OS-E: 0850 V-Bracket using RADOPT

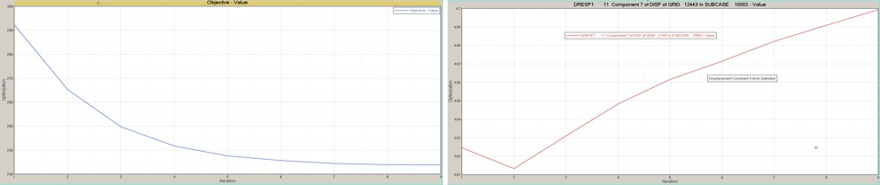

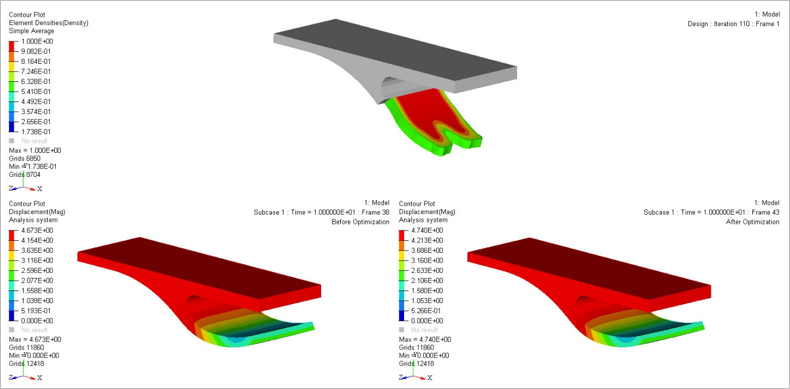

Demonstrates topology optimization of a V-bracket with RADOPT technique, using OptiStruct. RADOPT is Radioss optimization using OptiStruct. The equivalent static load method (ESLM) is used to perform the optimization run here.

Model Files

Before you begin, copy the file(s) used in this example to

your working directory.

Model Description

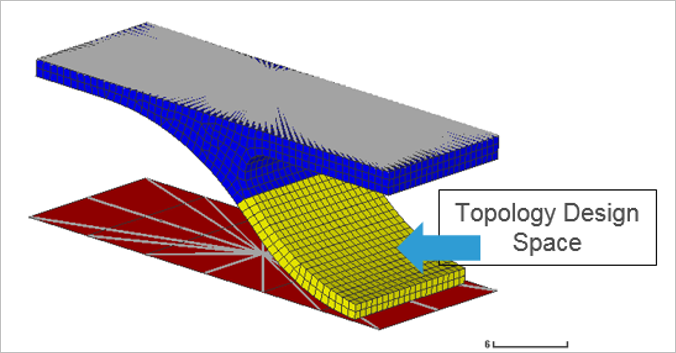

Conduct a topology optimization of the V-bracket which is undergoing a compression loading

(force applied in negative Y-direction), and the design space (yellow) in Figure 1.

- FE Model

- Elements Types

- HEXA

The linear material properties are:

- MAT1

- Young’s Modulus

- 2.1E5 MPa

- Poisson's Ratio

- 0.3

- Density

- 7.9E-9