OS-T: 2000 Design Concept for a Structural C-Clip

In this tutorial you will perform a topology optimization on a model to create a new topology for the structure, removing any unnecessary material. The resulting structure is lighter and satisfies all design constraints.

The topology optimization technique yields a new design and optimal material distribution. Topology optimization allows designers to start with a design that already has the advantage of optimal material distribution and is ready for design fine tuning with shape or size optimization.

- Objective

- Minimize volume fraction.

- Constraints

- Translation in the y-axis for node A < 0.07mm.

- Design variables

- The density of each element in the design space.

Launch HyperMesh and Set the OptiStruct User Profile

-

Launch HyperMesh.

The User Profile dialog opens.

-

Select OptiStruct and click

OK.

This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct.

Open the Model

- Click .

- Select the cclip.hm file you saved to your working directory.

-

Click Open.

The cclip.hm database is loaded into the current HyperMesh session, replacing any existing data.

Set Up the Model

Create the Material

-

In the Model Browser, right-click and select from the context menu.

A default material displays in the Entity Editor.

- For Name, enter steel.

- Set Card Image to MAT1.

-

Enter the material values next to the corresponding fields.

- For E (Young's Modulus), enter 2.1E5.

- For NU, (Poisson's Ratio), enter 0.3.

- For RHO (Mass Density),

A new material, steel, has been created. The material uses OptiStruct's linear isotropic material model, MAT1. - Click Close.

Create the Property

-

In the Model Browser, right-click and select from the context menu.

A default property displays in the Entity Editor.

- For Name, enter prop_shell.

- Set Card Image to PSHELL.

-

Enter the property values next to the corresponding fields.

An empty Value field indicates that it is turned off. To edit these properties, click on the blank Value fields next to them and enter the required values.

- For Material, click . In the Select Material dialog, select steel and click OK.

- For T (thickness of the plate), enter 1.0.

Assign a Material and Property to the comp_shell Component

-

In the Model Browser, Components folder, click comp_shell.

The component displays in the Entity Editor.

- For Property, click . In the Select Property dialog, select prop_shell and click OK.

Apply Loads and Boundary Conditions

Create Load Collectors

-

In the Model Browser, right-click and select from the context menu.

A default load collector displays in the Entity Editor.

- For Name, enter constraints.

- Click Color and select a color from the color palette.

- Set Card Image to None and click Close.

-

Create another load collector.

- For Name, enter forces.

- For Card Image, select None.

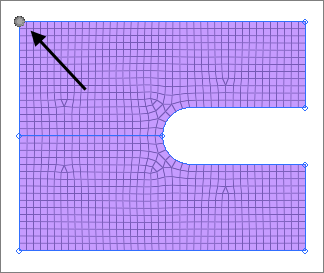

Create Constraints

- From the Model Browser, Load Collectors folder, right-click on Constraints and select Make Current from the context menu.

- From the Analysis page, click constraints.

-

Create the first constraint.

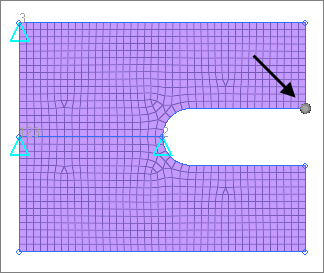

- Using the nodes selector, select the node indicated in Figure 1.

- Select the degree of freedom, dof3; unselect all others.

- Click create.

Figure 1.

-

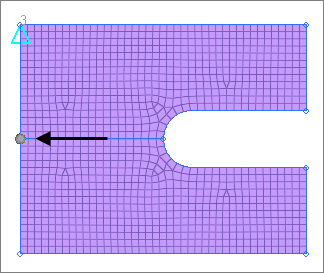

Create the second constraint.

- Using the nodes selector, select the node indicated in Figure 2.

- Select the degrees of freedom, dof1 - dof3; unselect all others.

- Click create.

Figure 2.

-

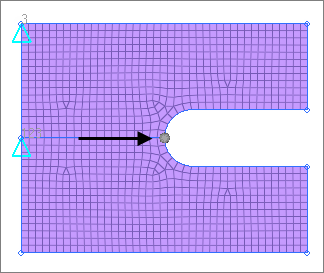

Create the third constraint.

- Using the nodes selector, select the node indicated in Figure 3.

- Select the degree of freedom, dof2; unselect all others.

- Click create.

Figure 3.

- Click return.

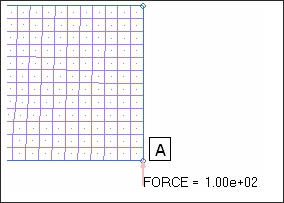

Create Forces

- From the Model Browser, Load Collectors folder, right-click on Forces and select Make Current from the context menu.

- From the Analysis page, click forces.

-

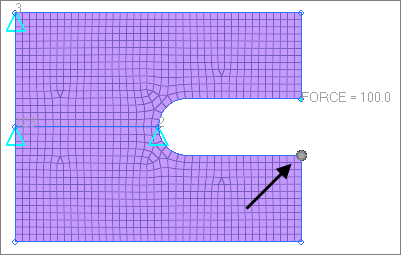

Create a force at the top of the opening of the c-clip.

- Using the nodes selector, select the node at the top of the opening of the clip.

- In the magnitude= field, enter 100.

- Set the vector selector to y-axis.

- Click create.

Figure 4.

-

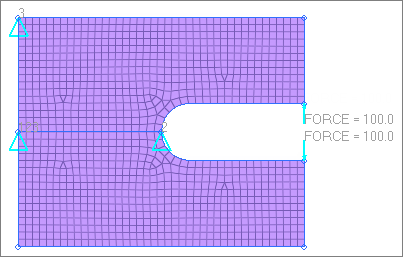

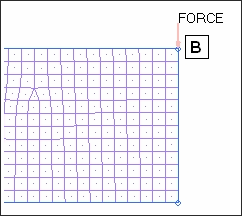

Create a force at the bottom of the opening of the c-clip.

- Using the nodes selector, select the node at the bottom of the opening of the clip.

- In the magnitude= field, enter -100.

- Set the vector selector to y-axis.

- Click create.

Figure 5.

-

To provide a separation between the arrows, enter 7 in

the uniform size= field.

Figure 6.

- Click return to go back to the Analysis page.

Create Load Steps

- In the Model Browser, right-click and select from the context menu.

- For Name, enter opposing forces.

- Set Analysis type to linear static.

-

Define SPC.

- For SPC, click to open Advanced Selection.

- In the dialog, select constraints and click OK.

- In Subcase Options, select .

- For LOAD, click to open Advanced Selection.

- In the dialog, select forces and click OK.

Submit the Job

A linear static analysis of this C-clip is performed prior to the definition of the optimization process. An analysis identifies the responses of the structure before optimization to ensure that constraints defined for the optimization are reasonable.

-

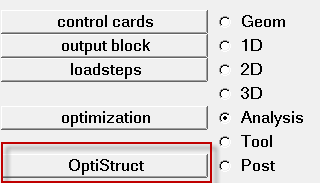

From the Analysis page, click the OptiStruct

panel.

Figure 7. Accessing the OptiStruct Panel

- Click save as.

-

In the Save As dialog, specify location to write the

OptiStruct model file and enter

cclip_complete for filename.

For OptiStruct input decks, .fem is the recommended extension.

-

Click Save.

The input file field displays the filename and location specified in the Save As dialog.

- Set the export options toggle to all.

- Set the run options toggle to analysis.

- Set the memory options toggle to memory default.

- Clear the options field.

- Click OptiStruct to launch the OptiStruct job.

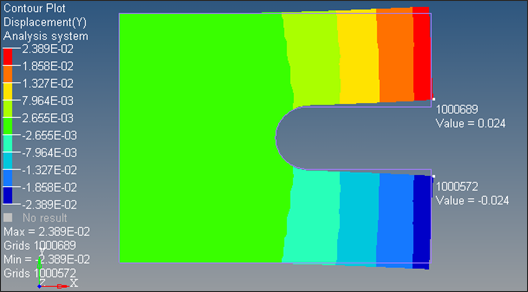

View the Results

-

From the OptiStruct panel, click

HyperView.

HyperView launches the cclip.mvw file which loads the model and the results files.

-

On the Results toolbar, click

to open the Contour panel.

to open the Contour panel.

- Under Result type, select Displacement(v) and Y.

-

Click Apply.

Figure 8. Contour of Y Displacements

- Verify if the values are equivalent to those in Figure 8.

-

From the Page Control toolbar, click the page delete

icon to delete the HyperView page.

Figure 9.

HyperView closes. - Click return to exit the panel.

Set Up the Optimization

The finite element model, consisting of shell elements, element properties, material properties, and loads and boundary conditions has been defined. Now a topology optimization will be performed with the goal of minimizing the amount of material to be used. Typically, removing the material in an existing volume with the same loads and boundary conditions makes the model less stiff and more prone to deformation. Therefore, you need to track the displacements (which represent the stiffness of the structure) and constrain the optimization process such that the least material necessary is used and overall stiffness is also achieved.

The forces in the structure are applied on the outer nodes of the opening of the clip, making those two nodes critical locations in the mesh where the maximum displacement is likely to occur. In this tutorial, you will apply a displacement constraint on the nodes so that they would not displace more than 0.07 in the y-axis.

Create Topology Design Variables

- From the Analysis page, click optimization.

- Click topology.

- Select the create subpanel.

- In the desvar= field, enter d_shell.

- Set type: to PSHELL.

- Using the props selector, select prop_shell.

-

Verify that the base thickness is 0.0.

A value of 0.0 implies that the thickness at a specific element can go to zero, and therefore becomes a void.

- Click create.

- Click return.

Create Optimization Responses

- From the Analysis page, click optimization.

- Click Responses.

-

Create the volume fraction response.

- In the responses= field, enter volfrac.

- Below response type, select volumefrac.

- Set regional selection to total and no regionid.

- Click create.

-

Create the displacement response.

Figure 10.

-

Create another displacement response, named lowerdis. Using the nodes selector,

select the node labeled B, on the lower opening of the c-clip.

Figure 11.

- Click return to go back to the Optimization panel.

Create Constraints on Displacement Responses

- Click the Dconstraints panel.

-

Create the upper bound constraint.

- In the constraint= field, enter c_upper.

- Check the box next to upper bound, then enter 0.07.

- Click response= and select upperdis.

- Using the loadsteps selector, select opposing forces.

- Click create.

-

Create the lower bound constraint.

- In the constraint= field, enter c_lower.

- Check the box next to lower bound, then enter -0.07.

- Click response= and select lowerdis.

- Using the loadsteps selector, select opposing forces.

- Click create.

- Click return to go back to the Optimization panel.

Define the Objective Function

- Click the objective panel.

- Verify that min is selected.

- Click response= and select volfrac.

- Click create.

- Click return twice to exit the Optimization panel.

Create the SCREEN Card

- From the Analysis page, click control cards.

- In the Card Image dialog, click SCREEN.

- Click return.

- Click return.

Run the Optimization

- From the Analysis page, click OptiStruct.

- Click save as.

-

In the Save As dialog, specify location to write the

OptiStruct model file and enter

cclip_complete for filename.

For OptiStruct input decks, .fem is the recommended extension.

-

Click Save.

The input file field displays the filename and location specified in the Save As dialog.

- Set the export options toggle to all.

- Set the run options toggle to optimization.

- Set the memory options toggle to memory default.

-

Click OptiStruct to run the optimization.

The following message appears in the window at the completion of the job:

OPTIMIZATION HAS CONVERGED. FEASIBLE DESIGN (ALL CONSTRAINTS SATISFIED).

OptiStruct also reports error messages if any exist. The file cclip_complete.out can be opened in a text editor to find details regarding any errors. This file is written to the same directory as the .fem file. - Click Close.

- cclip_complete.hgdata

- HyperGraph file containing data for the objective function, percent constraint violations, and constraint for each iteration.

- cclip_complete.HM.comp.tcl

- HyperMesh command file used to organize elements into components based on their density result values. This file is only used with OptiStruct topology optimization runs.

- cclip_complete.oss

- OSSmooth file with a default density threshold of 0.3. You may edit the parameters in the file to obtain the desired results.

- cclip_complete.out

- OptiStruct output file containing specific information on the file setup, the setup of the optimization problem, estimates for the amount of RAM and disk space required for the run, information for all optimization iterations, and compute time information. Review this file for warnings and errors that are flagged from processing the cclip_complete.fem file.

- cclip_complete.res

- HyperMesh binary results file.

- cclip_complete.sh

- Shape file for the final iteration. It contains the material density, void size parameters and void orientation angle for each element in the analysis. This file may be used to restart a run.

- cclip_complete.stat

- Contains information about the CPU time used for the complete run and also the break-up of the CPU time for reading the input deck, assembly, analysis, convergence, and so on.

- cclip_complete_hist.mvw

- Contains the iteration history of the objective, constraints, and the design variables. It can be used to plot curves in HyperGraph, HyperView, and MotionView.

- cclip_complete.h3d

- HyperView binary results file.

View the Results

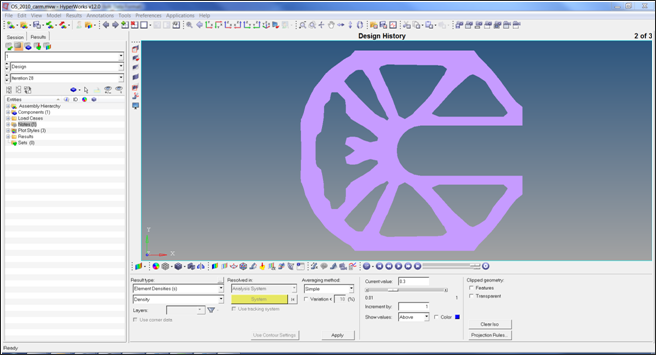

Element density results are output to the cclip_complete_des.h3d file from OptiStruct for all iterations. In addition, Displacement and Stress results are output for each subcase for the first and last iterations by default into cclip_complete_s#.h3d files, where # specifies the sub case ID.

View an Iso Value Plot of Element Densities

-

From the OptiStruct panel, click HyperView.

HyperView launches inside of HyperMesh Desktop, and opens the session file cclip_complete.mvw which contains two pages with the results from two files.

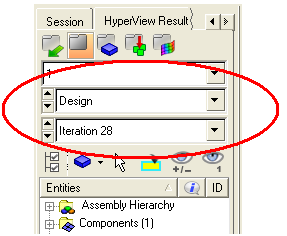

- Page 2

- Displays the file cclip_complete_des.h3d, which contains the Optimization history results (element density).

- Page 3

- Displays the cclip_complete_s1.h3d, which contains the Subcase 1 results; initial and final (displacement stress).

- Verify that you are on page 2.

-

In the Results Browser, under the load case section, select

Design and the last iteration listed to review the

optimized iteration result.

Figure 12.

- On the Standard Views toolbar, click XY Top Plane View to set the correct view.

- From the menu bar, click .

- In the panel area, set Result type to Element Densities.

- Click Apply.

- In the Current value field, enter 0.3.

-

Under Current value, move the slider to change the density threshold.

Use this tool to get a better look at the material layout and the load paths from OptiStruct.The iso value in the modeling window update interactively when you scroll to a new value.

Figure 13. Iso Value Plot of Element Densities

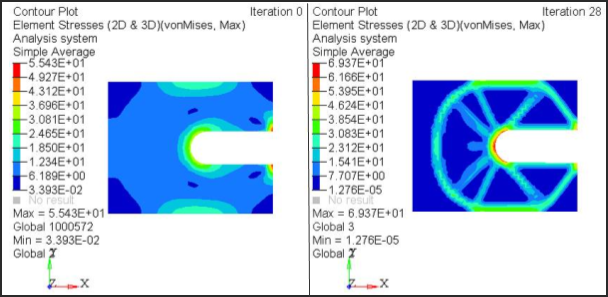

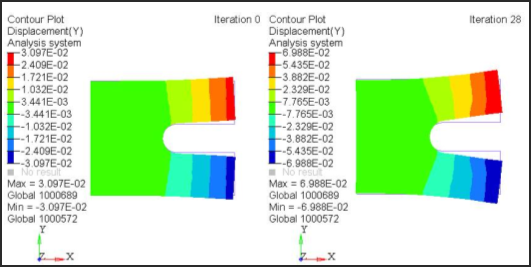

Compare Original Static Contour to Optimized Material Layout

-

In HyperView, click

to go to

page 3.

The cclip_complete_s1.h3d file displays, which contains the static subcase results for the first and last iteration steps.

to go to

page 3.

The cclip_complete_s1.h3d file displays, which contains the static subcase results for the first and last iteration steps. -

On the Page Controls toolbar, from the Page Window Layout drop-down, click

to divide the page into two vertical windows.

to divide the page into two vertical windows.

- On the Standard Views toolbar, click XY Top Plane View to set the correct view.

- From the menu bar, click .

- Under Result type, select Displacement and Y.

- Click Apply.

-

Click

to open the Deformed panel.

to open the Deformed panel.

- Under Deformed shape, enter 100 in the Value field.

- Under Undeformed shape, set Show to Edges.

- Click Apply.

-

Copy the contents of the first window to the second window.

- From the menu bar, click .

- Click the empty window.

- From the menu bar, click .

-

Switch the animation mode to Linear

.

.

-

With the second window selected, select Iteration

28.

Figure 14.

-

Create a third page.

- From the menu bar, click .

- From the menu bar, click .

-

Activate the first window and click

to open the Contour panel.

to open the Contour panel.

- Under Result type, select Element Stresses (2D & 3D) (t).

- Set Averaging method to Simple.

- Click Apply.

-

In the first window, right-click and select from the context menu.

Figure 15.