The elastic-plastic behavior of isotropic material is modeled with user-defined

functions for work hardening curve.

The elastic portion of the material stress-strain curve is modeled using the elastic

modulus, E, and Poisson's ratio,

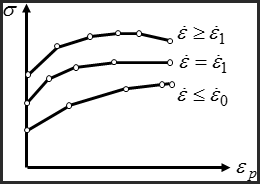

. The hardening behavior of the material is defined in function of

plastic strain for a given strain rate (Figure 1). An arbitrary number of material

plasticity curves can be defined for different strain rates. For a given strain rate, a

linear interpolation of stress for plastic strain change, can be used. This is the case of

LAW36 in Radioss. However, in LAW60 a quadratic interpolation of

the functions allows to better simulate the strain rate effects on the behavior of material

as it is developed in LAW60. For a given plastic strain, a linear interpolation of stress

for strain rate change is used. Compared to Johnson-Cook model (LAW2), there is no maximum

value for the stress. The curves are extrapolated if the plastic deformation is larger than

the maximum plastic strain. The hardening model may be isotropic, kinematic or a combination

of the two models as described in Cowper-Symonds Plasticity Model (LAW44). The material failure model is the same as in Zhao law.

For some kinds of steels the yield stress dependence to pressure has to be incorporated

especially for massive structures. The yield stress variation is then given

by:

(1)

Where,

is the pressure defined by

Stresses in Solids,

Equation 2. Drucker-Prager model described in

Drucker-Prager (LAW10 and LAW21) gives a nonlinear function for

. However, for steel type materials where the dependence to

pressure is low, a simple linear function may be considered:

(2)

Where,

-

- User-defined constant

-

- Computed pressure for a given deformed configuration

The principal strain rate is used for the strain rate definition:

(3)

For strain rate filtering, refer to Strain Rate Filtering.