可研究结构中点焊的疲劳性能。

目前,仅支持基于应力-寿命 (SN) 的点焊疲劳分析。点焊位置由三个属性定义:薄片 1、薄片 2 和焊点熔核。

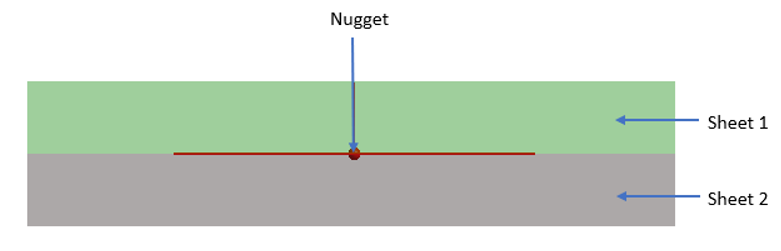

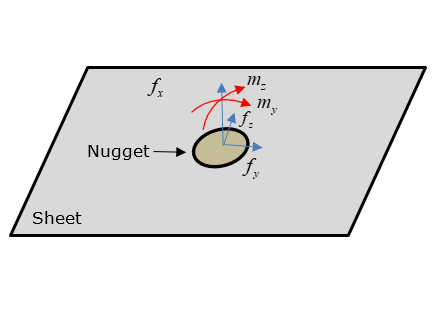

Figure 1. 点焊疲劳

执行

点焊的疲劳分析包括在三个不同的位置检查焊缝,薄片和焊点熔核,这是基于 Rupp 等人发表的一篇论文。确定焊点熔核位置处的截面力和力矩,然后计算薄片和焊点熔核的相应应力。然后再使用这些应力并结合雨流计数和 SN 方法来计算疲劳损伤。

以下各部分说明了如何计算这三个位置的应力和随后的损伤。

薄片位置(1 或 2)

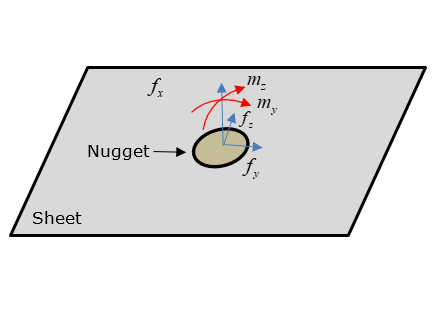

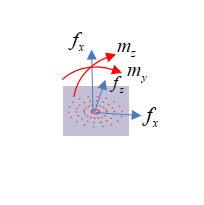

Figure 2. 薄片位置上的力和目标力矩

通过考虑焊点熔核处的力和力矩来计算薄片的径向应力。径向应力

作为载荷-时间历史中每个点的

的函数计算如下:

其中,

-

- 焊缝单元的直径

-

- 损伤计算时考虑的薄片厚度

-

,

,

- 比例因子

-

,

,

- 直径指数

-

,

,

- 厚度指数

等效于 Rupp 方法:

等效径向应力以

为间隔进行计算(默认值 = 18 度)。可以通过改变点焊求解设置中的角度数量字段来修改

的值。然后,采用雨流循环计数法计算各角度下的疲劳寿命和损伤 (

)。然后选择最严重的损伤值进行输出。对另一个薄片也采用类似的方法。

焊点熔核位置

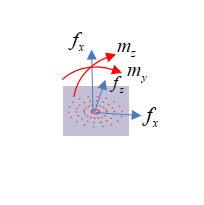

Figure 3. 焊点熔核横截面的力和力矩

绝对最大主应力是使用梁单元的剪切应力和弯曲应力作为载荷-时间历史中每个点的函数

来计算的,如下所示:

其中,

-

- 焊缝单元的直径

-

- 损伤计算时考虑的薄片厚度

从

和

计算每个

的等效最大绝对主应力。这些应力被用于后续的疲劳分析。采用雨流循环计数法计算各角度下的疲劳寿命和损伤 (

)。然后选择最严重的损伤值进行输出。