/PROP/TYPE22 (TSH_COMP)

Block Format Keyword This property set is used to define the composite thick shell property set.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /PROP/TYPE22/prop_ID/unit_ID or /PROP/TSH_COMP/prop_ID/unit_ID | |||||||||

| prop_title | |||||||||

| Isolid | Ismstr | Icstr | Inpts | Iint | dn | ||||

| qa | qb | ||||||||

| VX | VY | VZ | skew_ID | Iorth | Ipos | ||||

| Ashear | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| ti/t | Zi | mat_IDi | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Vdef_min | Vdef_max | APS_max | COL_min | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| prop_ID | Property

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| prop_title | Property

title. (Character, maximum 100 characters) |

|

| Isolid | Solid elements formulation flag.

(Integer) |

|

| Ismstr | Small strain formulation

flag. 4

(Integer) |

|

| Icstr | Constant stress

formulation flag. Only valid for Isolid =

14.

(Integer) |

|

| Inpts | Number of integration

points. 2

(Integer) Where,

|

|

| Iint | Number of layers when 9

< number of layers ≤ 200. Only valid for Isolid =

14. 4 (Integer) |

|

| dn | Numerical damping for

stabilization. Only valid for Isolid =

15. Default = 0.1 (Real) |

|

| qa | Quadratic bulk

viscosity. Default = 1.10 (Real) Default = 0.0 for /MAT/LAW70 |

|

| qb | Linear bulk

viscosity. Default = 0.05 (Real) Default = 0.0 for /MAT/LAW70 |

|

| Ashear | Shear factor. Default = 1.0 (Real) |

|

| VX | X component for reference

vector. Default = 1.0 (Real) |

|

| VY | Y component for reference

vector. Default = 0.0 (Real) |

|

| VZ | Z component for reference

vector. Default = 0.0 (Real) |

|

| skew_ID | Skew identifier. If the local skew has been defined, its X-axis replaces the reference vector (VX, VY, and VZ will be ignored). (Integer) |

|

| Iorth | Orthotropic system

formulation flag for reference vector.

(Integer) |

|

| Ipos | Layer positioning flag for

reference vector.

(Integer) |

|

| Angle for layer

I. (Real) |

||

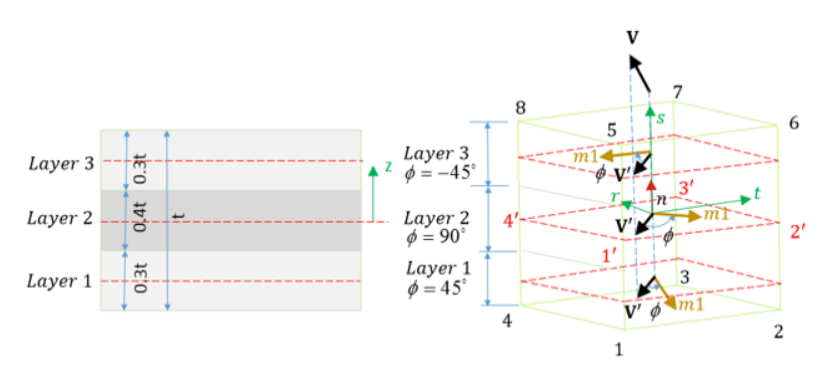

| ti/t | Relative thickness of

layer i.

(Real) |

|

| Zi | Z position (normalized by

the thickness) of layer i (-0.5 ≤

Zi ≤

0.5). Default = 0.0 (Real) |

|

| mat_IDi | Material identifier for

layer I. (Integer) |

|

| Minimum time

step. Default = 106 (Real) |

||

| Vdef_min | Minimum volume ratio

(V/Vo) to delete solid element. Default = 0 |

|

| Vdef_max | Maximum volume ratio

(V/Vo) to delete solid element. Used only if different from 0. Default = 0 |

|

| ASP_max | Maximum aspect ratio to

delete solid element. Used only if different from 0. Default = 0 |

|

| COL_min | Minimum collapse value to

delete solid element. Default = 0 |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. LOCAL_UNIT_SYSTEm:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/2

unit for prop

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. GEOMETRICAL SETS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE22/1/2

TSH_COMP example

# Isolid Ismstr Icstr Inpts Iint dn

14 0 010 333 0 0

# q_a q_b

0 0

# Vx Vy Vz skew_ID Iorth Ipos

1 -1 1 0 0 0

# Ashear

0

# PHI_I T_I/T ZI MAT_I

45 0.3 0 1

90 0.4 0 2

-45 0.3 0 1

# deltaT_min vdef_min vdef_max ASP_max COL_min

0 0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- Isolid - Solid formulation

- Isolid =14 formulation (H8 element) must use constant stress formulation (Icstr > 0), which refers to local isoparametric orthogonolized system r-s-t. Definition of the system is described in the comments of /PROP/TYPE6 (SOL_ORTH).

- When using Isolid=15 with pentahedron elements, /PENTA6 elements are recommended but degenerated /BRICK elements can also be used.

- Number of layers.

- For Isolid =

14 formulation (HA8 element), number of layers (

< 9 ) is defined as:

- If Icstr = 001, the number of layers in t direction is equal to k value from Inpts field.

- If Icstr = 010, the number of layers in s direction is equal to j value from Inpts field (Icstr = 010; Inpts = 282; for a number of 8 layers in s direction).

- If Icstr = 100, the number of layers in r direction is equal to i value from Inpts field.

- For Isolid formulation

(HA8 element) when the number of layers > 9 is defined as:

- Use Iint for Isolid

formulation (HA8 element) when the number of layers > 9.

In this case, the thickness direction integration points defined by Inpts should be zero.

Example, Icstr = 010; Inpts = 202; Iint = 100 for a number of 100 layers in "s" direction.

- Use Iint for Isolid

formulation (HA8 element) when the number of layers > 9.

- For Isolid =

14 formulation (HA8 element), number of layers (

< 9 ) is defined as:

- When using the automatic setting option Ismstr = Icpre = Iframe=-1, the values for these options are defined using the best options based on the element formulation, element type, and material. Alternatively, defining Ismstr = Icpre = Iframe=-2 will overwrite the values for these options defined in this property with the best value (refer to /DEF_SOLID) based on element type and material law. To see the values defined by Radioss, review the “PART ELEMENT/MATERIAL PARAMETER REVIEW” section of the Starter output file.

- Ismstr - Small strain

formulation flag.

- Starting with version 2017, Lagrangian elements whose volume becomes

negative during a simulation will automatically switch strain

formulations to allow the simulation to continue. When this occurs, a

WARNING message will be printed in the Engine output file. The following

options are supported.

Element Type Element Formulation Strain Formulation Negative Volume Handling Method /BRICK Isolid =14, 15 Full geometric nonlinearities Ismstr = 2, 4

Switch to small strain using element shape from cycle before negative volume.

- Starting with version 2017, Lagrangian elements whose volume becomes

negative during a simulation will automatically switch strain

formulations to allow the simulation to continue. When this occurs, a

WARNING message will be printed in the Engine output file. The following

options are supported.

- Othotropy in local

coordinate system.

- The thick shell orthotropy is planar and the third orthotropy direction is coincident with the normal to the shell plane.

- Global vector or skew_ID is used to define the orthotropy direction. The global vector or the -axis of specified skew (in this case, global vector is ignored) is projected to the mean plane of soslid element.

- For Isolid=14, the mean plane of the element depends on Icstr.

- r-s for Icstr=001

- r-t for Icstr=010

- s-t for Icstr=001.

- is the angle (in degrees) between the first direction of orthotropy and projection of reference vector on the shell mean plane for layer i.

- Material used for

layer

- Material law type used in Mat_IDi can be different for each layer.

- For Isolid= 15, the material law number defined in /PART will be used to compute the contact interface stiffness and the hourglass stresses.