Post-Processing

Use the Show Analysis Results tool to view the results of an analysis in the Analysis Explorer. View and animate results, add callouts, and compare results from different runs.

Results must be available before attempting post-processing.

-

From the Extrusion ribbon, click

the Analysis tool.

Post-processing mode is activated. - Optional:

If you need a detailed analysis of results, use HyperView, which requires the appropriate license

features. Inspire's post-processing features are

adequate to analyze and understand the results.

Select Tool Deflection to view coupled analysis results.

Animate and Record Results

Use the Animation Toolbar that appears at the bottom of the modeling window to animate and record results.

Animate the Results

If you've previously run an analysis, click the Play button on the animation toolbar to animate the results.

-

Click the

button on the

animation toolbar to review the analysis. Click the

button on the

animation toolbar to review the analysis. Click the  button to pause

the animation.

button to pause

the animation.

- Optional:

Click the

icon to change the animation settings.

icon to change the animation settings.

- Right-click and mouse through the check mark to exit, or double-right-click.

Record the Results

Capture to a video in .mp4 format by clicking the ![]() button on the animation toolbar.

button on the animation toolbar.

- If you haven't already done so, play back your results to get an idea of what you're about to record.

- Optional:

If desired, click the

icon to change the animation settings.

icon to change the animation settings.

-

Click the

button on the animation toolbar to begin recording

the motion results; the icon changes to red to indicate that it is recording.

Click the icon again to stop recording.

button on the animation toolbar to begin recording

the motion results; the icon changes to red to indicate that it is recording.

Click the icon again to stop recording.

- When the recording is finished, the video is automatically saved in the C:\Users\<yourname>\Documents\Altair\videos directory. It is automatically given a name constructed from the time stamp, i.e. recording2018.8.8_15.47.39.mp4.

- Right-click to exit review mode.

- The default behavior is continuous recording, but the recording will stop automatically if the playback option is set to Once rather than Loop.

- To hide the workflow help, select , and in the Workspace category clear the Show workflow help checkbox.

- To avoid recording the mouse cursor, click the

button on the animation toolbar and press the

Tab key to move the focus to the

button on the animation toolbar and press the

Tab key to move the focus to the  button. Then press the Spacebar to start or

stop the recording.

button. Then press the Spacebar to start or

stop the recording. - Note that the video recorder captures everything in the region of the modeling window. Avoid obscuring or minimizing that window during the recording process.

Animation Options

The animation options allow you to start and stop the animation and adjust basic settings.

| Option | Description | |

|---|---|---|

| Play/Stop Animation |  |

Animate the selected result. |

| Animation Speed | Change the speed of the animation. | |

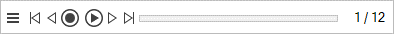

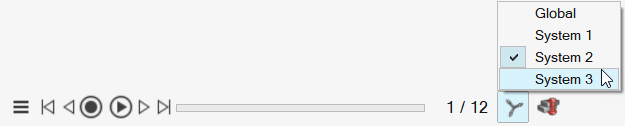

Animation Toolbar

Use the animation toolbar to play, record, and configure the animation.

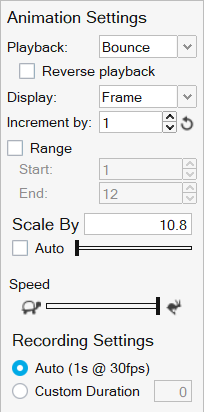

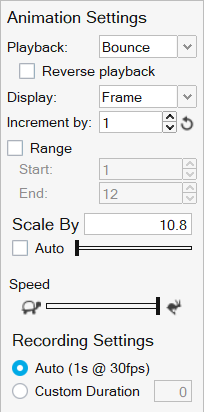

- Animation Settings

- Click to open the Animation Settings.

- Play and Record/Stop Recording

- Click the button to begin recording the results; the icon changes to red to indicate that it is recording. Click the icon again to stop recording.

- Start Animation/Pause Animation

- Click the button to start or pause the animation. Use the arrow buttons to jump the first or last frame in the animation.

- Move to First/Previous/Next/Last Step

- These buttons allow you to step through the animation frame-by-frame. If you hold down the Previous or Next button, it will auto-repeat. If you want to skip frames, use the Increment By feature in the Animation Settings; hold Ctrl to temporarily override this behavior.

- Slider

- Drag the slider on the toolbar to view a particular point during the analysis; use the arrow keys to move frame-by-frame through the animation.

- Current Step

- Displays the current time or frame. You can also enter a value to go to the nearest time/frame.

Animation Settings

Modify the animation settings from the animation toolbar.

- Playback

- Select whether to play the animation on a continuous Loop, Once, or Bounce (between forwards and backwards). Select the check box to Reverse Playback.

- Display

- Set the units for the slider to either Time or Frame.

- Increment By

- Increase the value in the counter to skip frames during playback. The reset button restores the default value of 1.

- Speed

- Drag the slider to change the speed of the animation.

- Range

- Select the Range checkbox to define and starting and ending frame for the

animation. This allows you to limit the playback range to just a portion of

the animation, making it easier to study behaviors in more detail. You can

use the Ctrl key while clicking on the Start or End icons to jump to Range

Start and Range End, respectively. Note: For motion models, you can fit plots for the selected range by using the Ctrl key while double-clicking. Also, the paths of tracers will be trimmed to honor the specified range.

- Scale Factor

- Enter a custom value to change the scale of the animation. Generally the scale of a displacement is too small to see clearly, so auto scaling is enabled by default.

- Recording Settings

- The default Auto setting gives you an estimate of the duration of the recording at 30 frames per second. If your video plays back faster than you want, select Custom Duration to change the length of the video; this will adjust the frame rate to try to achieve the specified duration. The Custom Duration has a minimum value of 1 second, and maximum value of 30 seconds.

Animation Shortcuts

| To | Do this |

|---|---|

| Play and pause | If the Play button is active, press the Spacebar. |

| Go to the first/last frame | Press the Home or End key. |

| Go to the next/previous frame | Press the Page Up or Page Down key. |

| Increment the slider |

Use the arrow keys to move frame-by-frame through the animation, or position the cursor over the slider and use the scroll wheel. |

| Exit tool | Right-click and mouse through the check mark to exit, or double-right-click. |

Result Types

| Option | Description |

|---|---|

| Displacement | The displacement plot gives a measure how much the nose cone has deformed. The displacements are computed from the velocities and these show how the profile nose-cone evolves. In addition, the displacements can be used to see if the profile meets dimensional tolerances. This result is qualitative and helps to determine if the die is well balanced. |

| Pressure | The pressure at the ram end provides the extrusion force required

to push the billet. This data also provides information on the

resulting extrusion loads on the die surfaces. This data is used to

predict tool deflection. Pressure in the weld chamber helps to create good welds. Weld strength is higher if the ratio of pressure to flow stress is higher in this region. Pressure also affects the friction in the bearing region. |

| Temperature | Flow stress of a material is a strong function of temperature

and strain rate. In addition, key material characteristics such as

grain size depend on temperature. Hence, understanding the

temperature distribution is the key to successful extrusion.

Temperature data is used to determine where excessive heating occurs in the die due to stress work. Temperature distribution in the profile region is used to determine the surface quality and other material characteristics. In the profile region, temperature variations of about 5% or less are acceptable. For high end applications, there are tighter tolerances. |

| Velocity | This data provides a detailed understanding of how material deforms and flows during extrusion. Using this data, we can detect flow imbalances at the die exit. In the case of multi-hole dies, we can determine how fast the profile is exiting from each hole and the resulting profile length during each cycle. Studying the material flow in die regions such as portholes and pockets can help redesign to improve the performance of the die. |

| Flow Stress | The flow stress of an alloy is a function of temperature, effective strain rate, and effective strain and describes how a material viscoplastically deforms during the process. This is a scalar result. The solver uses constitutive laws such as Sellars-Tegart, Metal Forming Power Law, and Hensel-Spittel models to compute the flow stress. You will find the details of these models in the Reference section. The local flow stress in comparison with the local pressure serves as a useful measure of weld stress in that region. It is also useful in understanding wear on contact surfaces and in modeling friction (viscoplastic friction laws). |

| Strain | The strain plot represents a measure of how the material is deforming and quantifies the change in the shape with respect to its original billet cross-section. |

| Strain Rate | The solver computes the effective strain rate based on the deformation tensor. This quantifies the rate at which the material is deforming. |

| Principal Stress | Shows the stresses acting on the meridional as a given point oriented along the principal direction where shear stress is zero. This helps identify critical stress points and is essential for evaluating the material failure. |

| von Mises Stress | The von Mises Stress is a scalar value used to predict yielding of materials under complex loading conditions. It combines the effects of all stress components into a single value, making it easier to evaluate whether the material will fail. |

| Maximum Shear Stress | Maximum Shear Stress results are computed by the post-processor

and not directly by the solver. The post-processor takes the stress

tensor data (output from the solver) and calculates the maximum

shear stress using the formula below. Maximum Shear Stress refers to the highest shear stress experienced by the material during the extrusion process. It is critical for evaluating material flow, identifying regions prone to defects like tearing or cracking, and ensuring smooth extrusion. On the tool side, maximum shear stress indicates the highest shear forces exerted by the aluminum on the tool assembly. |

| Temperature Compensated Strain Rate | The Temperature Compensated Strain Rate combines strain rate and temperature effects on material deformation, usually expressed through the Zener–Hollomon parameter. It enables comparison of flow stress across different test conditions by accounting for the influence of temperature, providing a single effective measure of deformation severity. At high

temperature, deformation is easier; at a higher strain rate,

deformation is harder. This can be expressed using Zener

-Holloman parameter. where

This parameter compensates the strain rate for temperature, hence the name temperature-compensated strain rate. A higher temperature compensated strain rate means higher effective deformation severity (high strain rate or low temperature). A lower temperature compensated strain rate means easier deformation (lower strain rate or high temperatures). Z is typically very large in magnitude (can go up to 1020 or more depending on temperature and strain rate). That's why, instead of reporting Z directly, the solver writes its natural logarithm value. This keeps the numbers in a readable range like 30 to 50 and also makes it easier to visualize the correlation between flow stress and deformation conditions. |

| Billet Interface | The HyperXtrude solver calculates the transverse or charge weld

length during billet-on-billet extrusion. This requires running a

transient analysis. Extrusion is a cyclic process. After the first billet is extruded, the butt is sheared, and a new billet is put in place. The material inside the die gets displaced by the new billet during the new billet cycle. Hence, the front portion of the extruded part will have a mixture of both new and old billet material. This region is weak and discarded as scrap. Billet Interface contour helps in tracking how and when the profile will have 100% new material. By redesigning portholes and weld chamber, this scrap can be reduced. |

| Billet Skin | The HyperXtrude solver predicts how the impurities on the billet

skin migrate into the profile. This requires running a transient

analysis. The billet skin can get into the profile in two ways:

|

| Yield Stress | Yield stress is calculated from the grain diameters at the die exit. |

| Grain Size |

For advanced applications like automotive and aerospace, it is very important to control grain structure. Uniform and small grain structure leads to higher product strength. Grain size distribution depends on various process parameters, alloy, and die design. Grain size contour represents how the re-crystallization occurs during the extrusion. |

| Relative Exit Speed Difference | This data directly correlates to whether the extrusion is balanced or not. The values are a relative percentage difference of local speed compared to average extrusion speed. Hence, a value close to zero means the extrusion die is balanced, and higher percentage values mean there are greater imbalances in die. Depending on end applications, a die with a relative speed difference of 10 % or less is considered satisfactory. If end applications have tighter geometry tolerances, such as in automotive or aerospace, the limits are typically less than 3%. |

| Weld Strength Quality | The quality of the welding depends on many variables:

|

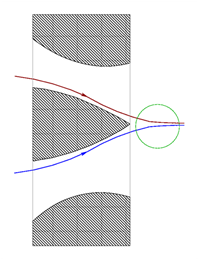

| Weld Surface | During extrusion of a hollow profile using bridge dies, the

billet splits and flows into the portholes before merging inside the

weld chamber. The surface formed when streams from neighboring

portholes merge is called the longitudinal seam weld.  The visualization of each surface region is shown in a different color. |