/MAT/LAW126 (JOHNSON_HOLMQUIST_CONCRETE)

Block Format Keyword This material law describes the behavior of brittle materials, more specifically dedicated to concrete.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW126/mat_ID/unit_ID or /MAT/JOHNSON_HOLMQUIST_CONCRETE/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| G | |||||||||

| a | b | n | T | ||||||

| c | FCUT | ||||||||

| PC | PL | ||||||||

| K1 | K2 | K3 | |||||||

| D1 | D2 | IDEL | IFAILSO | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| G | Shear modulus. (Real) |

|

| A | Normalized cohesive

strength. (Real) |

|

| B | Normalized pressure hardening

modulus. (Real) |

|

| N | Pressure hardening

exponent. (Real) |

|

| Quasi-static uniaxial compressive

strength. (Real) |

||

| T | Maximum hydrostatic tensile

pressure. (Real) |

|

| C | Strain rate coefficient.

(Real) |

|

| Reference strain rate. Default = 1.0 (Real) |

||

| FCUT | Cutoff frequency for strain rate filtering.

(Real) |

|

| Maximum normalized

strength. Default = 1020 (Real) |

||

| Minimum fracture strain. Default = 10-20 (Real) |

||

| PC | Crushing

pressure. (Real) |

|

| Crushing volumetric

strain. (Real) |

||

| PL | Locking

pressure. (Real) |

|

| Locking plastic volumetric

strain. (Real) |

||

| K1 | Linear bulk

stiffness. (Real) |

|

| K2 | Quadratic bulk

stiffness. (Real) |

|

| K3 | Cubic bulk

stiffness. (Real) |

|

| D1 | Damage

parameter. (Real) |

|

| D2 | Damage

exponent. (Real) |

|

| IDEL | Element failure criteria flag:

(Integer) |

|

| Critical plastic strain for element

deletion. Default = 1020 (Real) |

||

| IFAILSO | Element post-failure behavior flag (if

IDEL > 0).

(Integer) |

Example (Concrete)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

Unit for material

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW126/1/1

Concrete

# Init. dens.

2.440E-9

# G

14860

# A B N FC T

0.79 1.60 0.61 48 4

# C EPS0 FCUT SFMAX EFMIN

0.007 1.0 10000 7 0.01

# PC MUC PL MUL

16 0.001 800 0.1

# K1 K2 K3

85000 -171000 208000

# D1 D2 IDEL EPS_MAX IFAILSO

0.04 1.0 3 0 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This material law is based on the theory of Johnson-Holmquist-Cook model theory (also called Johnson-Holmquist-Concrete). It was proposed and designed for a concrete application. In this model, the spherical and deviatoric behavior are separated. It considers the effect of damage and strain rate sensitivity.

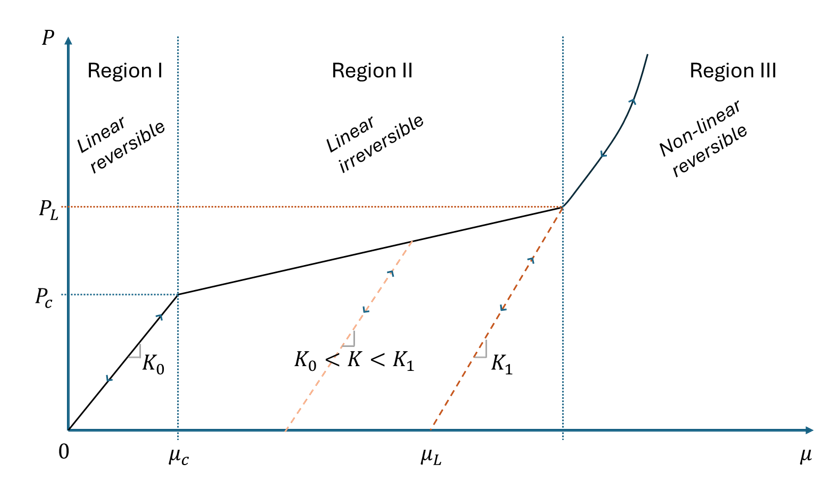

- The spherical behavior is described with a constitutive equation

based on hydrostatic pressure (considered positive in compression). This

behavior is divided into 3 regions (Figure 1) in the evolution hydrostatic pressure versus

volumetric strain denoted

.In the first region, the pressure response is supposed linear and elastic. In the second region, the microcavities of the material are supposed to be crushed, generating a plastic volumetric strain denoted , modifying linearly the bulk modulus from and . When all the cavities have been crushed and the material becomes fully dense. Then, the pressure evolution follows a polynomial equation of state.

Figure 1. Hydrostatic pressure variation with respect to volumetric strain

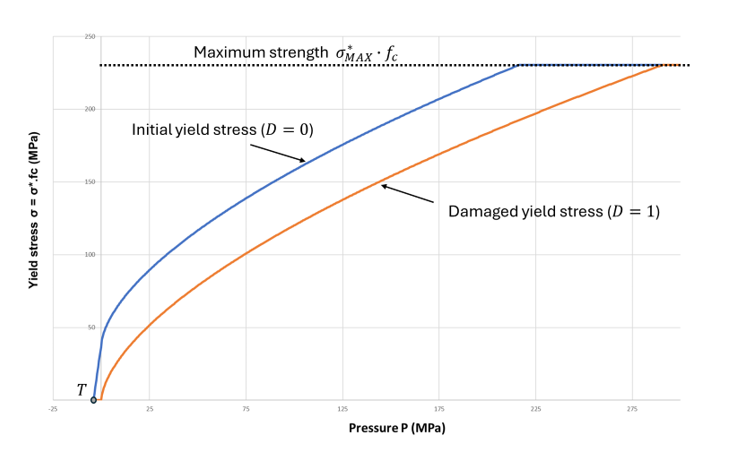

- The deviatoric behavior is defined with an elasto-plastic behavior,

where the normalized yield stress is both a yielding and a damaging limit.

Its expression is:

- If

(compressive

loadings):

Where, bounded by .

- If

(tensile loadings):To get the yield stress, the normalized value is multiplied by . These two yield stresses shapes (for compressive and tension loadings) are plotted for a damage value of 0 (initial material) and 1 (fully fractured material) in Figure 2:

Figure 2. Yield stress evolution with respect to hydrostatic pressure

To trigger the deviatoric elasto-plastic behavior, the normalized yield stress is compared to the current normalized equivalent von Mises stress:

This allows to compute the evolution of the deviatoric plastic strain denoted .

- If

(compressive

loadings):

- The damage variable evolution is dependent to both volumetric and

deviatoric plastic strain. Its expression is given by:

Where, the effective strain at failure is defined by:

- Time history and animation output is available using these USRi variables.

- USR1: Plastic volumetric strain

- USR2: Bulking pressure

- USR3: Volumetric strain

- USR4: Yield stress

- Strain rate filtering can be used and activated when a cutoff frequency FCUT for filtering is defined.

- The damage variable can be plotted in ANIM and H3D file using the output option DAMG.

- To avoid damage mesh dependency, due to mesh size or orientation,

the non-local regularization method can be used

(/NONLOCAL/MAT). In this case, the sum of the

deviatoric plastic strain

and volumetric plastic strain

is regularized and used for damage

evolution:

The regularized sum can be plotted using /ANIM/ELEM/NL_EPSP or /H3D/ELEM/NL_EPSP.