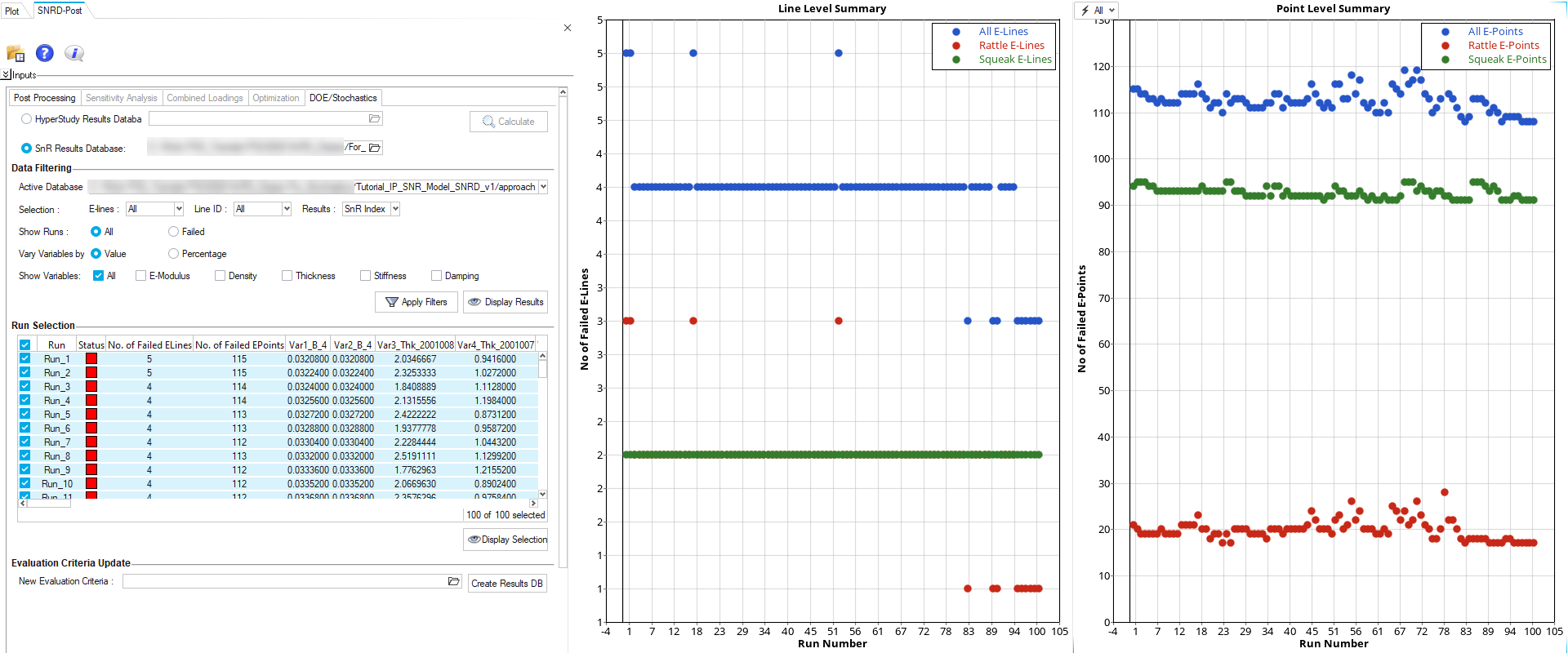

Variability (Stochastics) Study

Study the effects of parameter variations on squeak and rattle issues.

The manufacturing of parts is often related to variations of tolerances and quality of materials. Also, the assembly process adds a set of variations on dimensions and connection of stiffnesses resulting in a unique product at the end of each build. These two major processes contribute to the quality and performance of the final product.

squeak and rattle are phenomena that are tightly related to the quality of the built parts, and performance can vary through the population of produced products.

- Prepare the FE model for analyzing squeak and rattle issues.

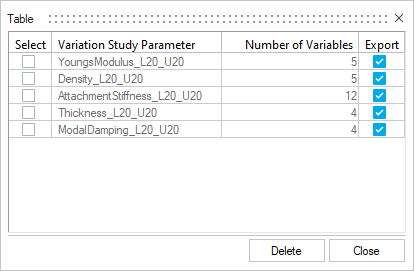

- Setup variability study for the following-

- Material Parameters

- Attachment Stiffness

- Thickness, and

- Damping

- Run analysis and post-process the results.

For this tutorial, you will use the solver deck exported from the Detailed Risk and Root Cause Analysis usecase. Once you import the Dynamic Loadcase solver deck, you can proceed with Variability (Stochastics) Study setup.

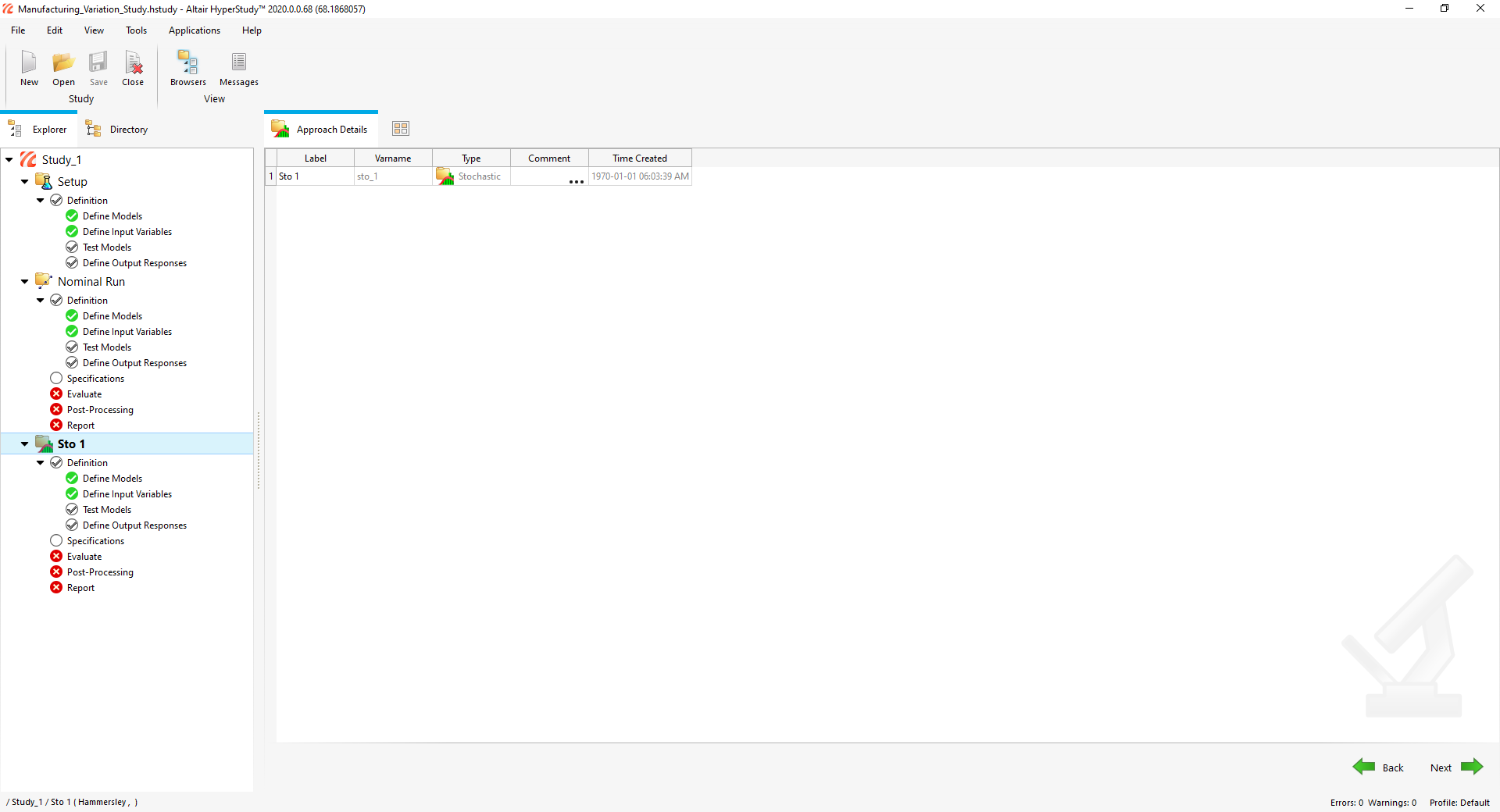

Variability Study Setup

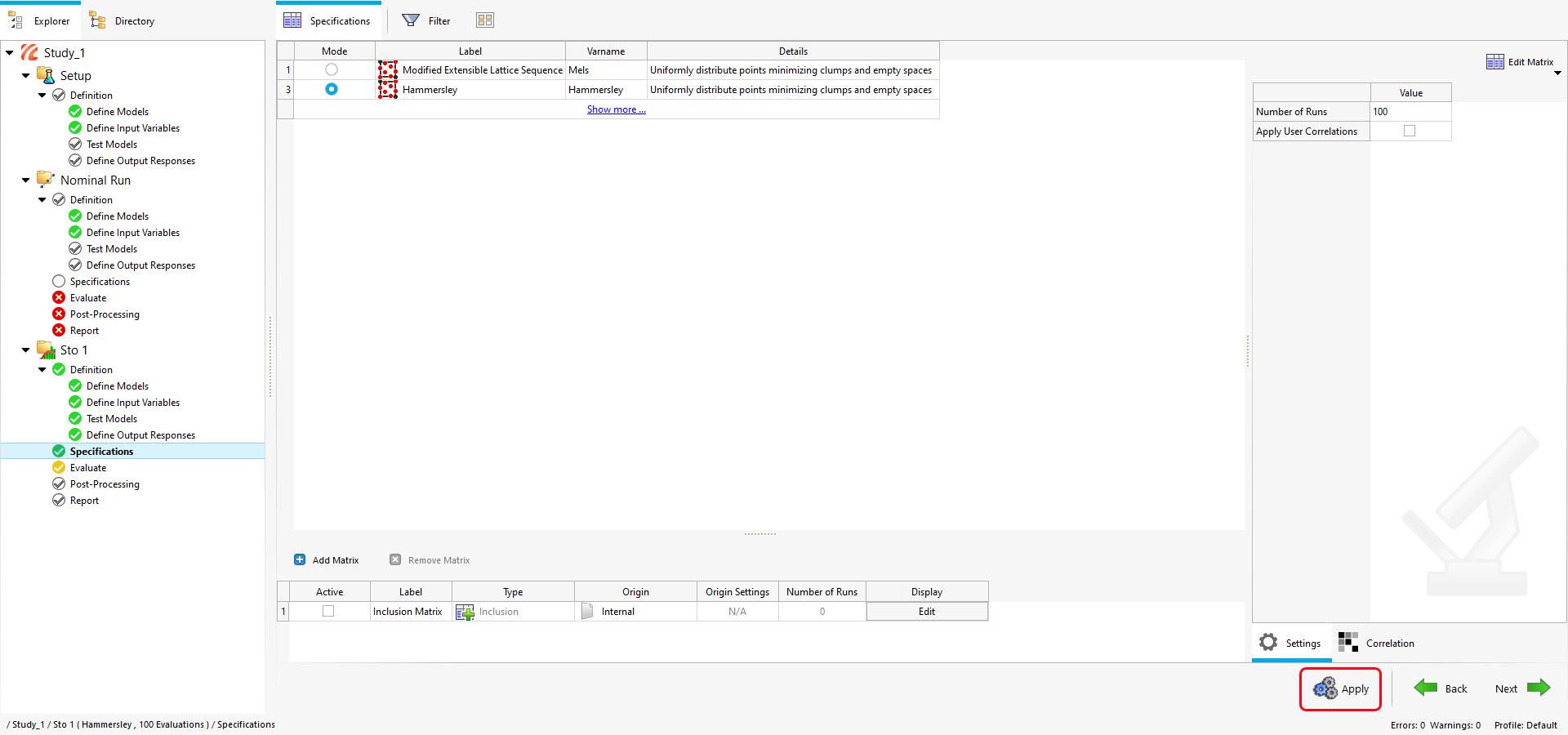

In this step, you will setup variability study(s).

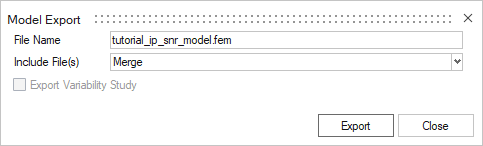

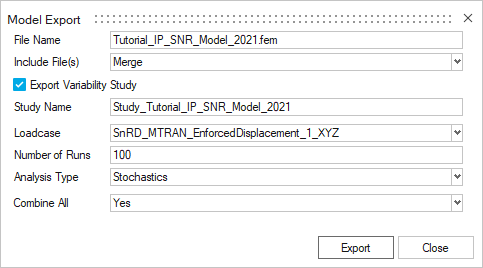

Export Solver Deck

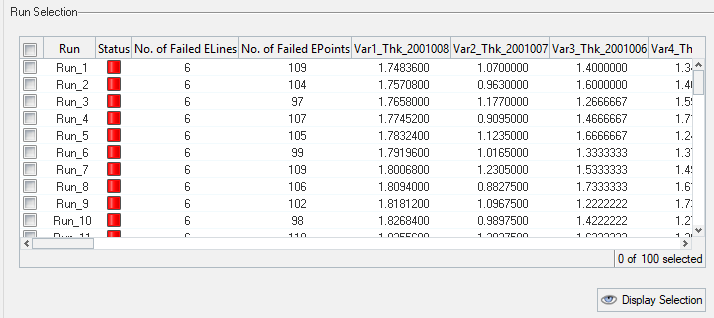

Conduct Stochastics Runs

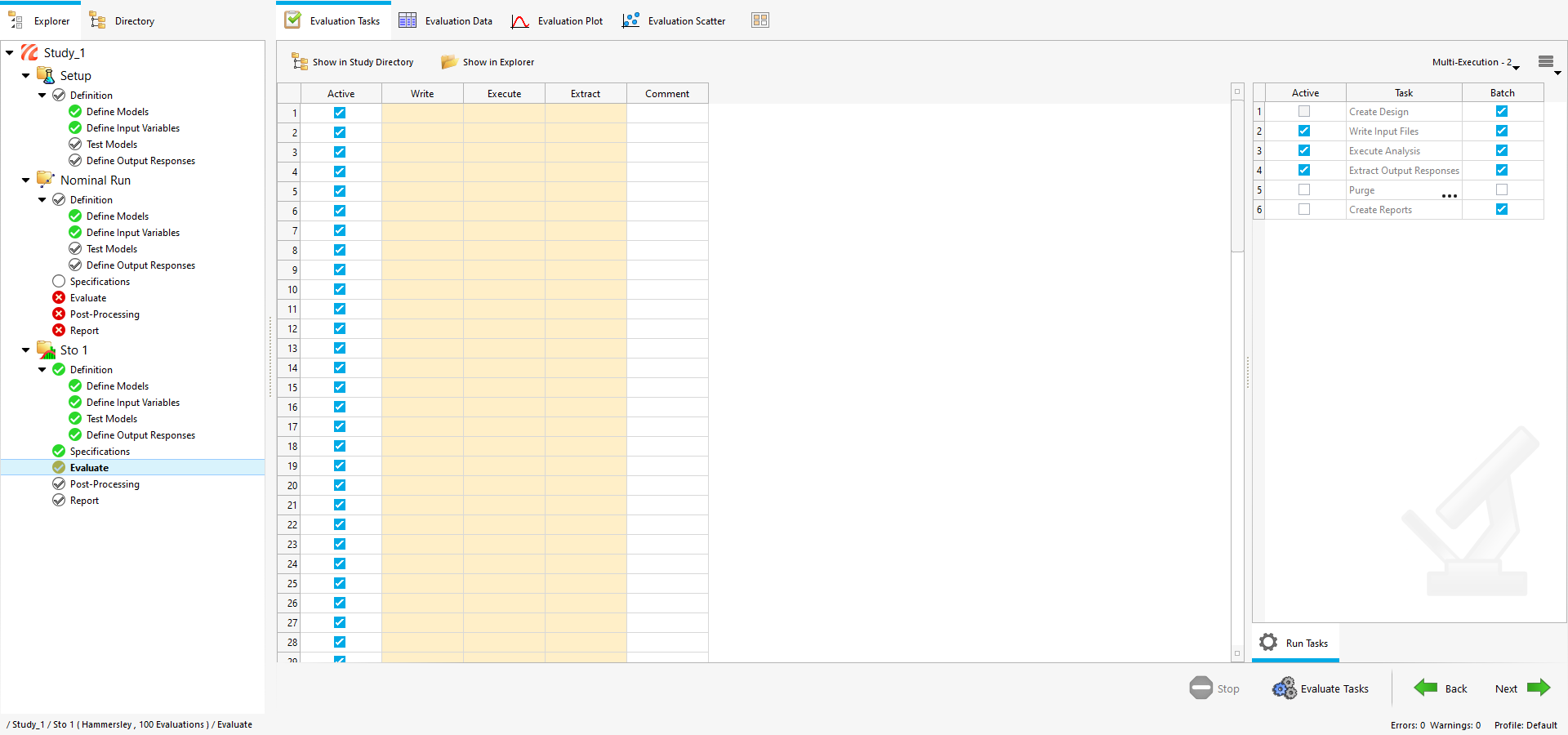

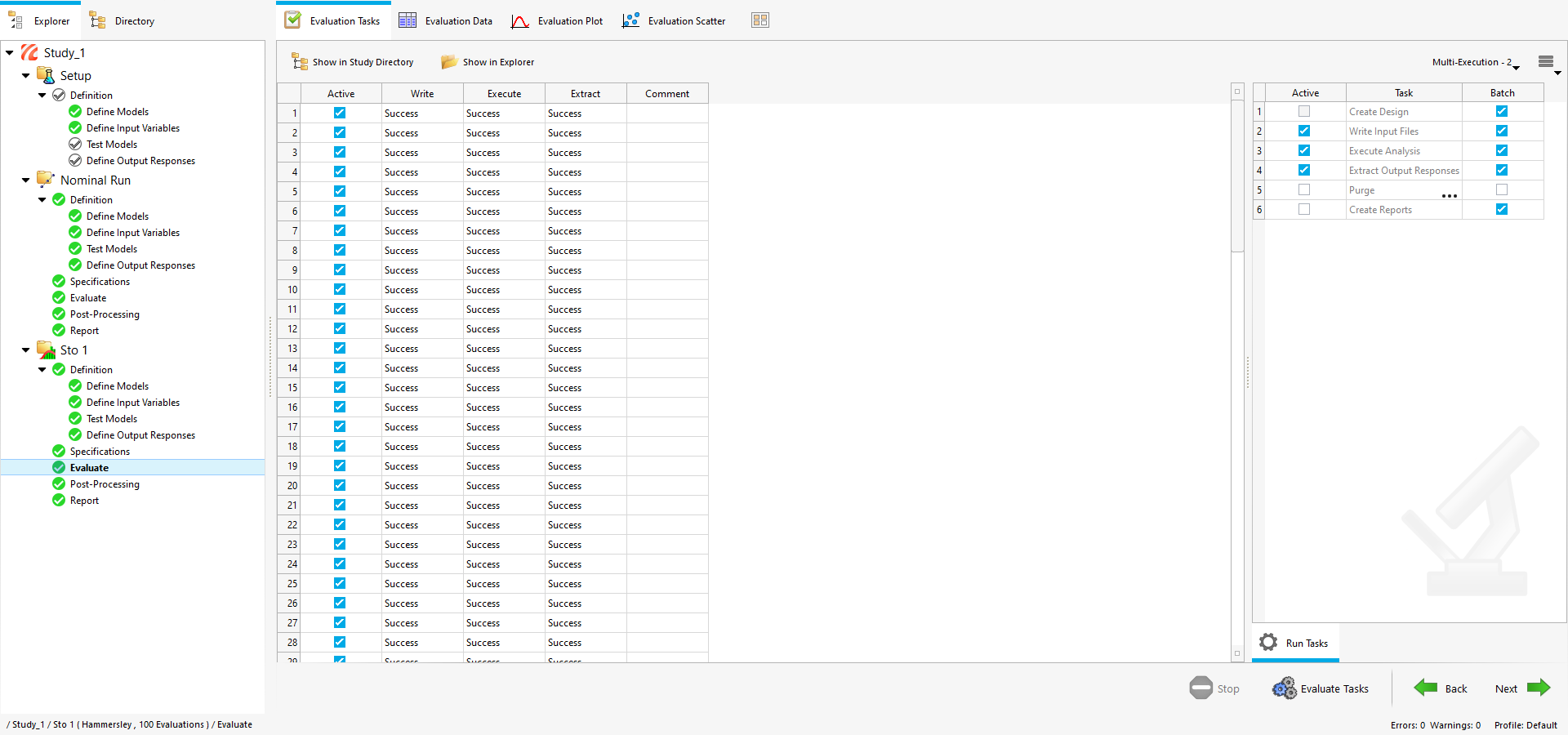

In this step, you will generate results database and summary files. These files will be later used in SnRD Post-processing.

- TPL

- XML

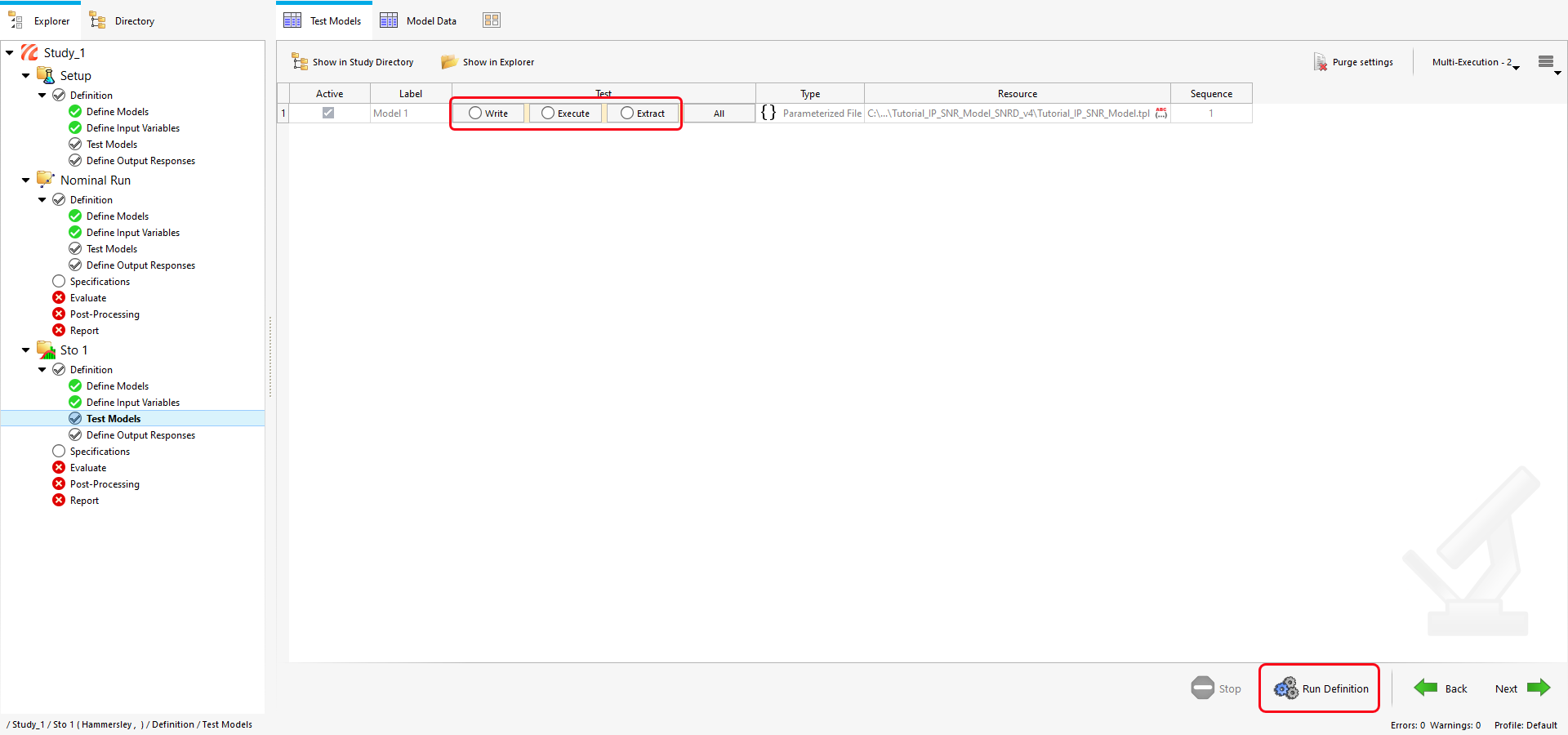

The template (TPL) file us created with the required parameters that are readable by HyperStudy.

and

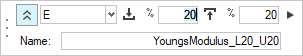

and  value fields.

value fields.

to expand the

to expand the

to proceed to the

to proceed to the