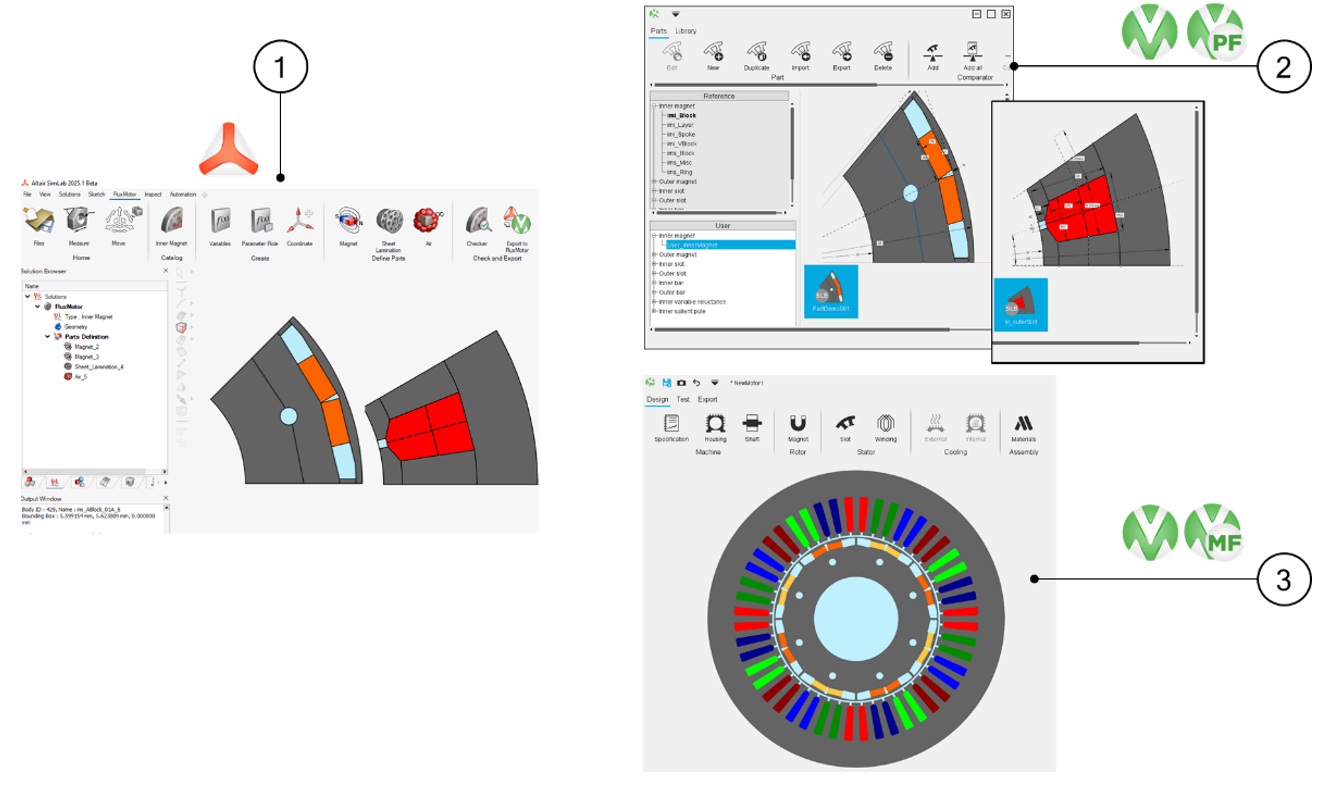

Introduction of FluxMotor Solution

The FluxMotor Solution integrates seamlessly with SimLab tools, including

Import (Database, CAD, or Sketch) and the Sketch Environment, to

provide a comprehensive workflow for creating and exporting parts compatible with

FluxMotor. Users can perform the following workflows within this solution:

- Customize catalog parts: Modify existing parts from the catalogs by adjusting design details or adding new features.

- Create a part from scratch: Define a custom FluxMotor part using the basic sector template, specifying the inner diameter, outer diameter, and the number of repetitions within a motor.

- Import from CAD: Generate a FluxMotor part by importing a CAD model, either of a specific part or the entire motor assembly.

For each part, users can assign physical regions to specific bodies, checking compatibility with FluxMotor and stress testing the part before exporting. The output format is optimized for import into FluxMotor, supporting subsequent performance analysis.