/PROP/TYPE11 (SH_SANDW)

Block Format Keyword This property set is used to define the sandwich shell property set. It is possible to define sandwich composite with several layers and each lay with individual material, thickness, layer position and orthotropic direction.

This property is compatible with XFEM (crack propagation) using /FAIL/JOHNSON, /FAIL/TAB1 and /FAIL/TBUTCHER.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /PROP/TYPE11/prop_ID/unit_ID or /PROP/SH_SANDW/prop_ID/unit_ID | |||||||||

| prop_title | |||||||||

| Ishell | Ismstr | Ish3n | Idrill | P_thickfail | |||||

| hm | hf | hr | dm | dn | |||||

| N | Thick | Ashear | Ithick | Iplas | |||||

| VX | VY | VZ | skew_ID | Iorth | Ipos | IP | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| ti | Zi | mat_IDi | F_weighti | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| prop_ID | Property

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| prop_title | Property

title. (Character, maximum 100 characters) |

|

| Ishell | Shell element formulation

flag. 1

(Integer) |

|

| Ismstr | Shell small strain

formulation flag. 2

(Integer) |

|

| Ish3n | 3 node shell element

formulation flag.

(Integer) |

|

| Idrill | Drilling degree of freedom

stiffness flag. 7

(Integer) |

|

| P_thickfail | Fraction of failed

thickness for shell element deletion. 11

(Real) Default = 1.0 (Real) |

|

| hm | Shell membrane hourglass

coefficient. Default = 0.01 Default = 0.1 for hourglass type 3 (Ishell =3) (Real) |

|

| hf | Shell out-of-plane

hourglass. Default = 0.01 (Real) |

|

| hr | Shell rotation hourglass

coefficient. Default = 0.01 Default = 0.1 for hourglass type 3 (Ishell =3) (Real) |

|

| dm | Shell Membrane Damping. Default = 0.0 Default = 0.015 for Ishell =24 (QEPH)+LAW 27 Default = 0.05 for Ishell =1,2,3,4,12+LAW25 and 27 Default = 0.05 for LAW65 (Real) |

|

| dn | Shell numerical damping.

4 It only used for Ishell =12 and 24 Default = 0.015 for Ishell =24 (QEPH) Default = 0.001 for Ishell =12 (QBAT) Default =0.0001 for Ish3n =30 (DKT18) (Real) |

|

| N | Number of layers, with 1 ≤

N ≤ 100. Default = 1 (Integer) |

|

| Thick | Shell thickness. 9 (Real) |

|

| Ashear | Shear factor. Default is Reissner value: 5/6 (Real) |

|

| Ithick | Shell resultant stresses

calculation flag.

(Integer) |

|

| Iplas | Shell plane stress

plasticity flag.

(Integer) |

|

| VX | X component for reference

vector. Default = 1.0 (Real) |

|

| VY | Y component for reference

vector. Default = 0.0 (Real) |

|

| VZ | Z component for reference

vector. Default = 0.0 (Real) |

|

| skew_ID | Skew identifier for

reference vector. 8 Default = 0 (Integer) |

|

| Iorth | Orthotropic system

formulation flag for reference vector.

(Integer) |

|

| Ipos | Layer positioning flag for

reference vector. 9

(Integer) |

|

| IP | Reference direction in

shell plane. 8

(Integer) |

|

| Angle for layer

i. 8 (Real) |

||

| ti | Thickness of layer

i. 9 (Real) |

|

| Zi | Z position of layer

I

(Zi defines

the position of the middle of the layer). Default = 0.0 (Real) |

|

| mat_IDi | Material identifier for

layer i. 10 (Integer) |

|

| F_weighti | Relative failure weight

factor for layer i. Default = 1.0 (Real) |

Example

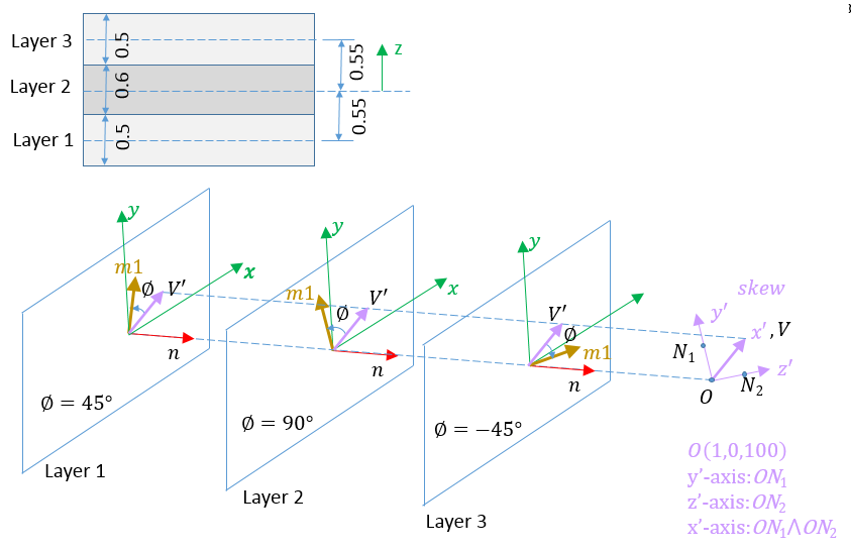

Figure 1.

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. LOCAL_UNIT_SYSTEm:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/2

unit for prop

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/SKEW/FIX/1

New SKEW 1

# OX OY OZ

1.0 0 100.0

# X1 Y1 Z1

0 0 1

# X2 Y2 Z2

0 -1 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. GEOMETRICAL SETS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SH_SANDW/2/2

SH_SANDW example

# Ishell Ismstr Ish3n Idrill Pthick_fail

12 0 0 0 0

# hm hf hr dm dn

0 0 0 .1 .1

# N Thick Ashear Ithick Iplas

3 1.6 0 1 1

# Vx Vy Vz skew_ID Iorth Ipos Ip

0 0 0 1 0 0 0

# Phi t Z mat_ID F_weighti

45 .5 0 1 0

90 .6 0 2 0

-45 .5 0 1 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

-

Ishell, Ish3n – 4-node and 3-node

shell formulation flag

- Ishell=1,2,3,4 (Q4): original 4 nodes Radioss shell with hourglass perturbation stabilization.

- Ishell=24 (QEPH): formulation with hourglass physical stabilization for general use (istotropic + LAW25 shells only).

- Ishell=12 (QBAT): modified BATOZ Q4γ24 shell with four Gauss integration points and reduced integration for in-plane shear. No hourglass control is needed for this shell.

- Ish3n=30 (DKT18): BATOZ DKT18 thin shell with three Hammer integration points.

- Ismstr- Small strain

formulation

- Small strain formulation is activated from time t = 0, if Ismstr =1 or 3. It may be used for a faster preliminary analysis, but the accuracy of results is not ensured. Any shell for which can be switched to a small strain formulation by Radioss Engine option /DT/SHELL/CST, except if Ismstr =4.

- If Ismstr =1 or 3, the strains and stresses which are given in material laws are engineering strains and stresses; otherwise they are true strains and stresses.

- hm, hf, and hr - Hourglass coefficients

- hm, hf, and hr are only used for Q4 shells. They must have a value between 0 and 0.05.

- For Ishell=3, default values of hm and hr are 0.1 with larger values possible.

- dn - Shell

numerical damping coefficient

- dn is only used for Ishell =

12 and 24.

- for Ishell = 24 (QEPH), dn is used for hourglass stress calculation

- for Ishell= 12 (QBAT), dn is used for all stress terms, except transverse shear

- for Ish3n=30 (DKT18), dn is only used for membrane

- dn is only used for Ishell =

12 and 24.

- Ithick- Shell resultant

stresses calculation flag

- If Ithick=1, the small strain option is automatically deactivated in the corresponding type of element.

- Iplas- Shell plane stress

plasticity flag

- It is recommended to use Iplas =1, if Ithick =1.

- Iplas=1 is available for Material Law 27.

- If Iplas=1, the small strain option is automatically deactivated in the corresponding type of element.

- Idrill - Drilling degree of freedom stiffness flag

- Drilling DOF stiffness is recommended for implicit solutions especially for Riks method and bending dominated problems.

- Idrill is available for QEPH, QBAT (Ishell =12, 24), and standard triangle (C0) shell elements (Ish3n = 1, 2).

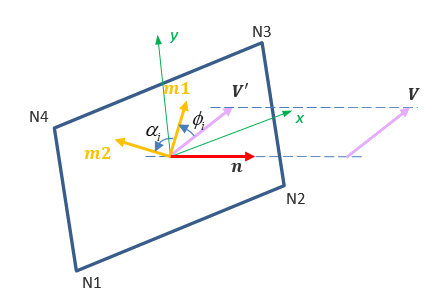

- Anisotropy direction

definition.The reference vector is projection of the input vector on the shell element surface and defined as following according to the flag IP:

- If IP=0 and skew_ID = 0, the vector is defined with VX, VY and VZ.

- If IP=0 and skew_ID ≠ 0, the vector is the first direction (local X) of the local coordinate system skew_ID.

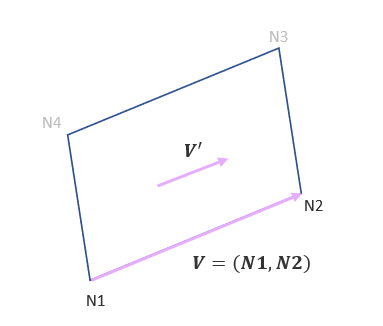

- If IP = 20, the vector

is defined with the node N1 and N2

of the shell elements.

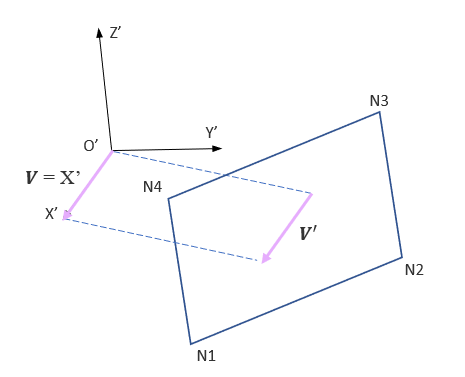

Figure 2. IP = 20 - If IP = 22, the vector

is the first direction (local X) of

the local coordinate system skew_ID. Vector

components VX, VY and VZ are ignored.

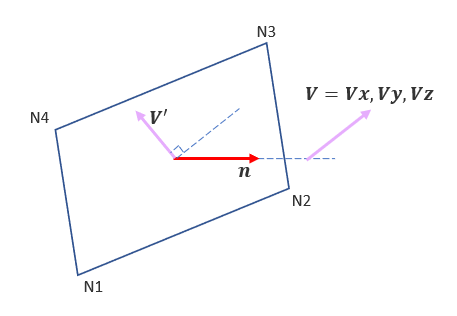

Figure 3. IP = 22 - If IP = 23, the vector

is defined with VX, VY and VZ. The reference vector

is the product of vector

and the shell element normal

direction

. Local coordinate system

skew_ID is ignored.

Figure 4. IP = 23

Then for each layer, the 1st material direction (m1) is vector turned degrees (turns positive direction around shell normal ).

Figure 5.The hierarchy order to define the reference vector is:- initial state card (/INISHE/ORTHO)

- shell property

In case of reference metrics, the orientation for directions of anisotropy must be defined with the reference geometry, not the initial one.

The 2nd material direction m2 derived from direction m1 rotated 90 degrees (orthotropic).

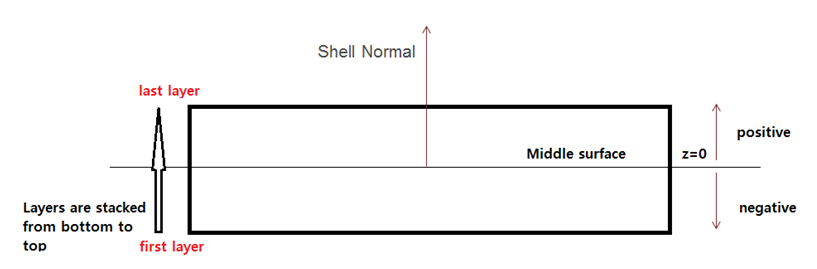

- Ipos – Layer position

- Ipos = 0: layer

positions are calculated automatically with "Thick". If

- A warning message is displayed.

- And individual layer thickness will be adjusted to new layer

thickness

with:

(1) Here Thick and are the shell thickness and layer thickness which are specified in input.

Figure 6.

- Ipos = 1: all layer

positions in the element thickness are user-defined (with

and

).

- “Thick” is not checked, as it does not need to be equal to the sum of layer thickness.

- Multiple layers are allowed to have the same space position.

For more details, refer to “Layer thickness and layer position calculation” in the Property and Elements FAQs.

- Ipos = 0: layer

positions are calculated automatically with "Thick".

- Mat_IDi- Material

for each layer

- Each layer as well as the corresponding part must use the same material law type. But may have different material properties, hence material IDs. Radioss checks for this condition and errors out if it is not met.

- Global material properties (membrane stiffness, bending stiffness, mass, and inertia) are calculated based on the material properties and layer (thicknesses …). They are used for stability, mass and interface stiffness.

- A material is still required at part definition level but, is only used for pre- and post- (visualization “by material”) and its physical characteristics are ignored.

- The previous formulation where stiffness and mass were calculated from the material associated to the part is still used if the version number of the input file is V13 or earlier.

- Element deletion

rules used with P_thickfail and

failure models:

- Only P_thickfail

defined in the property is considered to trigger the element failure.

- P_thickfail > 0 defines a fraction of failed thickness. This uses the amount of thickness assigned to each layer.

- P_thickfail < 0 defines a ratio of failed layers. This uses the number of layers.

- The P_thickfail defined in failure model(s) (/FAIL) are not used.

- For fully-integrated shells (Ishell=12), the rules described above for under-integrated shells applies to each Gauss point separately. P_thickfail criterion is checked for all integration point thickness for each in-plane Gauss point. The element is deleted only when all Gauss points reach P_thickfail criterion.

- P_thickfail rules are not used with failure models defined inside the material laws. It is used only for the failure model defined with /FAIL.

- Only P_thickfail

defined in the property is considered to trigger the element failure.