Tutorial: Inertia Relief Analysis

Tutorial Level: Beginner Define a force using components and run an analysis with inertia relief.

Overview

Inertia relief is a numerical method used for analyzing unconstrained structures. A typical example is an aircraft in steady flight where the lift, drag, and thrust loads are balanced by gravity acting on the mass of the total aircraft. This acceleration due to gravity is equal and opposite to the acceleration that would result for the unconstrained structure.

At a component level, with inertia relief it is possible to analyze a part in isolation if the loads at the interface points are known or can be measured/calculated and the part can be considered to be in static equilibrium.

- load setup

- running inertia relief

| Location | Shock | Pivot | Axle | |

|---|---|---|---|---|

| Force | Fx N | -2352 | 980 | 1372 |

| Fy N | 3211 | -3700 | 489 | |

| Fz N | -635 | 645 | 0 | |

| Moment | Mx N*mm | 0 | -104867 | -278 |

| My N*mm | 0 | -188238 | 779 | |

| Mz N*mm | 0 | 0 | -7998 |

Apply a Component Force to the Shock Mount

- Press F7 to open the Demo Browser.

-

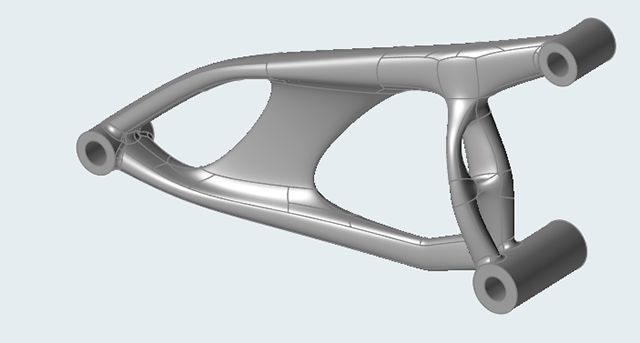

Double-click the 0.0_swingarm_IR_FEA.x_b file to load it

in the modeling window.

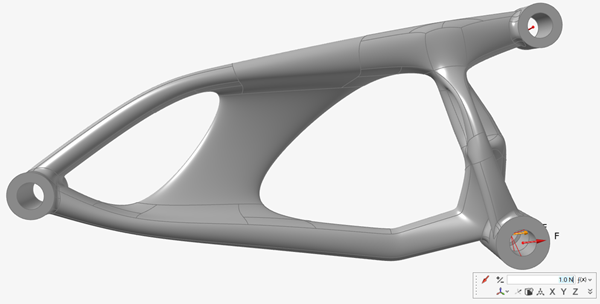

This is a solid model of a single-part motorcycle swing arm.

- Make sure the display units in the Unit System Selector are set to MMKS (mm kg N s).

-

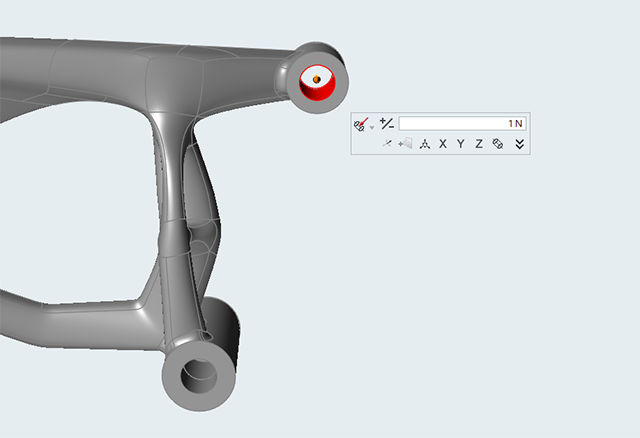

On the Structure ribbon, click the Force

button in the Loads tool group.

button in the Loads tool group.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

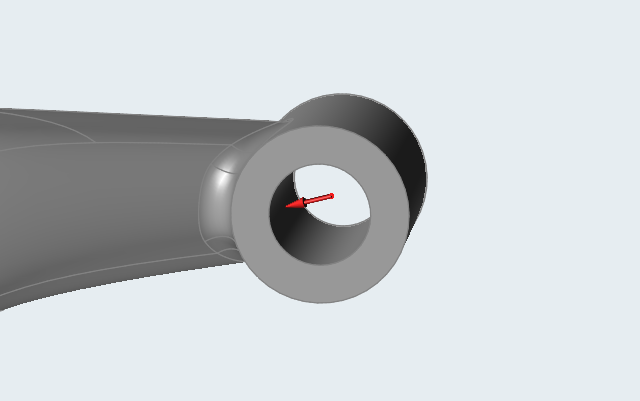

Click to apply the force to the hole center of the shock mount.

-

Click Vector Mode

on the

microdialog to switch to Component Mode, and then click the

on the

microdialog to switch to Component Mode, and then click the  chevron

to expand it.

chevron

to expand it.

-

Enter the following values:

- Fx: -2352 N

- Fy: 3211 N

- Fz: -635 N

- Right-click and mouse through the check mark to exit, or double-right-click.

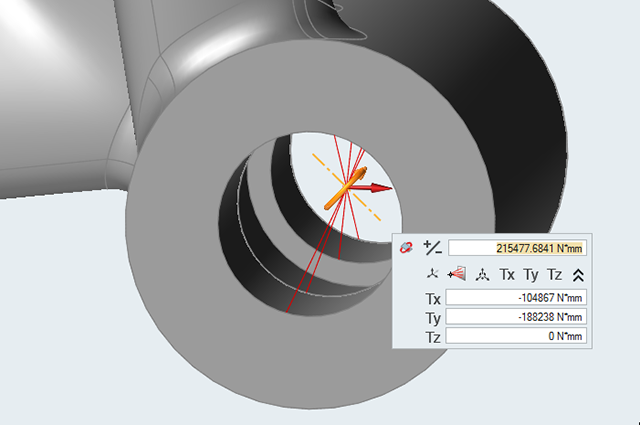

Apply a Component Force and Moment to the Swing Arm Pivot

- Zoom in on the swing arm pivot.

-

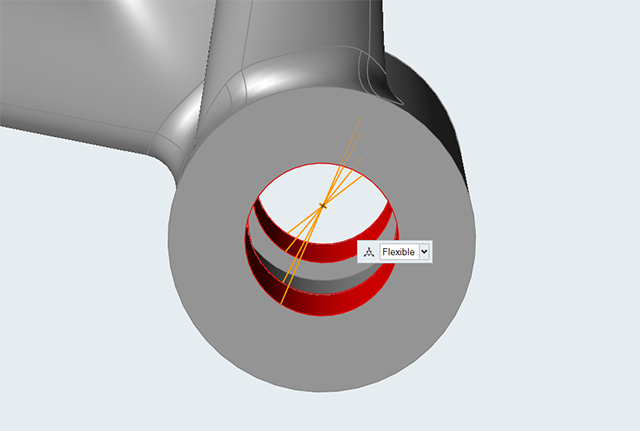

On the Structure ribbon, select the Connectors

tool.

Tip: To find and open a tool, press Ctrl+F. For more information, see Find and Search for Tools. -

Select the two faces as shown below to create a connector at the center of the

hole:

-

On the Structure ribbon, click the Force

button in the Loads tool group.

button in the Loads tool group.

- Click the connector at the center of the hole.

-

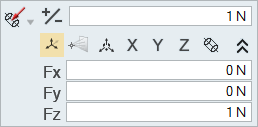

Click

Vector Mode

on the

microdialog to switch to Component Mode, and click the

on the

microdialog to switch to Component Mode, and click the

chevron

to expand it.

chevron

to expand it.

-

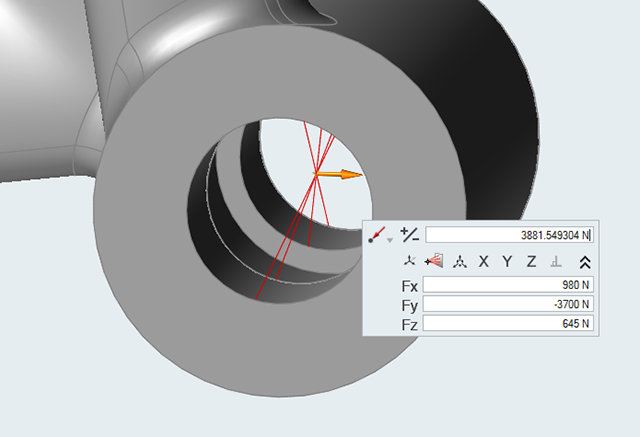

Enter the following values:

- Fx: 980 N

- Fy: -3700 N

- Fz: 645 N

-

On the Structure ribbon, click the Torque

button in the Loads tool group.

button in the Loads tool group.

- Click the connector at the center of the hole.

-

Click Vector Mode

on the

microdialog to switch to Component Mode, and click the

on the

microdialog to switch to Component Mode, and click the

chevron to expand it.

chevron to expand it.

-

Enter the following values:

- Tx: -104867 N*mm

- Ty: -188238 N*mm

- Tz: 0 N*mm

- Right-click and mouse through the check mark to exit, or double-right-click.

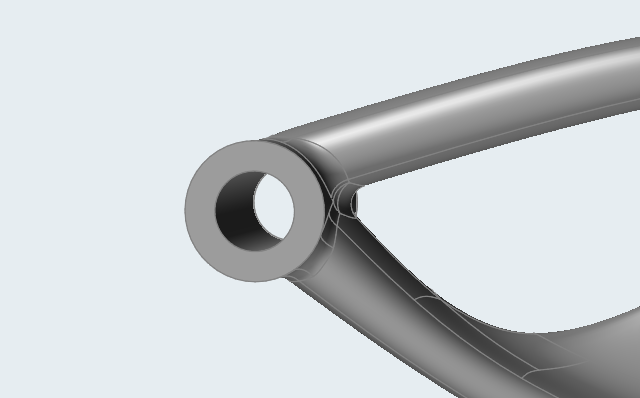

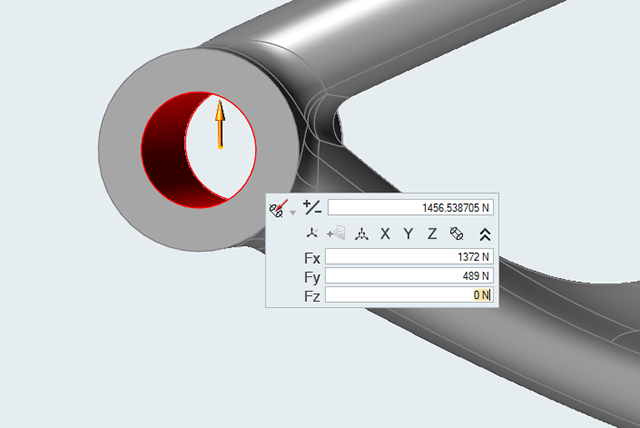

Apply a Component Force and Moment to the Center of the Axle

-

Zoom in on the center of the axle.

-

On the

Structure ribbon, click the Force

button in the Loads tool group.

button in the Loads tool group.

-

Select the face as shown below to apply a force to the hole center of the

axle.

-

Click

Vector Mode

on the

microdialog to switch to Component Mode, and click the

on the

microdialog to switch to Component Mode, and click the

chevron

to expand it.

chevron

to expand it.

-

Enter the following values:

- Fx: 1372 N

- Fy: 489 N

- Fz: 0 N

-

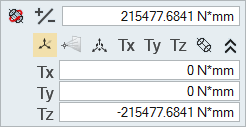

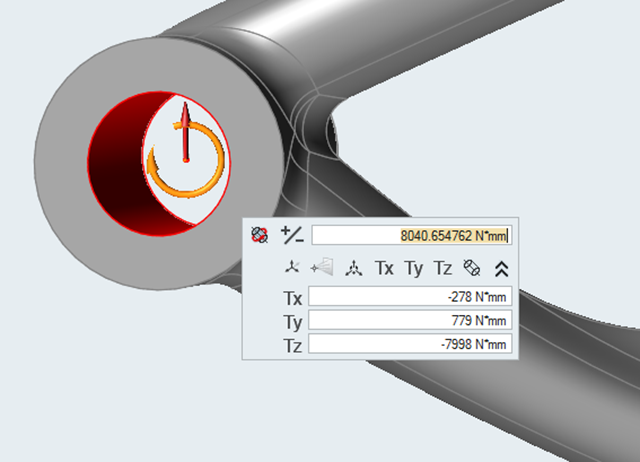

On the Structure ribbon, click the Torque

button in

the Loads tool group.

button in

the Loads tool group.

-

Select the face shown below to apply a torque to the hole center of the

axle.

-

Click Vector Mode

on the

microdialog to switch to Component Mode, and click the

on the

microdialog to switch to Component Mode, and click the

chevron

to expand it.

chevron

to expand it.

-

Enter the following values:

- Tx: -278 N*mm

- Ty: 779 N*mm

- Tz: -7998 N*mm

- Right-click and mouse through the check mark to exit, or double-right-click.

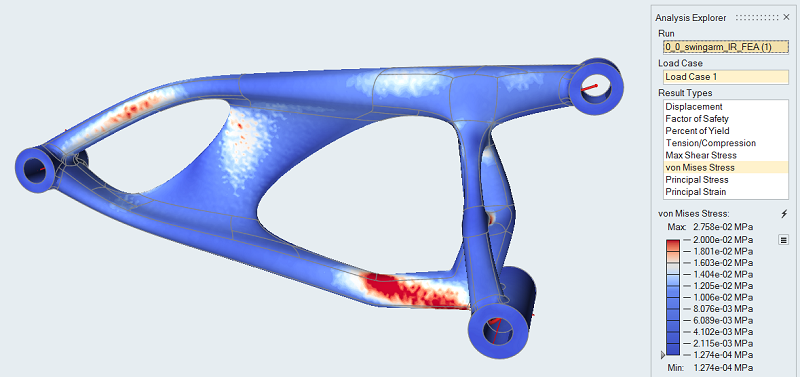

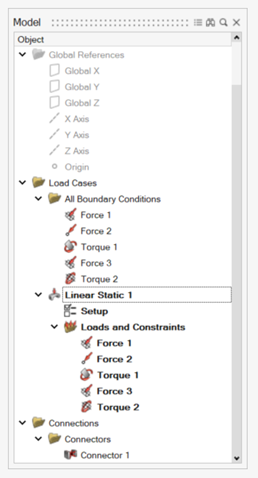

Run an Analysis with Inertia Relief

-

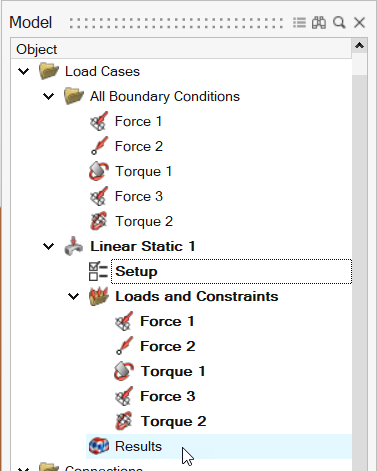

Press F2 to open the Model

Browser.

Note that a default linear static load case has been created containing all the created loads.

-

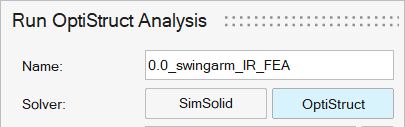

On the Structure ribbon, click the Run Analysis

button in the

Analyze tool group and ensure

OptiStruct is selected as the solver.

button in the

Analyze tool group and ensure

OptiStruct is selected as the solver.

-

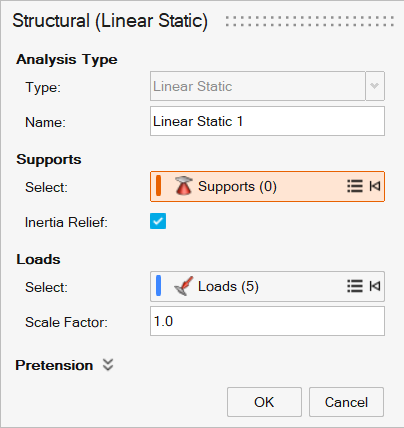

In the Model Browser, double-click Setup under the

Linear Static 1 heading.

The Structural (Linear Static) guide panel is displayed.

-

Select the Inertia Relief checkbox and then click

OK.

-

On the Structure ribbon, click the Run Analysis

button in the

Analyze tool group.

button in the

Analyze tool group.

-

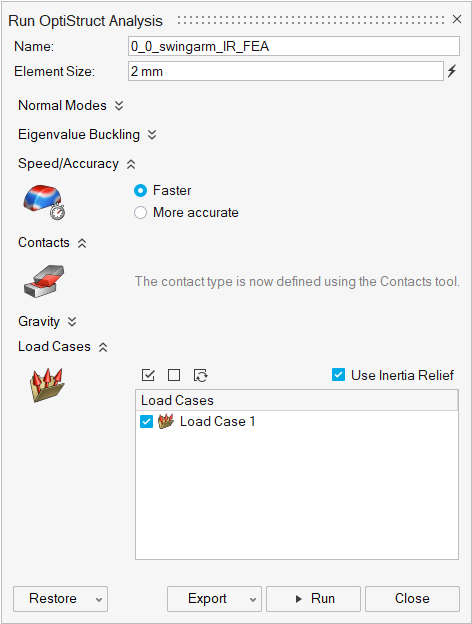

Run the analysis using the following settings:

- Change the Element size to 3.0 mm.

- Set Speed to Faster.

- Select the Linear Static 1 load case.

- Click Run to perform the analysis.

-

When the run is complete, select it in the Run Status window and click

View Now to view the results.

Tip: You can also double-click the Results icon in the Model Browser to view results for a load case.

-

In the Analysis Explorer, select von Mises Stress from

the Result Types dropdown.

Note: Even without supports, the analysis runs as any imbalance in the loads is reacted by the inertia forces.