Create a Die

Use these tools to create solid profile dies for metal extrusion.

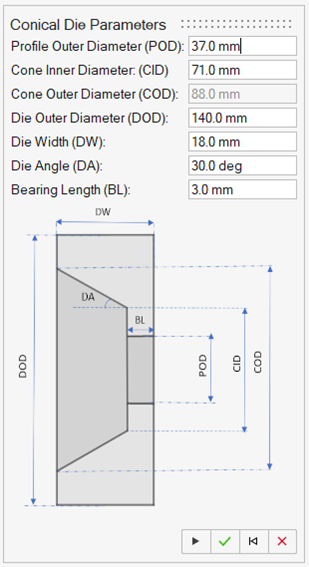

Create a Conical Die

Use the Die tool to create a conical die with custom dimensions to extrude a solid profile with a circular cross-section.

-

From the Extrusion ribbon, click the Die icon, and select Conical

Die from the drop-down menu.

This die is used to extrude a solid profile with a circular cross-section.

-

In the dialog, specify the geometric parameters for the die to be created.

The die nomenclature used is provided in the reference image at the bottom of the dialog.

- Profile Outer Diameter is the outer diameter of the extruded profile.

- Cone Inner Diameter and Cone Outer Diameter are the inner and outer diameters of the cone, respectively.

- The die Outer Diameter is the total diameter of the cylindrical die.

- Die Width will be the total width of the die cylinder. It includes both the conical region and the bearing region.

- Die Angle is the half-cone angle of the die.

- Bearing Length is the maximum length of contact between the material being extruded and the die.

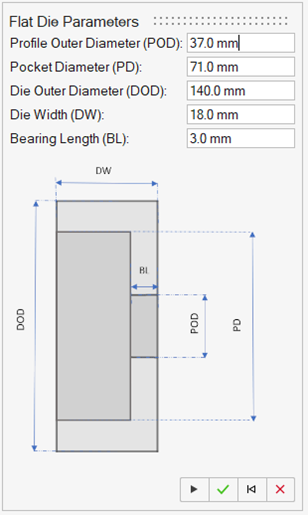

Create a Flat Die

Use the Die tool to create a flat die with custom dimensions to extrude a solid profile with a circular cross-section.

-

From the Extrusion ribbon, click the Die icon, and select Flat

Die from the drop-down menu.

This die is used to extrude a solid profile with a circular cross-section.

-

In the dialog, specify the geometric parameters for the die to be created.

The die nomenclature used is provided in the reference image at the bottom of the dialog.

- Profile Outer Diameter is the outer diameter of the material extruded.

- Pocket Diameter is the diameter of the pocket chamber.

- Die Outer Diameter is the total diameter of the die cylinder.

- Die Width will be the total width of the die cylinder.

- Bearing Length is the length of contact between the material being extruded and the die.

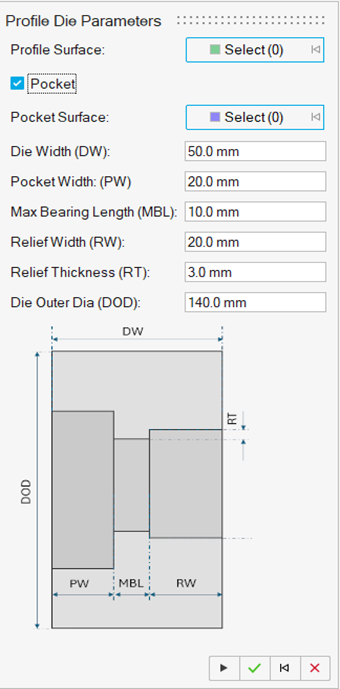

Create a Profile Die

Use the Profile Die tool to create dies that will extrude solid multi-hole profiles with pockets.

-

From the Extrusion ribbon, click the Die icon, and select Profile

Die from the drop-down menu.

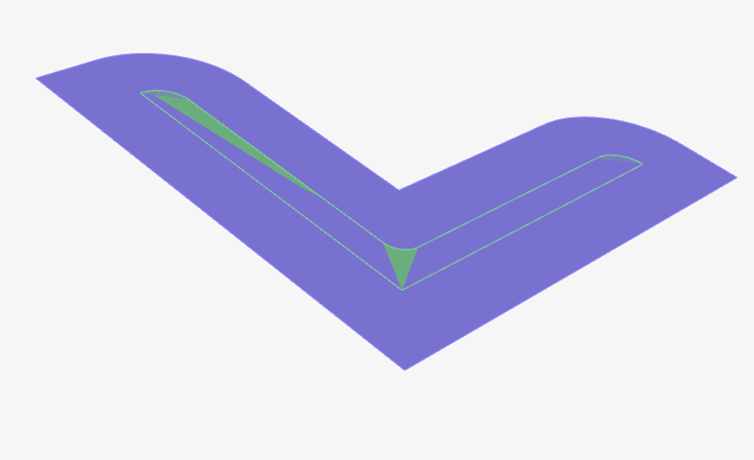

This die is used to extrude a solid profile with any cross-section. It can be used to create a single-hole or multi-hole die. These dies can be created with or without pockets.

-

In the dialog, specify the geometric parameters for the die to be created.

The die nomenclature used is provided in the reference image at the bottom of the dialog.

-

Use the surface selector button to select the custom pocket and profile

surfaces for the die.

Note: The input pocket and profile surfaces must be on the same plane. The profile surfaces should be contained within the limits of the pocket surface.

- Die Width is the total width of the die cylinder.

- Pocket Width is the width of the pocket chamber.

- Max Bearing Length is the maximum length of contact between the material being extruded and the die.

- Relief Thickness is a clearance provided after the bearing region.

- Relief width is the total width of this relief region.

- Die Outer Diameter is the total diameter of the die cylinder.

Profile dies can be created even without the Pocket region. To create a die without the pocket region, deselect the Pocket checkbox.