Tutorial: Strain Energy Density Analysis

Tutorial Level: Beginner Run a normal modes analysis and examine the strain energy density results.

In this lesson, you will:

- Run a normal modes analysis on a simple bracket supporting a mass

- Examine the strain energy density results

- Change the design of the bracket (without adding any mass) based on these results

- Compare the designs

The purpose of the tutorial is to demonstrate the following principles:

- When a structure deforms, different regions strain by different amounts. The sum of the energy in the structure due to the deformation is called the strain energy.

- Eigenvalues are normalized when a modal analysis is performed. The strain energy density results are used to determine which areas of the structure are under the greatest strain and contribute most to the stiffness.

- Targeting areas of high strain energy density for design changes is a common method to increase the natural frequencies in a modal analysis.

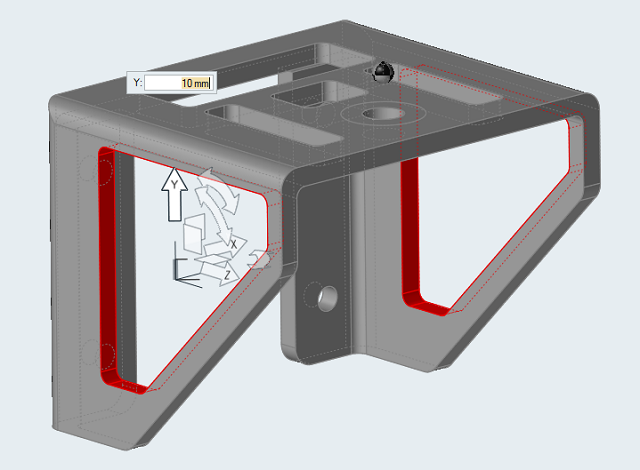

Examine the Model and Run a Modal Analysis

- Press F7 to open the Demo Browser.

-

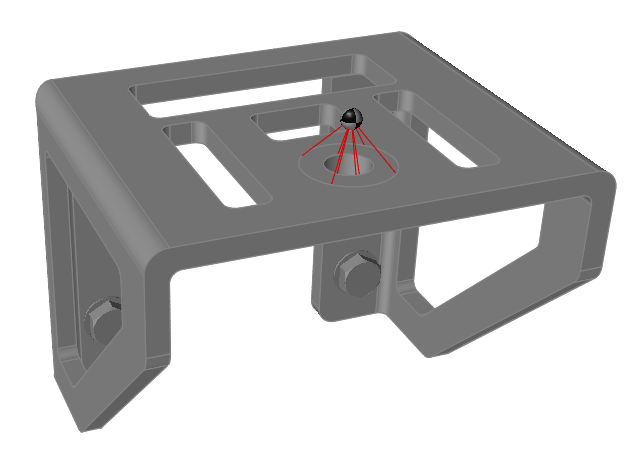

Double-click the 0.0_SED_tutorial.stmod file to load it in

the modeling window. Note that the model has a concentrated mass and four

grounded bolts in a load case.

- Make sure the display units in the Unit System Selector are set to MMKS (mm kg N s).

-

Create a modal load case:

-

On the Structure ribbon, click the Modal

button.

-

Click the Supports collector and select the four

grounded bolts.

- Change the number of Modes to 3.

- Click OK.

-

On the Structure ribbon, click the Modal

button.

-

On the Structure ribbon, click the

Run Analysis

button in the

Analyze tool group.

button in the

Analyze tool group.

-

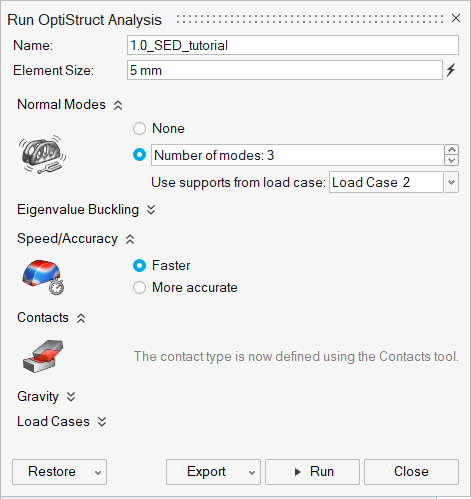

Run a Normal Modes analysis using the following settings:

Review the Strain Energy Density Results

-

When the analysis is complete, select it in the Run Status window and click

View Now to view the results.

Tip: You can also double-click the Results icon in the Model Browser to view results for a load case.

-

Click the

button on the animation

toolbar to visualize the displacement. Click the

button on the animation

toolbar to visualize the displacement. Click the  button to pause the

animation. Note that although the mode shape is clear, it is difficult to know

which parts of the structure are most critical.

button to pause the

animation. Note that although the mode shape is clear, it is difficult to know

which parts of the structure are most critical.

-

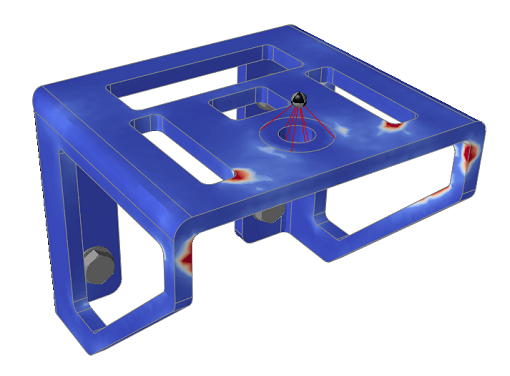

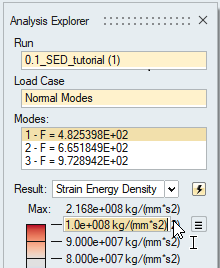

Adjust the Analysis Explorer using the following settings:

- Select Strain Energy Density under Result.

- Double-click the legend maximum and change it to 50 J/mm3.

This highlights the areas of the structure with the highest relative strain. Adding material to these high strain regions is normally a good way to increase the natural frequency.

Add Material to the High Strain Regions

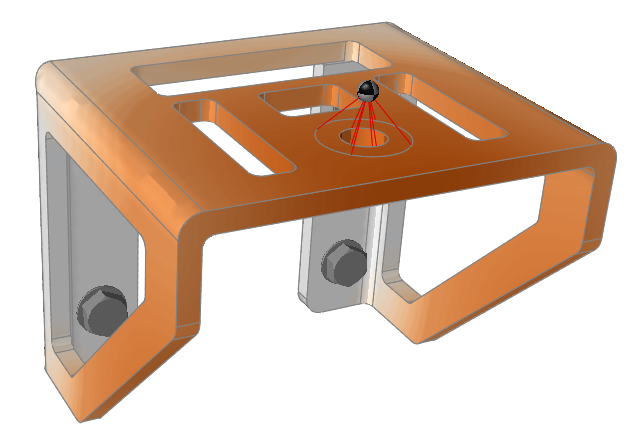

-

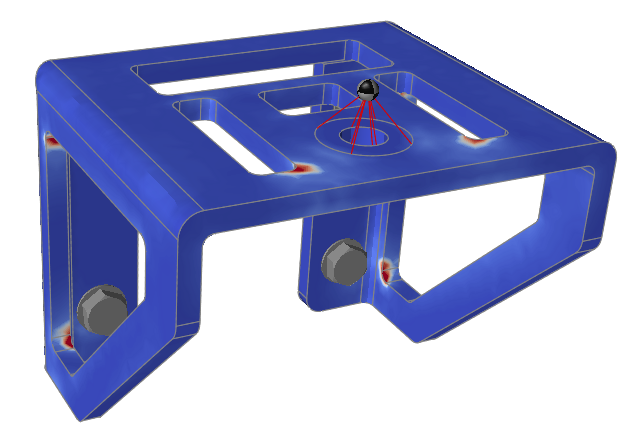

On the Geometry ribbon, select the Move Faces

tool.

Note: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

Click each face of the large side cutouts with the Move

Faces tool to select them.

-

Click the Z Translation arrow and type 20

mm in the box to move the cutouts in the Z direction.

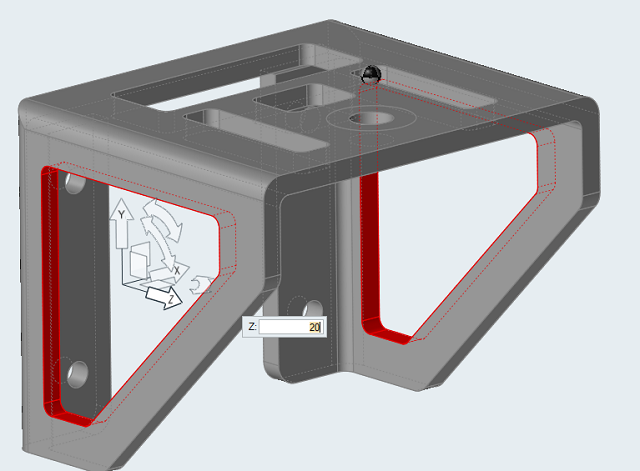

-

Click the Y Translation arrow and type 10

mm to move the cutouts in the Y direction. This adds material to

the area of high strain energy density without changing the mass of the

design.

-

On the Structure ribbon, click the

Run Analysis

button in the

Analyze tool group to run the analysis again.

button in the

Analyze tool group to run the analysis again.

In the Analysis Explorer, note that the first frequency has increased from 372 Hz to 388 Hz.

- In the Analysis Explorer, click Compare Results.

-

Right-click the top of the table and choose Normal Modes

to display the normal mode results.

Compare Results is a powerful tool to track analysis results and design performance

against model changes.

In summary, targeting areas of high strain energy density is a powerful approach for increasing the stiffness of structures. In this tutorial, the first mode was increased significantly with no material added.