMA Cracks tensor at integration points for Material LAW24 only. If Keyword5 is blank, the mean value in the element is output.

EPSP - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Plastic strain tensor at integration points, only available for /MAT/LAW24 with Icap=2. If Keyword5 is blank, the mean value element is output.

STRAIN - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Strain tensor at integration points. If Keyword5 is blank, the mean value in the element is output.

TMAX Strain tensor corresponding to the maximum principal strain (P1) over time and integration points. Strain tensor corresponding to the minimum principal strain (P3) over time and integration points.

OUTER Membrane strain tensor on the outer surface of a solid or thick shell component. The membrane layer is automatically created, and the solid strain tensor is extrapolated to this surface. CORNER_DATA Strain tensor saved for all nodes of each element (not available for /SHEL16 or /BRICK20). STRAIN_ENG -- Infinitesimal total strain. Only one tensor per element. STRESS - IR=

- i or ALL

- IS=

- j or ALL

- IT=

- k or ALL

Stress tensor at integration points. If Keyword5 is blank, the mean value in the element is output. TMAX Stress tensor corresponding to the maximum principal stress (P1) over time and integration points. Stress tensor corresponding to the minimum principal stress (P3) over time and integration points.

OUTER Membrane stress tensor on the outer surface of a solid or thick shell component. The membrane layer is automatically created, and the solid stress tensor is extrapolated to this surface. CORNER_DATA Stress tensor saved for all nodes of each element (not available for /SHEL16 or /BRICK20) - To request integration point results, use /IR=i/IS=j/IT=k notation where the options can be entered in any order.

- Option DAMG is

only used with coupled damage models (/MAT/LAW72 or

/FAIL/GURSON) to output damage over integration points.

The damage variable is normalized by its critical value.

- For /MAT/LAW72

(1) - For /FAIL/GURSON

(2)

- For /MAT/LAW72

- If /NONLOCAL/MAT option is activated, it is possible to output the regularized non-local plastic strain and its rate.

- The damage initiation variable /H3D/SOLID/DAMINI is used with some failure criteria such as /FAIL/INIEVO, which first computes a damage initiation criterion before computing the stress softening damage variable, which can be plotted with /H3D/SOLID/DAMA.