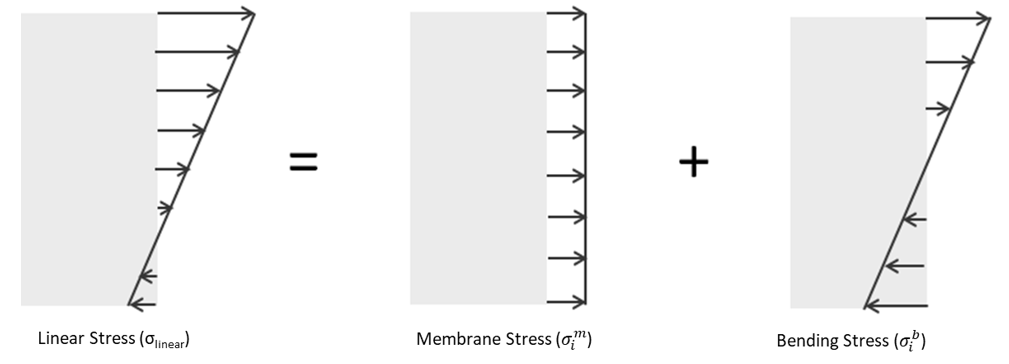

在 SimSolid 中执行的缝焊疲劳是基于应力的线性化和 Volvo 方法,然后预测疲劳损伤和寿命。线性化应力能够将贯穿厚度的弹性应力场分解为等效的膜应力和弯曲应力。

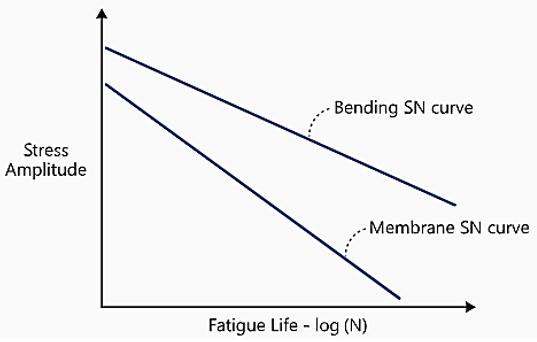

这种方法确定了弯曲对总应力的贡献,并由此确定焊缝本质上是刚性的还是柔性的。该方法通常需要两条 S-N 曲线。一种是以弯曲应力为主的弯曲 S-N 曲线,另一种是以膜应力为主的膜 S-N 曲线。根据弯曲程度在弯曲和膜 SN 曲线之间进行内插。

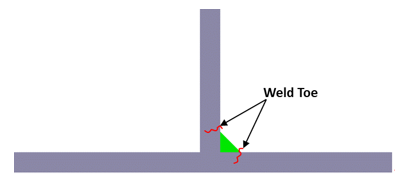

在焊趾处标记预计或可能的失效(疲劳裂纹)位置。这些是将评估疲劳损伤的位置。

Figure 1 . 角焊缝横截面显示可能的失效位置

焊缝应力计算

SimSolid 中的缝焊疲劳损伤计算使用应力线性化方法(链接至

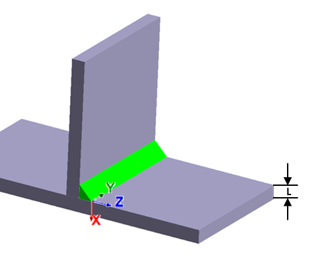

SimSolid 线性化应力文件)和与该应力相关的弯曲率,在相关位置使用结构应力。线性化应力在沿应力线性化段的局部坐标系中获得。局部坐标系以段的起始点和结束点为基础,如

Figure 2 所示。系统的 X 轴沿着从入口点到出口点的段。其他两个轴的计算方法如下:

Figure 2 . 根据上述提取的应力值,采用数值积分的方法计算出入口点和出口点的平均膜应力张量加上末端弯曲应力张量。

其中,

σ

i

m

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadMgaaeaacaWGTbaaaaaa@39C3@

i

t

h

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAamaaCa

aaleqabaGaamiDaiaadIgaaaaaaa@38F4@

个分量。

σ

i

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaadMgaaeqaaaaa@38D0@

i

t

h

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAamaaCa

aaleqabaGaamiDaiaadIgaaaaaaa@38F4@

σ

i

S

b

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadMgacaWGtbaabaGaamOyaaaaaaa@3A90@

i

t

h

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAamaaCa

aaleqabaGaamiDaiaadIgaaaaaaa@38F4@

σ

i

E

b

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadMgacaWGfbaabaGaamOyaaaaaaa@3A82@

i

t

h

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAamaaCa

aaleqabaGaamiDaiaadIgaaaaaaa@38F4@

个分量。

L

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamitaaaa@36C4@

i

t

h

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAamaaCa

aaleqabaGaamiDaiaadIgaaaaaaa@38F4@

x

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiEaaaa@36F0@

用于缝焊损伤参数的应力量是膜应力和弯曲应力之和。

Figure 3 . 因此,顶面和底面的应力由以下等式得出:

Note: 因此,缝焊分析引擎中使用的计算方法同样适用于从实体或薄壳体模型计算的应力。这将生成与薄壳体模型相同形式的顶面和底面应力。

Figure 4 . 弯曲比 (r)

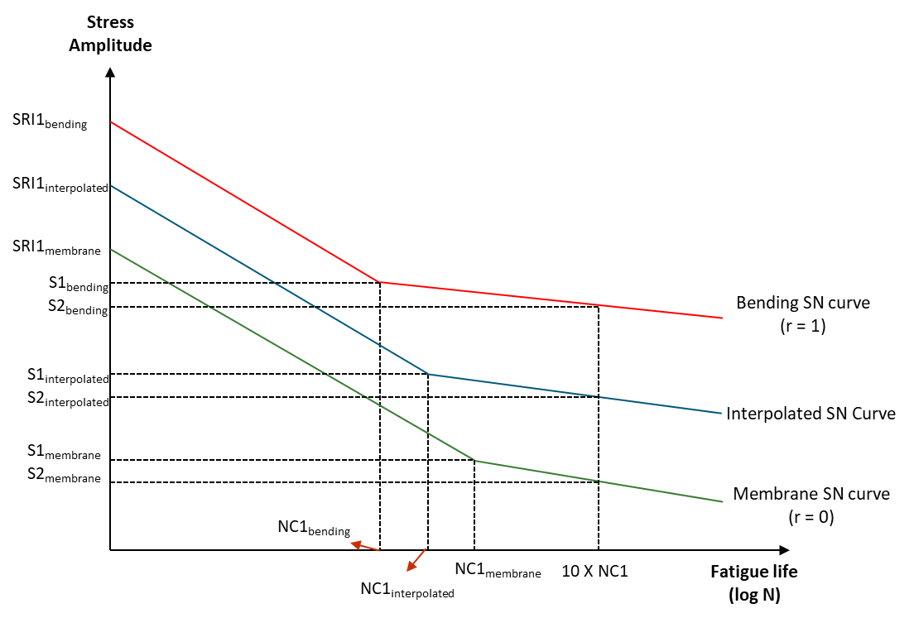

实验表明,根据 M. Fermér、M Andréasson 和 B Frodin 提出的方法,需要两种类型的 SN 曲线来进行缝焊疲劳分析。根据实验室测试,绘制了两条 SN 曲线(

Figure 5 )。上面的曲线是在最大应力由弯曲力矩控制的试验中获得的,下面的曲线是在最大应力由膜力控制的试验中获得的。

Figure 5 . 上下两条曲线分别称为弯曲 S-N 曲线和膜 S-N 曲线。建议当膜应力在单元中占主导地位时使用膜 S-N 曲线,当弯曲应力占主导地位时使用弯曲 S-N 曲线。根据弯曲优势程度,可以在两条曲线之间进行内插。

其中,

σ

i

b

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadMgaaeaacaWGIbaaaaaa@39B8@

6

T

2

∫

−

T

/

2

T

/

2

σ

i

x

d

x

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaSaaaeaaca

aI2aaabaGaamivamaaCaaaleqabaGaaGOmaaaaaaGcdaWdbaqaamaa

DaaaleaacqGHsislcaWGubGaai4laiaaikdaaeaacaWGubGaai4lai

aaikdaaaaabeqab0Gaey4kIipakiabeo8aZnaaBaaaleaacaWGPbaa

beaakiaadIhacaWGKbGaamiEaaaa@45FD@

σ

i

m

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadMgaaeaacaWGTbaaaaaa@39C3@

1

T

∫

−

T

/

2

T

/

2

σ

i

d

x

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaSaaaeaaca

aIXaaabaGaamivaaaadaWdbaqaamaaDaaaleaacqGHsislcaWGubGa

ai4laiaaikdaaeaacaWGubGaai4laiaaikdaaaaabeqab0Gaey4kIi

pakiabeo8aZnaaBaaaleaacaWGPbaabeaakiaadsgacaWG4baaaa@4408@

平均弯曲比,

(

r

b

A

V

G

)

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaaiikaiaadk

hadaqhaaWcbaGaamOyaaqaaiaadgeacaWGwbGaam4raaaakiaacMca aaa@3BCE@

,定义为:

其中,

σ

T

O

P

2

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aa0

baaSqaaiaadsfacaWGpbGaamiuaaqaaiaaikdaaaaaaa@3B21@

r

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCaaaa@36EA@

它是加载时间关系中所有点的弯曲率的加权平均值。

内插因子 (IF) 现在定义为:

r

b

T

H

R

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaDa

aaleaacaWGIbaabaGaamivaiaadIeacaWGsbaaaaaa@3A7B@

r

b

A V G

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaDa

aaleaacaWGIbaabaGaamyqaiaadAfacaWGhbaaaaaa@3A6B@

r

b

T H R

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaDa

aaleaacaWGIbaabaGaamivaiaadIeacaWGsbaaaaaa@3A7B@

膜曲线与弯曲 S-N 曲线之间的内插

Figure 6 . 线性内插法,如

Figure 6 所示,使用内插系数 (IF) 的值。对于内插曲线,疲劳强度系数值 (SRI1) 的计算如下:

interpolated = SRI1membrane + (SRI1bending – SRI1membrane ) ∙ IF

这定义了 1 个周期的应力水平。

interpolated = 10(log 10 Nc1 membrane + (log 10 Nc1 bending – log 10 (Nc1 membrane ) ∙IF))

interpolated = S1membrane + (S1bending – S1membrane ) ∙ IF

这定义了 Nc1interpolated 个周期的应力水平。这两个点定义了曲线的第一部分,最多 Nc1interpolated 个周期。最后一部分通过寻找第三个点来定义,如下所示。对于刚性和柔性曲线,寿命值被定义为 Nc1 值的 10 倍。由此可以计算出 S2bending 和 S2membrane 。由此,我们可以进行内插,得到定义曲线高周部分的 S2interpolated 。

interpolated = S2membrane + (S2bending – S2membrane )IF

厚度

或者,可以基于零件的厚度 t 施加厚度(尺寸效应校正)。运行方式如下:

如果

t ≤

T

r e f

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiDaiabgs

MiJkaadsfadaWgaaWcbaGaamOCaiaadwgacaWGMbaabeaaaaa@3C72@

疲劳强度由

T

r

e

f

t

n

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaada

WcaaqaaiaadsfadaWgaaWcbaGaamOCaiaadwgacaWGMbaabeaaaOqa

aiaadshaaaaacaGLOaGaayzkaaWaaWbaaSqabeaacaWGUbaaaaaa@3D80@

n 是厚度指数,如果

t

>

T

r

e

f

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiDaiabg6

da+iaadsfadaWgaaWcbaGaamOCaiaadwgacaWGMbaabeaaaaa@3BC5@

平均应力修正

支持对缝焊疲劳进行 FKM 平均应力修正。应力敏感性可通过平均应力修正字段在疲劳求解设置对话框中定义。可以通过缝焊疲劳求解设置对话框启用缝焊疲劳的平均应力修正。

据 FKM 准则,根据应力比 (R=Smin /Smax ) 值将 Haigh 图表分为四个区域。然后使用修正后的值选择损害和寿命计算阶段的 SN 曲线。

下面的 FKM 方程说明了修正应力振幅的计算过程 (

S

e

A

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaaaaa@38A8@

)。损害计算中使用的实际应力值是修正的应力振幅(即

2

⋅

S

e

A

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaaGOmaiabgw

SixlaadofadaqhaaWcbaGaamyzaaqaaiaadgeaaaaaaa@3BAE@

)。这些公式适用于所输入的 SN 曲线。

区域 1 (R>1.0 ):

S

e

A

=

S

a

(

1

−

M

)

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaakiabg2da9iaadofadaWgaaWcbaGa

amyyaaqabaGccaGGOaGaaGymaiabgkHiTiaad2eacaGGPaaaaa@3F7F@

区域 2 (

−

∞

≤

R

≤

0.0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeyOeI0Iaey

OhIuQaeyizImQaamOuaiabgsMiJkaaicdacaGGUaGaaGimaaaa@3EB8@

S

e

A

=

S

a

+

M

*

S

m

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaakiabg2da9iaadofadaWgaaWcbaGa

amyyaaqabaGccqGHRaWkcaWGnbGaaiOkaiaadofadaWgaaWcbaGaam

yBaaqabaaaaa@4004@

区域 3 (0.0<R<0.5 ):

S

e

A

=

(

1

+

M

)

S

a

+

(

M

/

3

)

*

S

m

1

+

M

/

3

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaakiabg2da9iaacIcacaaIXaGaey4k

aSIaamytaiaacMcadaWcaaqaaiaadofadaWgaaWcbaGaamyyaaqaba

GccqGHRaWkcaGGOaGaamytaiaac+cacaaIZaGaaiykaiaacQcacaWG

tbWaaSbaaSqaaiaad2gaaeqaaaGcbaGaaGymaiabgUcaRiaad2eaca

GGVaGaaG4maaaaaaa@4A8E@

区域 4 (

R

≥

0.5

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOuaiabgw

MiZkaaicdacaGGUaGaaGynaaaa@3ABB@

S

e

A

=

3

S

a

(

1

+

M

)

2

3

+

M

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaakiabg2da9maalaaabaGaaG4maiaa

dofadaWgaaWcbaGaamyyaaqabaGccaGGOaGaaGymaiabgUcaRiaad2

eacaGGPaWaaWbaaSqabeaacaaIYaaaaaGcbaGaaG4maiabgUcaRiaa

d2eaaaaaaa@43A5@

其中,

S

e

A

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaDa

aaleaacaWGLbaabaGaamyqaaaaaaa@38A8@

S

m

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaBa

aaleaacaWGTbaabeaaaaa@37E9@

M 是平均应力敏感性。 Figure 7 .