Routing Slit

Check the rule for the routing slit on the PCB design.

The Routing Slit dialog contains the following

sections:

- Routing Slit Layer Definition

- Layer Selection: Select routing-slit layer from the artwork layer list.

- Laser Via Definition: Define the laser via with the hole size or selection

from the library list.

- Maximum Via Hole Size: Set the maximum value of hole size.

- Padstack List: Select the via using padstack name.

- Padstack String: Define the via using string filter.

- Import(.txt): Apply Filter Type based on the characters

entered in the .txt file.

- Apply as a prefix when (|F|) ABC is entered in the .txt file.

- Apply as a mid-string when ABC is entered in the .txt file.

- Apply as a suffix when ABC(|P|) is entered in the .txt file.

- Export(.txt): Export the characters registered in the String Item in .txt file format.

- Import(.txt): Apply Filter Type based on the characters

entered in the .txt file.

- Option

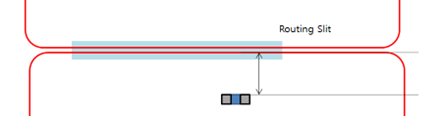

- Expand Routing Slit: Extend the Routing Slit area by the entered value.

- Recognize Measure-Base as line which overlapped on Routing Slit:

Recognize the overlapping area of the Routing Slit layer that is

defined in the Layer Selection and the line drawn on a specific

layer as a measure base.

- Select layer for line object: Select a layer where the target line is drawn.

- Measure Base: Select the measure base of the Line with

either Edge or Center.

Figure 1.

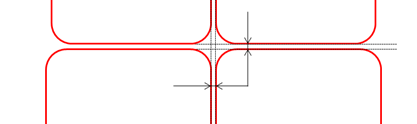

- Routing Slit Hole Checking: Check the routing slit hole size and width.

- Routing Slit Hole Size Range: Set a slit hole size ranges.

- Check Slit Width with Distance between Board Outlines: If slit width

is defined by the distance with single boards, specify the distance

value. If the distance between single boards is too close, it could

create errors while drilling.

Figure 2.

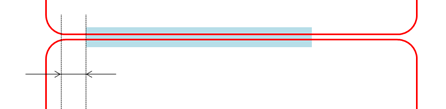

- Routing Slit Clearance Checking

- Maximum Routing Slit’s Size Checking: Check the routing slit size.

- Clearance to PCB Outline: Set the clearance value between the routing slit and PCB outline.

- Clearance to Hole: Set the clearance value between the routing slit and drill holes in the design.

- Clearance between Routing Slits: Set the clearance value between the routing slits for horizontal and vertical directions.

- Clearance to PCB Outline’s Corner: Set the clearance value between

the routing slit and PCB outlines corner.

Figure 3.

- Option: Define a fail if all of the PCB’s corners fail: When checking the routing slit clearance to the PCB corner, even if one side passes and the other side fails, it does not fail.

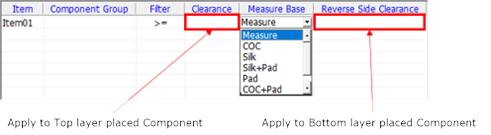

- Clearance to Component

- Recognize Selected Component’s Placed Side as Top: To define the layer, select the component. UsePollEx DFM to recognize the top layer with selected components placed layer.

- Components’ Clearance Table: For a different component

group, define the clearance value for the placed layer and

the other side layer.

Figure 4.

- Clearance to Remainder (Not belong to any Group): Set the clearance value between the routing slit and components which are not listed in the component clearance table.

- Exceptional Component Group: Select the void-checking component group.

- Clearance to Routing

- Clearance to Routing Patterns: Set the clearance value

between the routing slit and pattern.

- Check only for same or smaller width pattern than given value: Use PollEx DFM to check for a thin routing pattern than give the width value.

- Clearance to Copper-Pour: Set the clearance value between the routing slit and copper–pour.

- Clearance to Routing Patterns: Set the clearance value

between the routing slit and pattern.

- Depanelized Tab Checking

- Searching range from each routing slit object (to recognize

depanelized tab area): Search range for recognizing depanelized

tabs.

- **If the distance between Routing Slit Groups exceeds the search range, it is not recognized as a tab area.

- Minimum Tab length: If the length of the tab is less than the input value, it is fail.

- Maximum Tab length: If the Tab length exceeds input value, it is fail.

- Clearance between Component and Tab area.

- Remainder (Not belong to any component group)

- Measure Base

- Clearance for Top

- Clearance for Bottom

- Clearance between Routing Patterns and Tab area.

- Clearance between Copper-Pour and Tab area.

- Clearance between Via and Tab area.

- Clearance between Laser Via and Tab area.

- Searching range from each routing slit object (to recognize

depanelized tab area): Search range for recognizing depanelized

tabs.

- Via Clearance

- Common Via Clearance

- Routing Slit to Via in Copper-Pour: Set the clearance value between the routing slit and the via in copper-pour.

- Routing Slit to Via in Routing Pattern: Set the clearance value between the routing slit and the via in routing patterns.

- Laser Via Clearance

- Routing Slit to laser Via in Copper-Pour: Set the clearance value between the routing slit and laser via in copper-pour.

- Routing Slit to laser Via in Routing Pattern: Set the clearance value between the routing slit and laser via in routing patterns.

- Common Via Clearance