Finding Optimized Process Parameters

Determine process parameters to produce optimal results for surface quality and die life.

Inspire Extrude imports user data from the given model and uses the limits of the press and surface quality to determine the optimized billet temperature, ram speed, and billet taper, which you can import into the analysis process parameters.

-

From the Calibration ribbon, click the

Optimize tool in the Run

group.

The Optimized process parameters dialog is displayed.

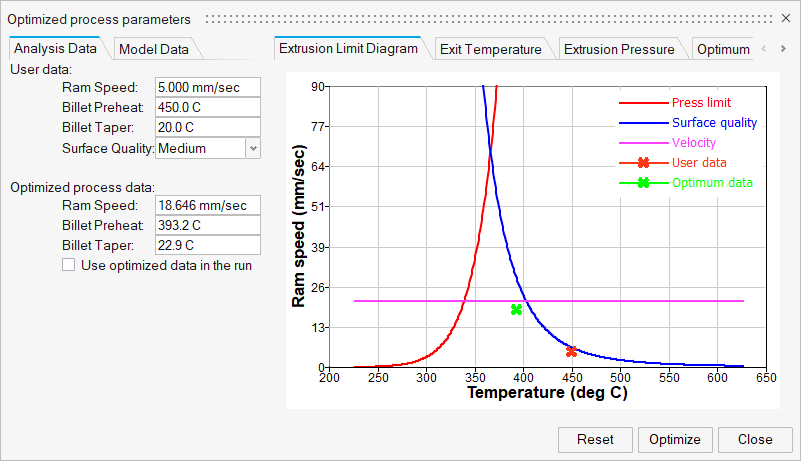

The Analysis Data tab contains User data and Optimized process data,

The Optimized process data section shows recommended process conditions for Ram Speed, Billet Preheat, and Billet Taper.

The Extrusion Limit Diagram tab shows graphically the optimum region between the curves of the Press limit and Surface quality and the upper limit of the maximum Velocity for the press. The User data represents the current model setup, and the Optimum data shows the improved result using the Optimized process data.

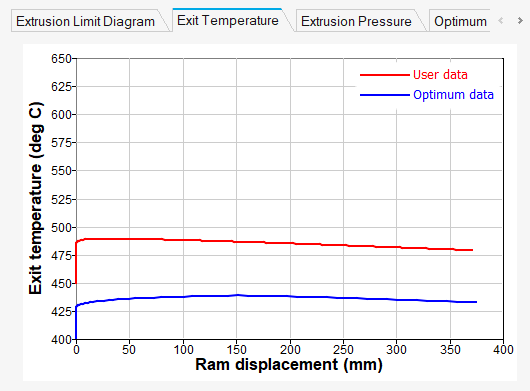

The Exit Temperature tab shows exit temperature curves for the user data and the optimized data.

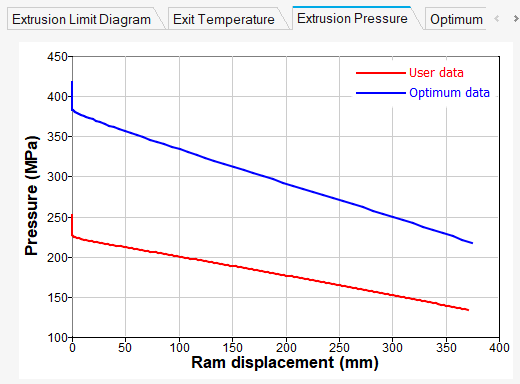

The Extrusion Pressure tab shows pressure curves for the user data and the optimized data.

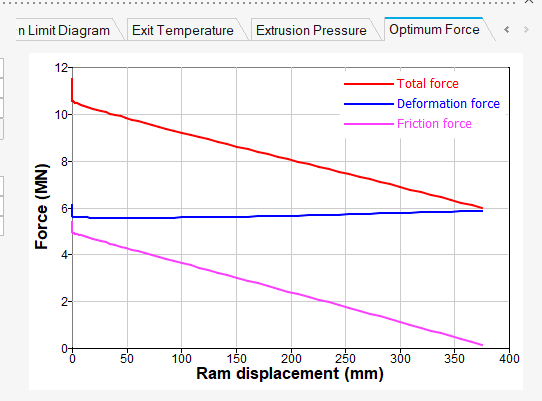

The Optimum Force tab shows deformation, friction, and total force curves.

- Optional:

Make changes to the Model Data, and run the

Optimize tool again.

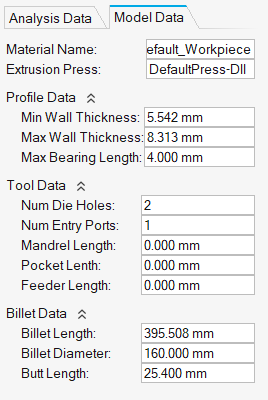

The Model Data tab contains information about the model, including the Material Name and Extrusion Press, as well as Profile Data, Tool Data, and Billet Data estimated from the model. You can adjust the data here and click Optimize to recalculate based on these new values. Click Reset to revert the data to the original estimated values.

-

Select Use optimized data in the run on the

Analysis Data tab to automatically populate

Analysis Parameters for a simulation with the

recommended optimal values for Ram Speed and

Billet Preheat.

Note: A recommendation for Billet Taper is given but not implemented. Click the Billet Taper tool, under the Process Data tool, to redefine the billet taper using the recommendation.