Rattle Evaluation

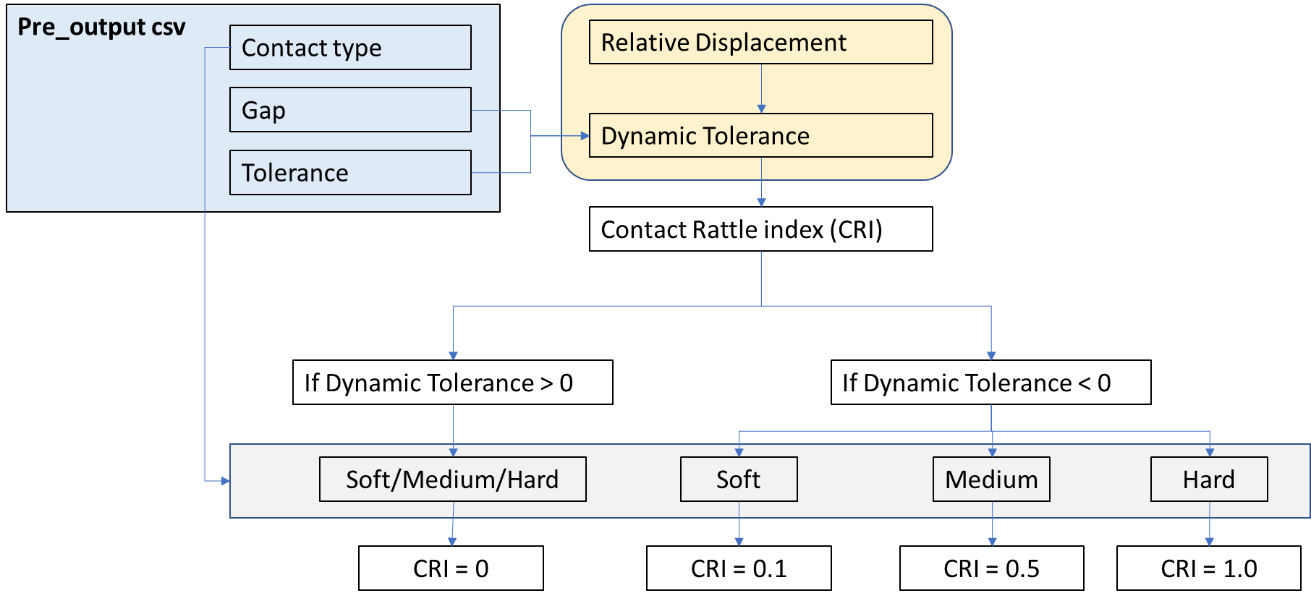

Rattle evaluation is based on the assessment of relative displacement between two parts along the defined E-Line. The relative displacement is compared to the gap and tolerance values defined during the pre-processing workflow.

- Relative displacement magnitude and in local Z-direction.

- Dynamic Tolerance is defined as:

Gap [mm] - Tolerance [mm] - Relative Dsiplacement in Z.

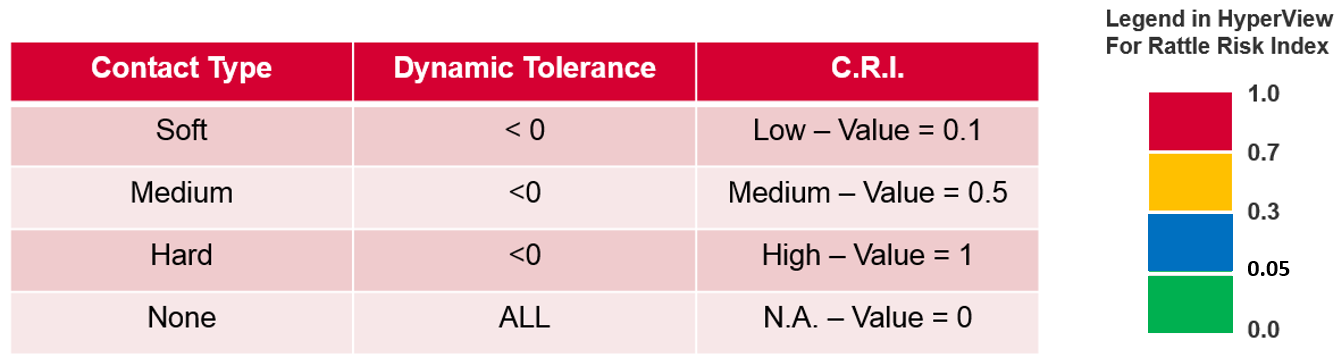

In addition, SnRD proposes an unit-less Contact Rattle Index (CRI) coupled to the material pair along the rattle E-Line. Named Contact Type, this criterion is based on material stiffness values.

Contact Types

- Soft: materials such as foam, leather and rubber- default Youngs(E) Modulus < 500 MPa

- Medium: soft plastics material- 501 MPa < E-modulus < 10000 MPa

- Hard: hard plastics, metals, glass materials- E-modulus > 10000 MPa

Figure 1.

Figure 1.

Figure 2. Contact Risk Index Matrix