PCB Mark

Recognize a single board by machinery and check the rules about PCB marks.

The PCB Mark dialog contains the following

sections:

- PCB Mark definition: Define the PCB marks in the design.

- Component Group Selection: If the PCB mark is designed with a

component, specify the component group.

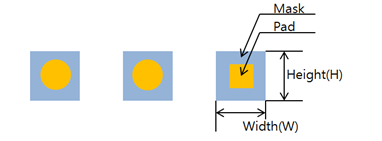

- Mask(S/R) Size (SS): Set the PCB mark with the outer mask size.

- PAD Size (PS): Set the PCB mark with the inner pad size.

- Recognize conductive figure shape as Pad: Recognize an object that is drawn with the figure shape in the conductive layer as a Pad.

- Board Figure Geometries: If the PCB mark is defined with board

figure geometries, specify the size of the pad and mask sizes.

- Mask1(S/R) Size (SS): Set the PCB mark with the outer mask size.

- PAD1 Size (PS): Set the PCB mark with the inner pad size.

- Mask2(S/R) Size (SS): Set the PCB mark with the outer mask size.

- PAD2 Size (SS): Set the PCB mark with the inner pad

size.

Figure 1.

- Component Group Selection: If the PCB mark is designed with a

component, specify the component group.

- Except checking PCB Mark:

- Major Axis Length <: Exclude the PCB Mark when the PCB major axis is shorter than the setting value.

- Checking

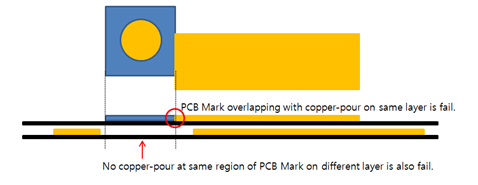

- Copper Existence Check: Use PollEx DFM to

check copper-pours at the same region of the PCB mark. On the same

layer, copper-pour cannot be overlapped with the PCB mark, but on

other layers, there should be copper-pour around the PCB mark.

Figure 2.

- Placement: Check the placement status of the PCB mark.

- PCB Mark Placed Side(s): Select the layer and use PollEx DFM to check the PCB mark.

- Count: Count the maximum, minimum, or exact number of PCB Marks in the design.

- Exceptional PCB Mark Component: Set the void-checking component group.

- PCB Mark Placed Side(s): Select the layer and use PollEx DFM to check the PCB mark.

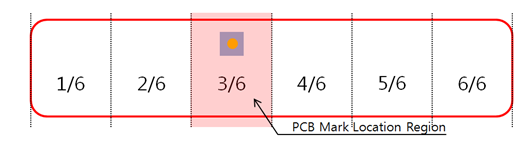

- PCB Mark Existence:

- Normal Checking:

- Number of PCB Region: Give the number of regions to divide the PCB.

- PCB Mark Existing Region: Set the region where the

PCB mark is located..

Figure 3.

- Detail Checking:

- The Long Size of PCB: Input the value of a long size range of the PCB.

- Criteria for Count: Select an inequality sign for checking the PCB mark count.

- Minimum Count per Area: Input the minimum number of PCB Marks that should exist in the checking area.

- PCB Mark Existing Region: Set the region where the

PCB Mark is placed.

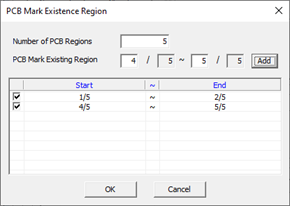

Figure 4.

- Number of PCB Region: Set the number of regions to divide the PCB.

- PCB Mark Existing Region: Set the region where the PCB mark is located.

- Normal Checking:

- Silkscreen Overlapping: To check the PCB mark overlap with silkscreen, set comparing GERBER layer for the top and bottom.

- Clearance Checking:

- Component: To check the clearance between the PCB mark and components, set the clearance value.

- Route Patterns: To check the clearance between the PCB mark and route patterns, set the clearance value.

- Copper-pour: To check the clearance between the PCB mark and copper-pour, set the clearance value.

- Via: To check the clearance between the PCB mark and vias, set the clearance value.

- Board Outline: To check the clearance between the PCB mark and the board outline, set the clearance value.

- Copper Existence Check: Use PollEx DFM to

check copper-pours at the same region of the PCB mark. On the same

layer, copper-pour cannot be overlapped with the PCB mark, but on

other layers, there should be copper-pour around the PCB mark.