Internal Stress Calculation

Global Formulation

The time integration of stresses has been stated earlier (Stress Rates) as:

The stress rate is comprised of two components:

- Stress rate due to the rigid body rotational velocity

- Jaumann objective stress tensor derivative

The correction for stress rotation from time to time is given by 1:

Where, is the rigid body rotational velocity tensor (Kinematic Description, Equation 14).

The Jaumann objective stress tensor derivative is the corrected true stress rate tensor without rotational effects. The constitutive law is directly applied to the Jaumann stress rate tensor.

Deviatoric stresses and pressure (Stresses in Solids) are computed separately and related by:

- Deviatoric stress tensor

- Pressure or mean stress - defined as positive in compression

- Substitution tensor or unit matrix

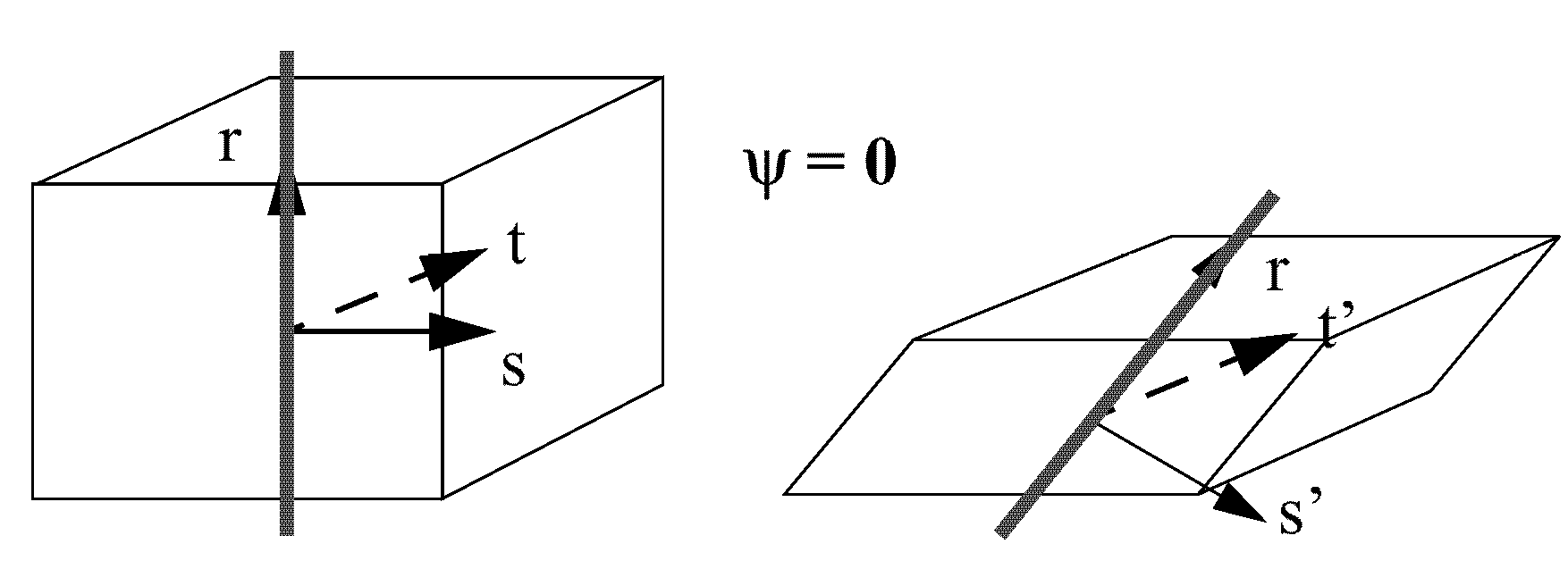

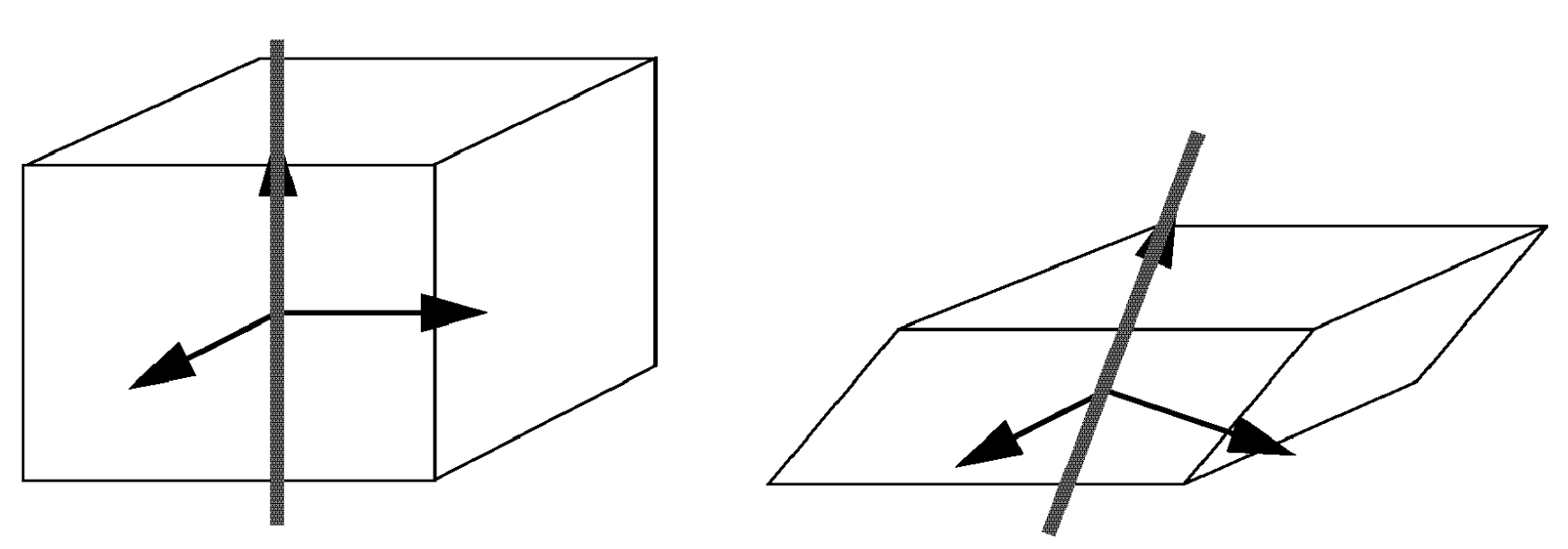

Co-rotational Formulation

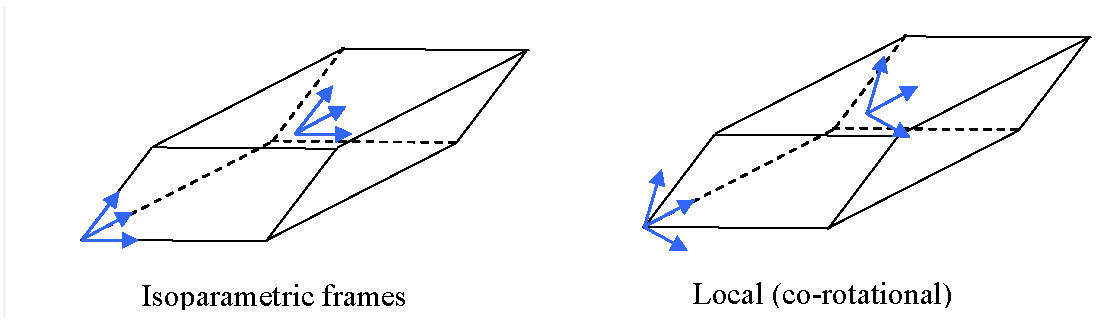

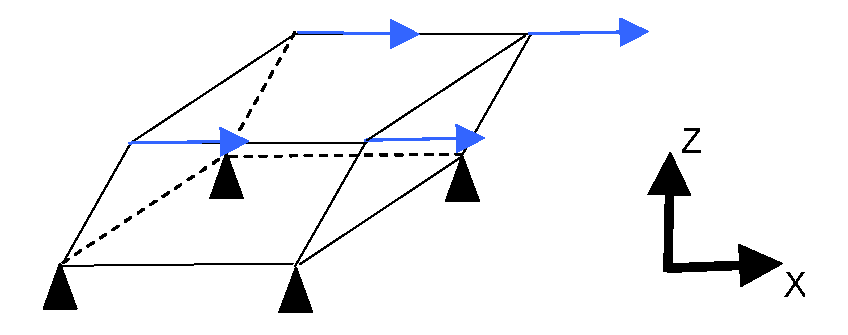

A co-rotational formulation for bricks is a formulation where rigid body rotations are directly computed from the element's node positions. Objective stress and strain tensors are computed in the local (co-rotational) frame. Internal forces are computed in the local frame and then rotated to the global system.

So, when co-rotational formulation is used, Deviatoric Stress Calculation, Equation 2 reduces to:

Where, is the Jaumann objective stress tensor derivative expressed in the co-rotational frame.

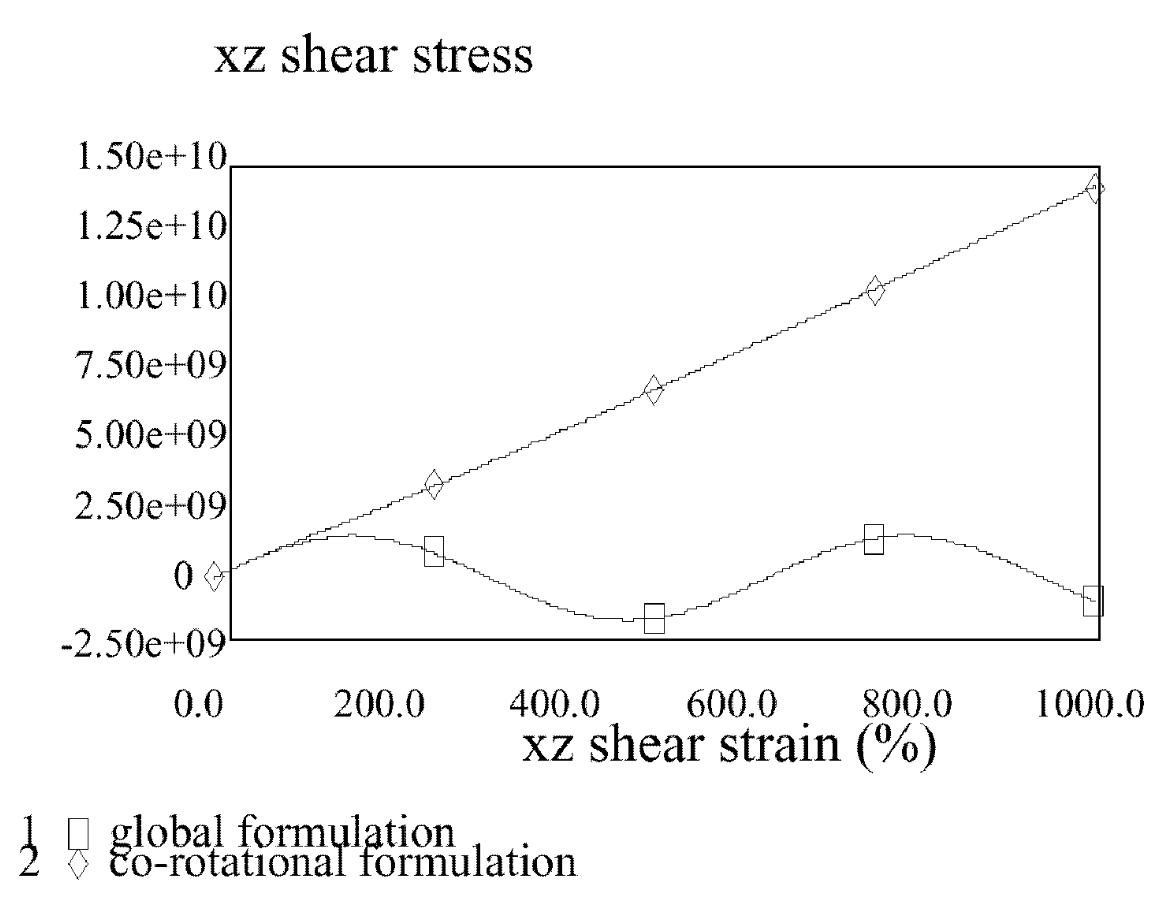

When large rotations occur, this formulation is more accurate than the global formulation, for which the stress rotation due to rigid body rotational velocity is computed in an incremental way.

The increment of the rigid body rotation vector during time step is:

So,

Where, equals the imposed velocity on the top of the brick divided by the height of the brick (constant value).

Due to first order approximation, the increment of stress due to the rigid body motion is:

Increment of stress due to the rigid body motion:

Increment of shear stress due to the rigid body motion:

Increment of shear strain:

Increment of stress due to strain:

and increment of shear stress due to strain is:

Where, is the shear modulus (material is linear elastic).

From Equation 8 to Equation 12, you have:

System Equation 13 leads to:

So, it is recommended to use co-rotational formulation, especially for visco-elastic materials such as foams, even if this formulation is more time consuming than the global one.

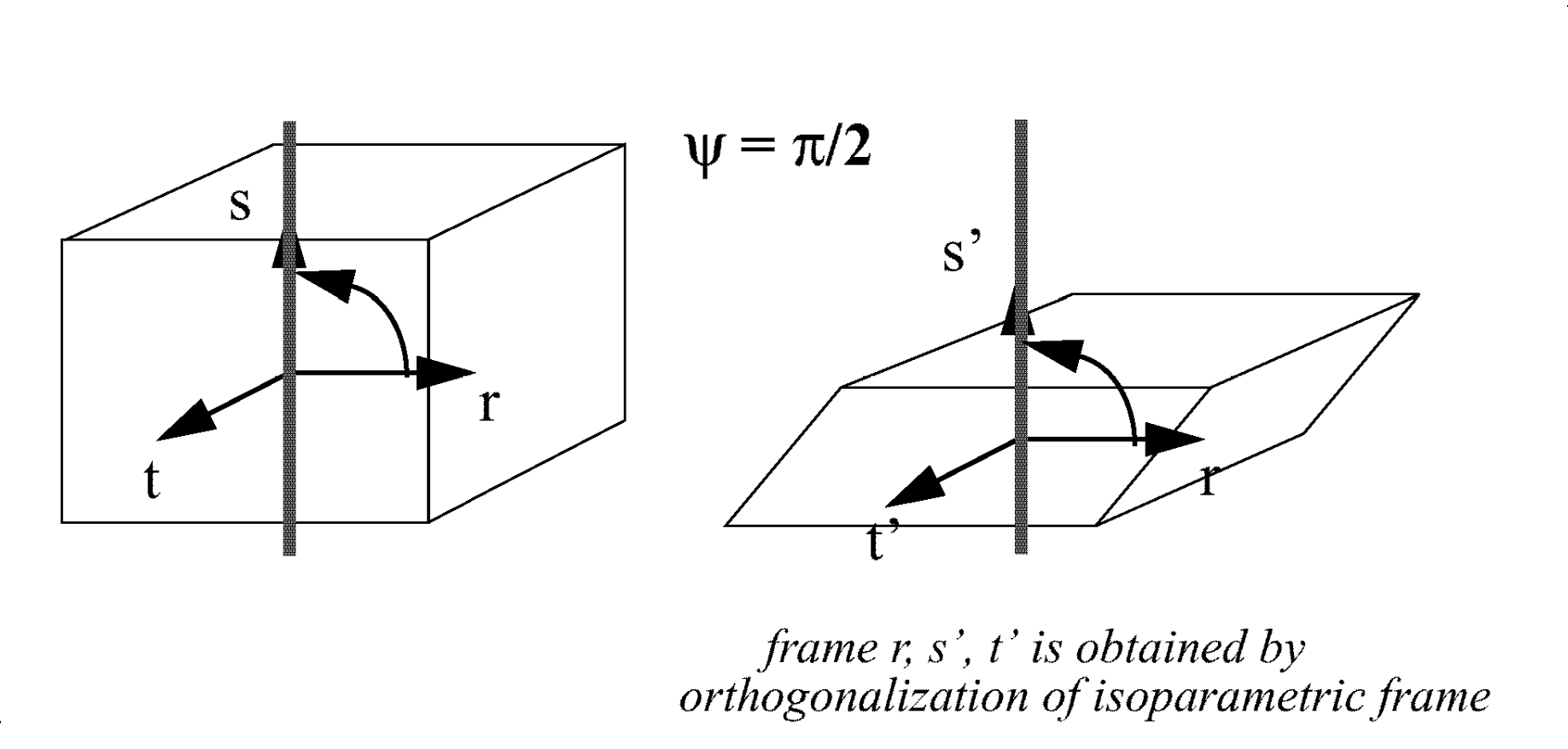

Co-rotational Formulation and Orthotropic Material

Calculation of elastic plastic flowLLNL, University of California UCRL-7322, 1981.