/MAT/LAW124 (CDPM2)

Block Format Keyword A concrete material law accounting for plasticity, damage, and strain rate effect.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW124/mat_ID/unit_ID or /MAT/CDPM2/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | IDEL | IRATE | FCUT | ||||||

| ECC | HP | ||||||||

| AH | BH | CH | DH | ||||||

| AS | BS | DF | DFLAG | DTYPE | IREG | ||||

| WF | WF1 | FT1 | EFC | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young’s

modulus. (Real) |

|

| Poisson’s

ratio. (Real) |

||

| IDEL | Element deletion flag.

(Integer) |

|

| IRATE | Rate dependency flag.

(Integer) |

|

| FCUT | Strain rate filtering

frequency. Default = 10 kHz (Real) |

|

| ECC | Eccentricity. Default in Comment 6 (Real) |

|

| Initial hardening. Default = 0.3 (Real) |

||

| Strength limit in

tension. (Real) |

||

| Strength limit in

compression. (Real) |

||

| HP | Hardening

modulus. (Real) |

|

| AH | Compressive damage 1st

ductility parameter. Default = 0.08 (Real) |

|

| BH | Compressive damage 2nd

ductility parameter. Default = 0.003 (Real) |

|

| CH | Compressive damage 3rd

ductility parameter. Default = 2.0 (Real) |

|

| DH | Compressive damage 4th

ductility parameter. Default = 1.0E-6 (Real) |

|

| AS | First ductility measure

parameter.4 Default = 15.0 (Real) |

|

| BS | Second ductility measure

parameter. Default = 1.0 (Real) |

|

| DF | Dilation coefficient. Default = 0.85 (Real) |

|

| DFLAG | Damage model type.

(Integer) |

|

| DTYPE | Tensile damage shape.

(Integer) |

|

| IREG | Regularization flag.

(Integer) |

|

| WF | Tensile inelastic

displacement/strain at failure. Dimension depends on IREG parameter value. 4 7 (Real) |

|

| WF1 | Tensile in elastic

displacement/strain at softening slope change (bilinear damage

only). Dimension depends on IREG parameter value. 4 Default = 0.15*WF (Real) |

|

| FT1 | Tensile strength at

WF1. Default = 0.3*FT (Real) |

|

| EFC | Compressive inelastic strain close

to failure. 8 Default = 1.0E-4 (Real) |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW124/1/1

Concrete CDPM2

# Init. dens.

2.3E-9

# E NU IDEL IRATE FCUT

28000 0.19 1 2 0

# ECC QH0 FT FC HP

0 0 3.5 33.6 0.5

# AH BH CH DH

0 0 0 0

# AS BS DF DFLAG DTYPE Ireg

0 0 0 1 1 1

# WF WF1 FT1 EFC

0.006 0 0 0.0005

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The CDPM2 material law is a user-friendly concrete material law,

which considers several phenomena. Only a few parameters are mandatory to

easily use this constitutive model. The mandatory physical parameters

are:

- Young’s modulus

- Poisson’s ration

- Tensile strength

- Compressive strength

- Tensile fracture energy

- (Optional) Compression fracture energy

- For this law, the elastic behavior is supposed to be isotropic. The

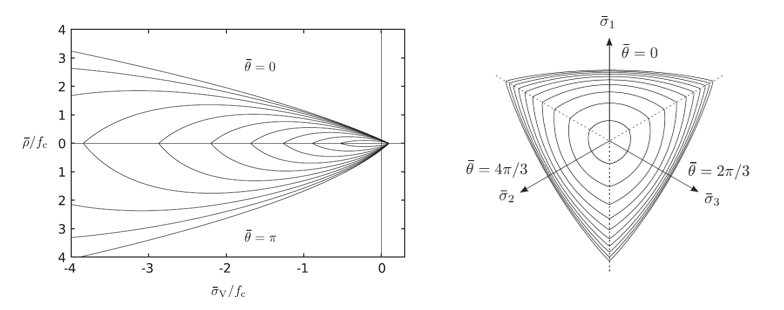

plastic behavior is then characterized by the following yield function

(Figure 1):

Where the Haigh-Westergaard coordinates in stresses space are considered:

, ,

Where,- Hardening variable

- Limit strength in compression

- Limit strength in tension

- A parameter considering the effect of eccentricity

Figure 1. CDPM2 model yield function shape (from Grassl)

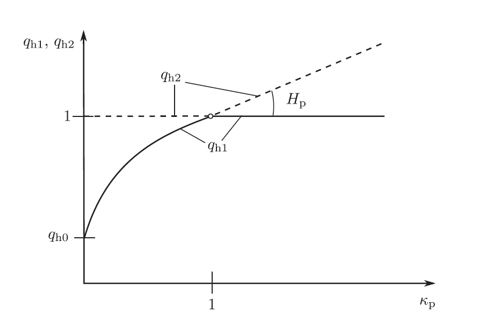

Then and are the two hardening functions defined with (Figure 2):Figure 2. Hardening functions shape (from Grassl)

Here, is the initial hardening defined so that . is the hardening modulus whose recommended value is 0.5. The evolution of the internal variable is detailed below.

The William-Warnke function is used to develop the deviatoric section shape between tension and compression (Figure 1).

- The plastic strain evolution is defined by a non-associated plastic

potential using the following equation:

With

Where, is the dilation parameter.

This plastic potential is used to compute the evolution of the plastic strain tensor and, thus, the evolution of the internal variable as:

with

Where, is the Euclidian norm of the increment of the plastic strain tensor.

- The CDPM2 model

considers an unsymmetrical damage evolution between tension and compression.

These variables are respectively denoted by

and

. The damage variables evolution is triggered

by a strain criterion defined by:When this criterion is reached, the damage history variables to the corresponding loading case (tension or compression) are updated:

- In Tension:

, , and

- In

Compression:

, and

With,

, , with

The inelastic strains can be obtained from damage history variable using the following equations:

and

The damage history variable finally enables to update the corresponding damage variables.

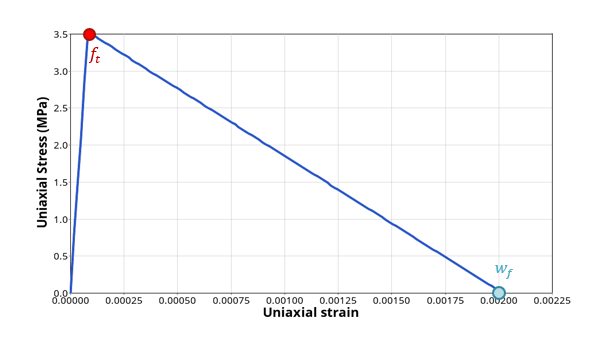

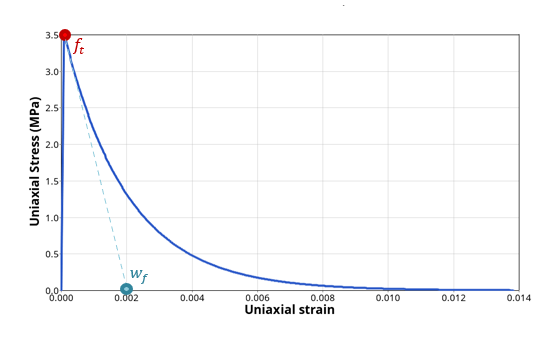

Regarding tensile damage, three different evolution shapes are available depending on the DTYPE parameter value:- DTYPE = 1: Linear damage

where

is the strength limit at the

beginning of damage, and

is the failure displacement for

which the stiffness becomes null (Figure 3).

Figure 3. Uniaxial tension test on a single unit element using linear damage evolution . with =3.5 MPa and =0.002 mm

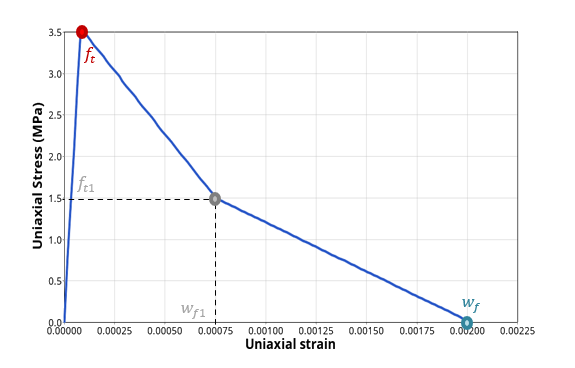

- DTYPE = 2: Bilinear damage

which is very similar to the linear damage apart from the use of

the couple of values

and

which define the coordinates of

the points where damage evolution changes its slope (Figure 4).

Figure 4. Uniaxial tension test on a single unit element using bilinear damage evolution . with =3.5 MPa, =1.5 MPa, =0.00075 mm and =0.002 mm

- DTYPE = 3: Exponential

damage where the displacement threshold

corresponds to the meeting point

between uniaxial strain axis, and tangent curve to the beginning

of stress softening (Figure 5).

Figure 5. Uniaxial tension test on a single unit element using exponential damage evolution . with =3.5 MPa and =0.002 mm

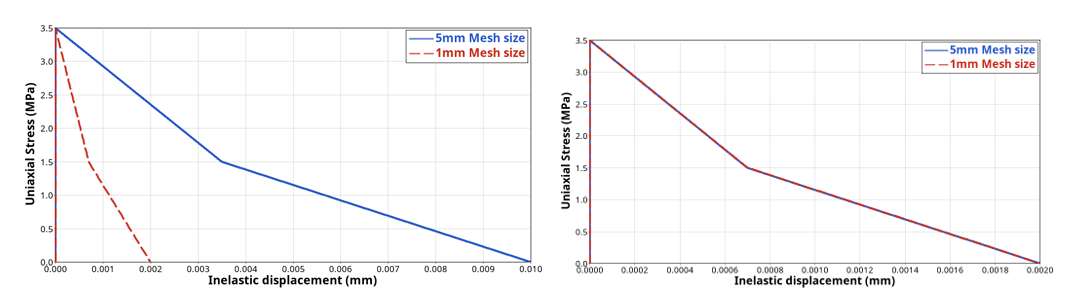

In these different equations, is a parameter that can be used to avoid mesh size dependency. When IREG = 1, no regularization method is used, and is set to 1. In that case, the critical value becomes a critical strain with no dimension. Otherwise, if IREG = 2, the Hillerborg’s regularization method 2 (also called Crack Brand method 3) is used, and equals the initial element size. Then, the critical value becomes a critical displacement homogeneous to a displacement. Hillerborg’s regularization method is to ensure that the tensile fracture energy denoted remains constant no matter what element size is used (Figure 6).Figure 6. Uniaxial tension test with bilinear damage on two different mesh sizes with IREQ = 0 (left); IREQ = 1 (right)

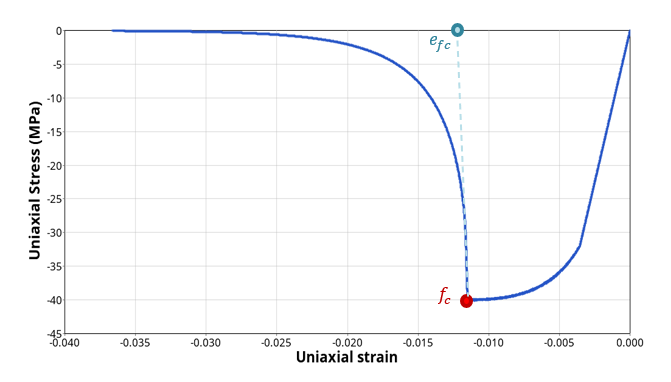

Regarding compression damage, only the exponential evolution shape is available without any regularization method (Figure 7). Mesh size dependency is assumed to be less sensitive.Figure 7. Uniaxial compression test on a single unit element . with

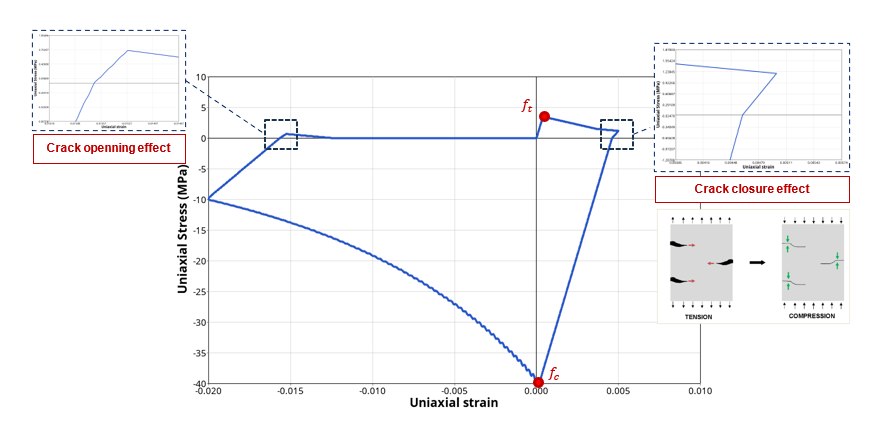

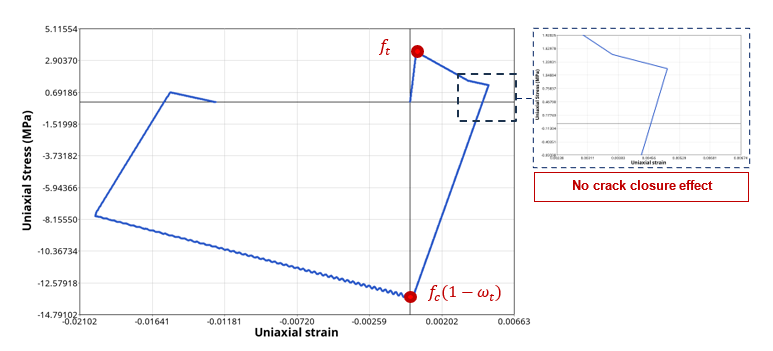

The effect of damage on stress computation will depend on the DFLAG parameter value:- DFLAG = 1: Non-symmetric

softening which considers the crack closure effect when

switching from tension to compression, recovering the initial

stiffness. On the opposite, a switch from tension to compression

re-opens the already existing cracks. (Figure 8).Where, and are respectively the tension and compression part of the undamaged (effective) stress tensor.

Figure 8. Loading/unloading uniaxial test with non-symmetrical damage softening

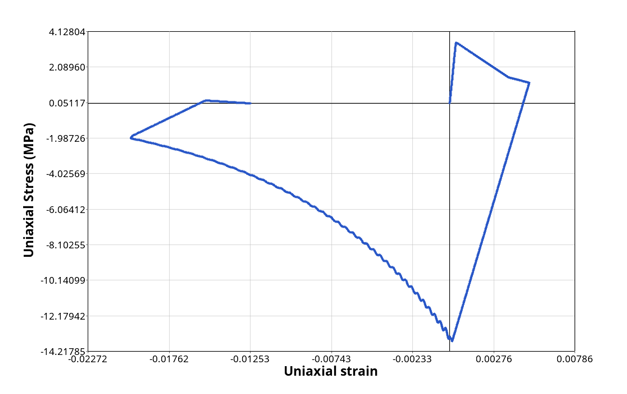

- DFLAG = 2: Isotropic

softening that considers only the effect of tensile damage in

both tension and compression. Then crack closure is not

considered. No changes of stiffness are observed when switching

from tension to compression or the opposite (Figure 9). Tensile damage is also

less likely to evolve in compression.

Figure 9. Loading/unloading uniaxial test with isotropic damage softening

- DFLAG = 3: Multiplicative

softening where the effect of both tension and compression

damage are considered and cumulated on the behavior (Figure 10).

Figure 10. Loading/unloading uniaxial test with multiplicative damage softening

- In Tension:

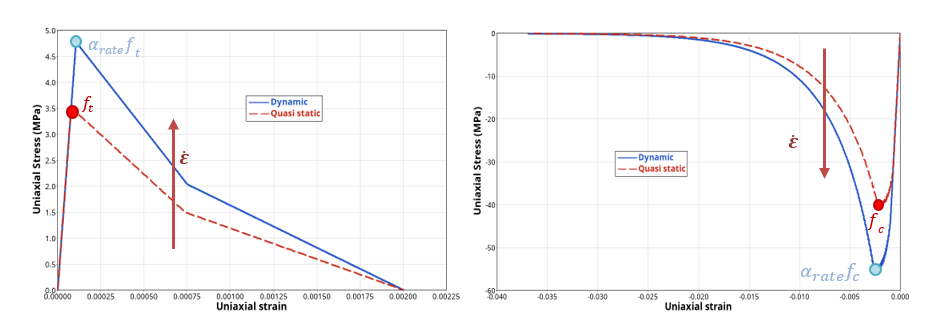

- The last phenomena considered by CDPM2 model is the strain rate

dependency. At a high strain rate, the concrete is more likely to have a

larger tension or compression strength limit. This is introduced by the

following equations:

, and

The dynamic increase factor (DIF) is computed with:

Where, is the compression factor defined above in damage history variables equations in Comment 4.

There is then a different strain rate dependency between tension and compression as concrete is more sensitive to strain rate effect in tension than in compression. The two dynamic increased factor for both tension and compression are computed with:

with ,

with ,

The equivalent deviatoric strain rate is used to compute the DIF in the equations above.

No parameters need to be identified for strain rate effect. You only need to set the flag IRATE to 2. Figure 11 shows the expected tendency of strain rate effect on the CDPM2 behavior. By increasing the strength limits in tension/compression, the dissipated energy during failure is also affected which is often observed experimentally.Figure 11. Uniaxial tests in tension/compression with strain rate dependency (IRATE = 1)

- Default value of

eccentricity can be obtained with:

and

- The tensile fracture

energy,

is not used directly as an input in the

model but is used to calculate the value of the tensile inelastic

displacement/strain at failure

.

For the linear softening law (DTYPE = 1), the tensile fracture energy is:

(if IREG = 2, default)

(if IREG = 1 with h= reference element size for identification)

For the bilinear softening law (DTYPE = 2), the tensile fracture energy is:

Suppose that = 0.3 and = 0.15, this leads to:

(if IREG = 2, default)

(if IREG = 1) with h = reference element size for identification)

- The compression

fracture energy,

is not used directly as an input in the

model but is used to calculate the value of the compressive inelastic strain

close to failure as:

with h= reference element size for identification and is the ductility measure:

- Global damage variable can be output using /ANIM/BRICK/DAMG or /H3D/SOLID/DAMG. Two modes of

damage can be plotted using MODE = I or

ALL:

- Mode 1: tension damage

- Mode 2: compression damage