Milling

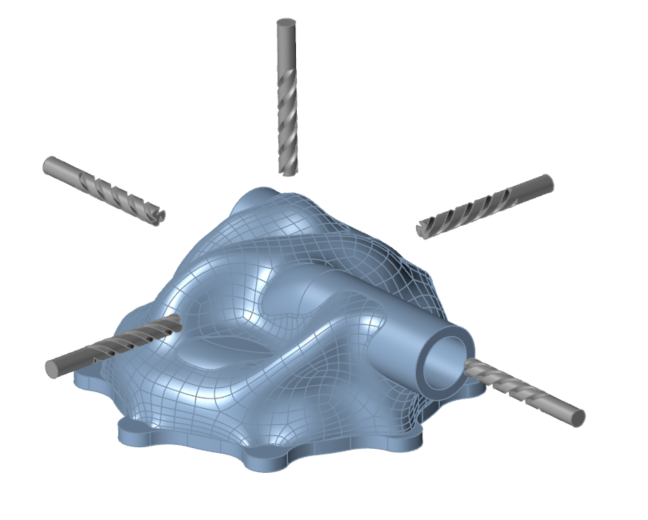

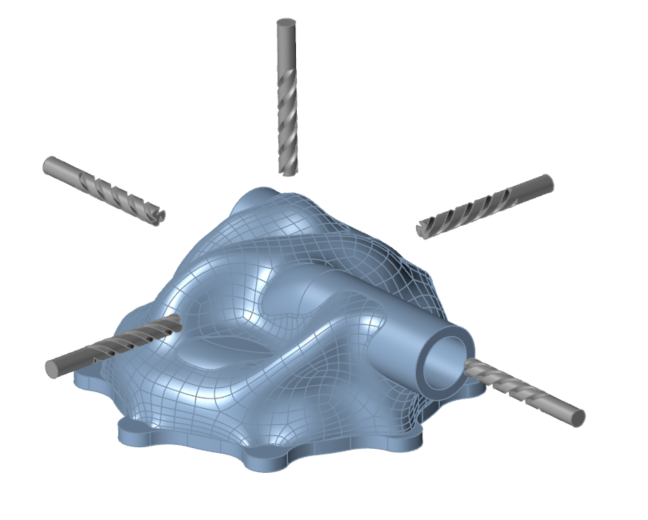

Apply a 5-axis milling constraint when a 5-axis milling machine will be used.

“5-axis” refers to the number of directions in which the cutting tool can move. On a

5-axis machining center, the cutting tool not only moves along the x, y, and z linear

axes, but also rotates about the x- and z-axes. This allows the tool to approach the

workpiece from any direction, allowing complex shapes to be machined. The geometry that

can be machined is constrained by the tool dimensions and subsequent machining access.

The access angle or tool dimensions must also be defined.

Apply a 5-Axis Milling Constraint

Apply a spherical draw direction, used when a machining tool needs a center of a sphere to remove material.

-

On the Structure ribbon, select the Draw Direction tool

on the Shape Controls icon.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

Select the Milling tool on the secondary ribbon.

-

Click a design space to apply a 5-axis milling constraint to one or more parts

of interest.

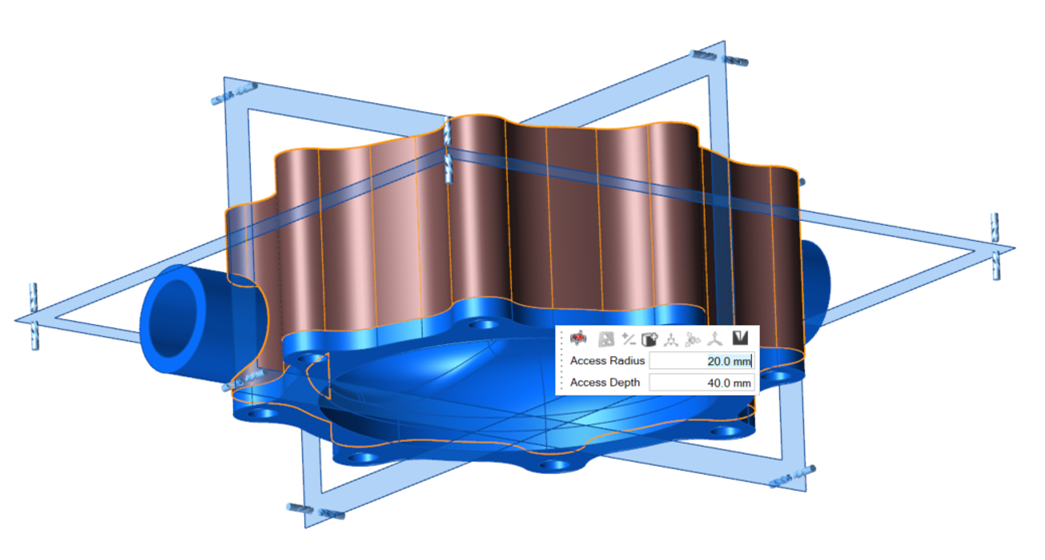

A microdialog appears, along with a set of three blue orthogonal planes.

-

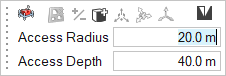

You can define the tooling dimensions by selecting either Access

Angle Parameters or Drill Bill Diameters

from the rightmost dropdown in the microdialog:

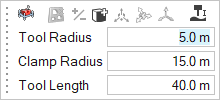

- Access Angle Parameters: Define the access angle

by defining the Access Radius and the

Access Depth, where the angle is r/d.

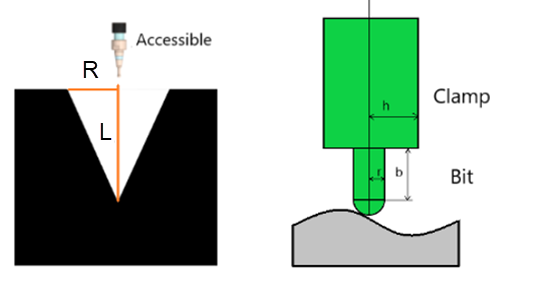

- Drill Bill Diameters: Define the dimensions of

the milling bit and head by entering the Tool

Radius, Tool Length, and

Clamp Radius.

- Access Angle Parameters: Define the access angle

by defining the Access Radius and the

Access Depth, where the angle is r/d.

- Optional:

Click Obstacles

on the microdialog to designate parts as obstacles

for the machining. These parts will prevent tool access through them.

For more information, see Obstacles.

on the microdialog to designate parts as obstacles

for the machining. These parts will prevent tool access through them.

For more information, see Obstacles. - Right-click and mouse through the check mark to exit, or double-right-click.

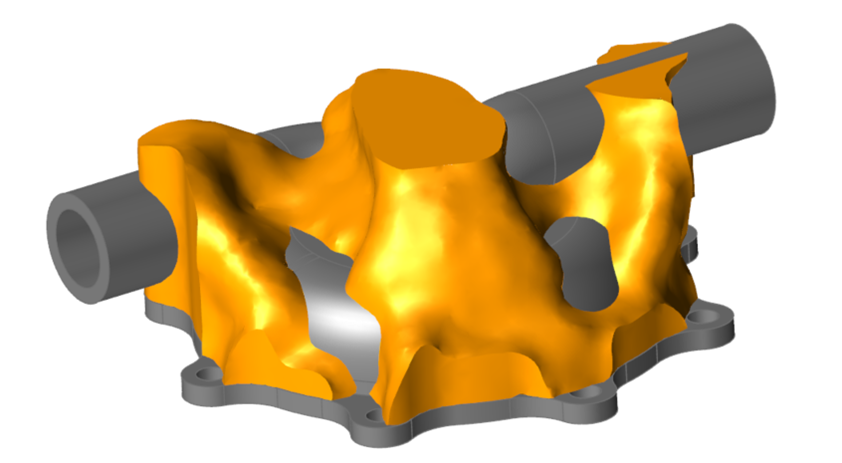

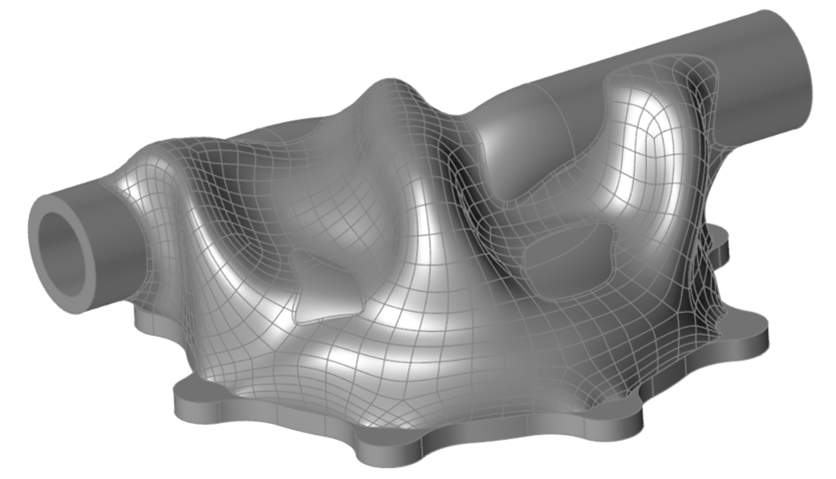

Milling Examples

Pumping Housing Optimization