OS-T: 1560 3-Point Bending using RBODY

This tutorial demonstrates RBODY which is used in this nonlinear large displacement implicit analysis involving contacts using OptiStruct.

- Import the model into HyperMesh

- Set up of contacts and RBODY

- Set up nonlinear analysis

- View the results in HyperView

Launch HyperMesh and Set the OptiStruct User Profile

-

Launch HyperMesh.

The User Profile dialog opens.

-

Select OptiStruct and click

OK.

This loads the user profile. It includes the appropriate template, macro menu, and import reader, paring down the functionality of HyperMesh to what is relevant for generating models for OptiStruct.

Open the Model

- Click .

- Select the 3Point_Bending_RBODY.hm file you saved to your working directory.

-

Click Open.

The 3Point_Bending_RBODY.hm database is loaded into the current HyperMesh session, replacing any existing data.

Set Up the Model

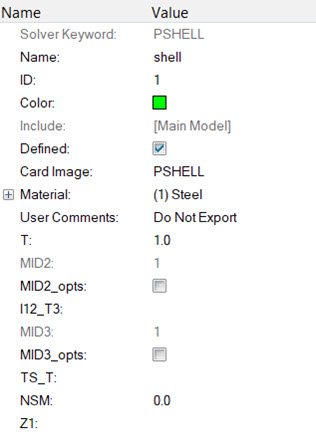

Create the Properties

-

In the Model Browser, right-click and select from the context menu.

A default PSHELL property displays in the Entity Editor.

- For Name, enter Shell.

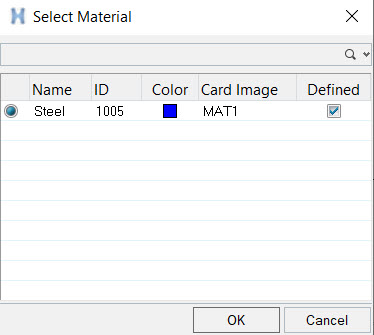

- For Material, click .

-

In the Select Material dialog, select

Steel and click OK.

Figure 2. Select material steel for the Property shell

-

For T (thickness of the plate), enter 1.

Figure 3. Property Values for Shell

A new property, Shell, has been created as a 2D PSHELL. -

In the Model Browser, click on the component

Fixed Cylinder1.

The component fields display in the Entity Editor.

- For Property, click .

-

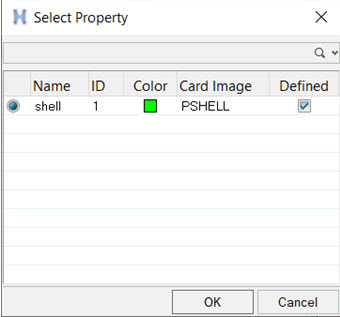

In the Select Property dialog, select

Shell and click OK.

The component Fixed Cylinder1 has been updated with a property of the same name and is currently the “Current Component” (see the box in the lower right for Fixed Cylinder1). This component uses the Shell property definition with a thickness value of 1.0. The material Shell is referenced by this component.

Figure 4. Select Property Shell for the Component Fixed Cylinder1

- Similarly, assign the Shell property to the other components.

Create the Sets

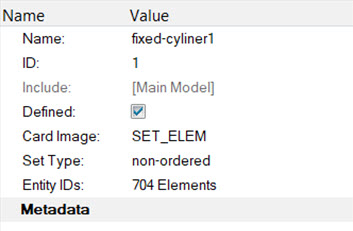

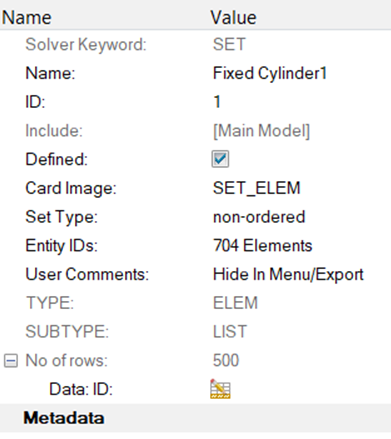

- In the Model Browser, right-click and select from the context menu.

- For Name, enter Fixed Cylinder1.

- Right-click on the component Fixed Cylinder1 and select Isolate Only.

-

Click on the Entity IDs to select the elements

contributing to the set.

Figure 5. Select the Elements for the Set corresponding to Fixed_Cylinder1

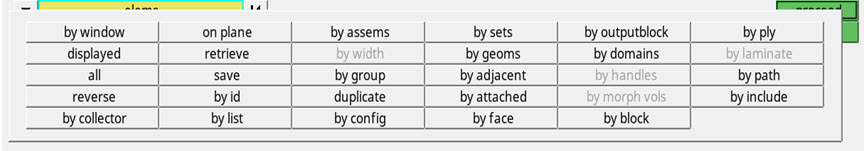

The Selection panel opens. -

Click .

This selects all the elements corresponding to the component Fixed_Cylinder1.

Figure 6. Element Selection Panel

- Click proceed.

- Similarly, create sets named Fixed Cylinder2 and Pressing Cylinder.

Create the Rigid Bodies

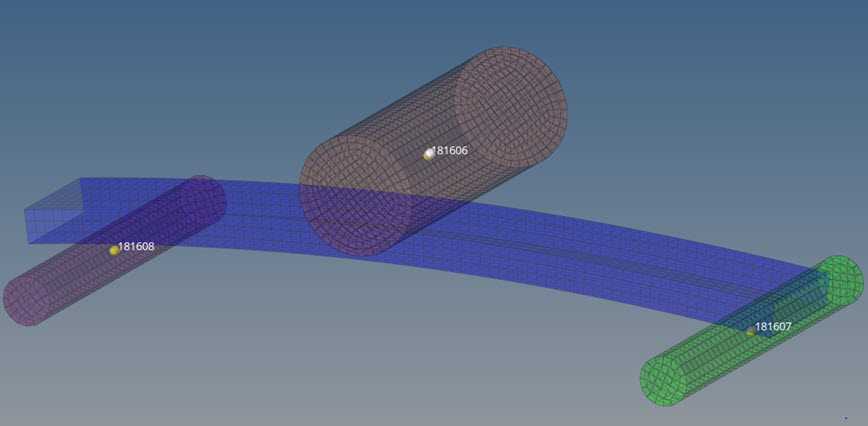

In this step, you will define the components Fixed Cylinder1, Fixed Cylinder2 and Pressing Cylinder as rigid bodies.

- In the Model Browser, right-click and select from the context menu.

- For Name, enter Fixed Cylinder1.

-

In the Entity Editor, click on Reference

Node and select the node 181607.

Tip: Switch the model to wireframe to locate the node.

- For Element Sets, select Small_Cylinder1.

- Similarly, repeat the above steps to create rigid bodies for Fixed Cylinder2 and Pressing Cylinder.

- For Fixed Cylinder2, select reference node 181608.

- For Pressing Cylinder, select reference node 181606.

Create Set Segments

The set segments will be defined, which will be used later to define the contact groups.

- In the Model Browser, right-click and select from the context menu.

- For Name, enter Fixed Cylinder1.

-

Click Entity IDs to select the elements corresponding to

Fixed Cylinder1 that are in contact with the Bumper

Beam.

Note: Make sure to switch the selection panel from faces to elements.

Figure 7.

- Similarly, create the set segments for Fixed Cylinder2, Pressing Cylinder and Bumper Beam.

Create Contact Groups

Here the contact groups will be defined.

- In the Model Browser, right-click and select from the context menu.

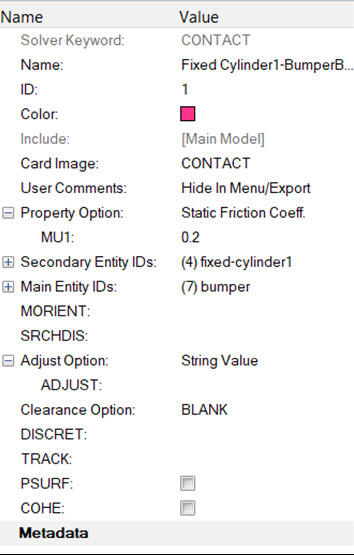

- For Name, enter Fixed Cylinder1-BumperBeam.

- For Card Image, select CONTACT.

- Select the set segment created earlier for the Fixed Cylinder1 as the Secondary Entity IDs and the set segments for the Bumper Beam that is in contact with pressing cylinder as Main Entity IDs.

- For Property Option, select Static Friction Coeff. from the drop-down.

- For MU1(Coefficient of static friction), enter 0.2.

-

Similarly, create the contact group between the Fixed Cylinder2-

Bumper Beam and Pressing Cylinder- Bumper

Beam.

Figure 8. Create a set segment

Apply Loads and Boundary Conditions

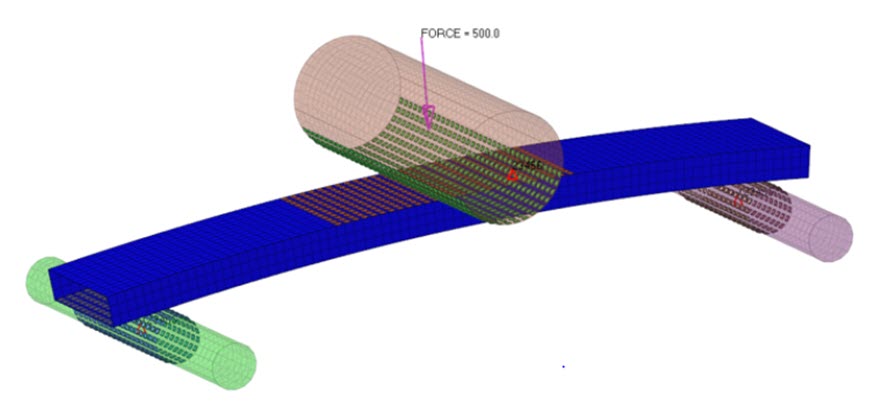

In the following steps, you will constrain the nodes 181607 and 181608 in all degrees of freedom and 181606 in all, except x direction. A force of 500N is applied on the node 181606. Other load collectors required for Nonlinear analysis are also defined.

Create SPC Load Collector

-

In the Model Browser, right-click and select from the context menu.

A default load collector displays in the Entity Editor.

- For Name, enter spcs.

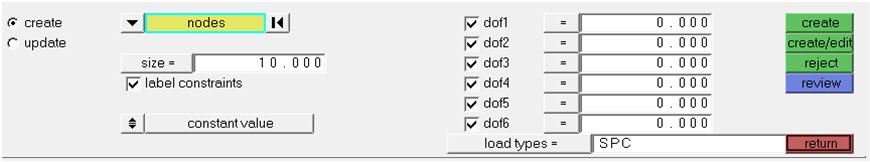

- Click to open the Constraints panel.

- Select the nodes 181607 and 181608.

-

Constrain all dof and enter a value of 0.0 to all.

Figure 9. Constrain all Degrees of Freedom of the Selected Nodes

-

Click create.

This applies the constraints to the selected nodes.

- Similarly select the node 181606 and deselect dof1 so that a load can be applied in the x-direction.

- Click create.

Create Force Load Collector

This step will outline how to apply the force.

- In the Model Browser, right-click and select from the context menu.

- For Name, enter Forces.

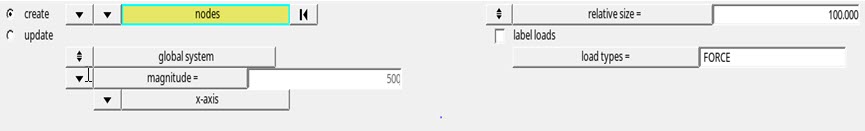

- Click to open the Force panel.

-

Select node 181606.

Figure 10. Select a Circular (Inside of Circle) Selection Window

- For coordinate system, toggle global system.

- Click the vector definition switch and select constant vector.

- For magnitude =, enter 500.

-

Click the direction definition switch below magnitude =,

and select x-axis from the pop-up menu.

Figure 11. Assign Direction and Magnitude to the Forces

-

Click create.

This creates point forces, with the given magnitude in the x-direction, to be applied to the node 181606.

- Click return to go the main menu.

Create TABLED1 Curve

- In the Model Browser, right-click and select .

- For Name, enter TABLED1.

- For Card Image, select TABLED1 from the drop-down menu.

-

In the Model Browser, right-click on the

TABLED1 curve and select Edit

enter the values:

In the x(1) field, enter 0.0

In the y(1) field, enter 1.0

In the x(2) field, enter 1

In the y(2) field, enter 1.0

-

Click Close.

The load collector TABLED1 that defines the time history of the loading has been created.

Create a TLOAD Load Step Input

- In the Model Browser, right-click and select .

- For Name, enter TLOAD.

- For Config type, select Dynamic Load – Time Dependent from the drop-down list.

- For Type, select the TLOAD1 from the drop-down.

- For EXCITEID , click .

- In the Select Loadcol dialog, select Force from the list of load collectors.

- For TID, select TABLED1.

- Click Close.

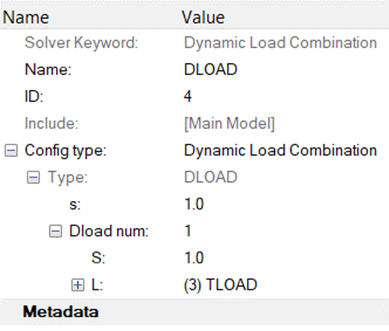

Create a DLOAD Load Step Input

- In the Model Browser, right-click and select .

- For Name, enter DLOAD.

- For Config type, select Dynamic Load Combination from the drop-down list.

- For Type, DLOAD is the default.

- For S (scale factor), enter 1.0.

-

For L, select TLOAD load step input created above.

Figure 12.

- Click Close.

Create TSTEP Load Collector

- In the Model Browser, right-click and select .

-

For Name, enter TSTEP.

- Click Color and select a color from the color palette.

- For Card Image, select TSTEP from the drop-down menu.

- For TSTEP_NUM, enter 1 and press Enter.

- For N, enter the number of time steps as 100.

- For DT, enter the time increment of 0.1.

- For W4, enter 3e-5.

- Click Close.

Create NLPARM Load Step Input

- In the Model Browser, right-click and select .

- For Name, enter NLPARM.

- Click Color and select a color from the color palette.

-

For Config type, select Nonlinear Parameters.

Type default is NLPARM.

- For NINC, enter 10.

- For DT, enter 0.1.

- For CONV, select UP.

- For TTERM, enter 0.9.

Create NLADAPT Load Step Input

- In the Model Browser, right-click and select .

- For Name, enter NLADAPT.

- For Config type, select Time step Parameters.

- For Type, the default is NLADAPT.

- For DTMAX, enter 0.1.

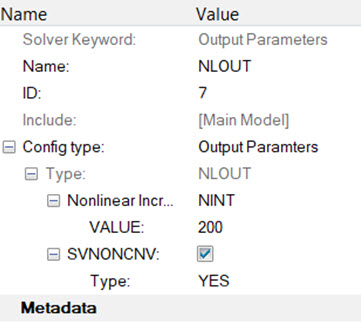

Create NLOUT Load Step Input

- In the Model Browser, right-click and select .

- For Name, enter NLOUT.

- For Config type, select Output Parameters.

- For Type, the default is NLOUT.

- For NINT, enter 200.

-

Activate SVNONCNV.

Figure 13. Create NLOUT Card

Create CNTSTB Load Collector

-

In the Model Browser, right-click and select from the context menu.

A default load collector displays in the Entity Editor.

- For Name, enter CNTSTB.

- For Card Image, select CNTSTB.

- For S0, enter 0.01

Define Output Control Parameters

- From the Analysis page, select control cards.

- Click on GLOBAL_OUTPUT_REQUEST.

- Below DISPLACEMENT, ELFORCE, STRESS and STRAIN, set Option to Yes.

- Click return twice to go to the main menu.

Activate PARAM Control Cards

- From the Anaysis page, select Control Cards.

- For Control Cards, select PARAM.

- Activate HASHASSM, NLMON, and UNSYMSLV, enter YES.

- Activate LGDISP, enter 1.

Create NLGEOMETRY Load Step

-

In the Model Browser, right-click and select .

A default load collector displays in the Entity Editor

- For Name, enter NLGEOMETRY.

-

In the Select Loadcol dialog, select

SPC from the list of load step inputs and click

OK.

This selects the boundary conditions created above.

-

In the Select Loadcol dialog, select

DLOAD from the list of load collectors and load step

inputs and click OK.

This selects the boundary conditions created above.

- Similarly, select the TSTEP, NLPARM, NLADAPT, and NLOUT, and assign respective load collectors and load step inputs.

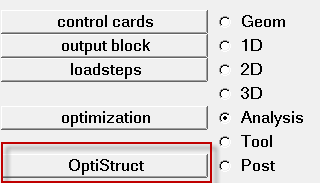

Submit the Job

-

From the Analysis page, click the OptiStruct

panel.

Figure 14. Accessing the OptiStruct Panel

- Click save as.

- In the Save As dialog, specify location to write the OptiStruct model file and enter 3Point_Bending_RBODY.hm for filename.

-

Click Save.

The input file field displays the filename and location specified in the Save As dialog.

- Set the export options toggle to all.

- Set the run options toggle to analysis.

- Click OptiStruct to submit the job.

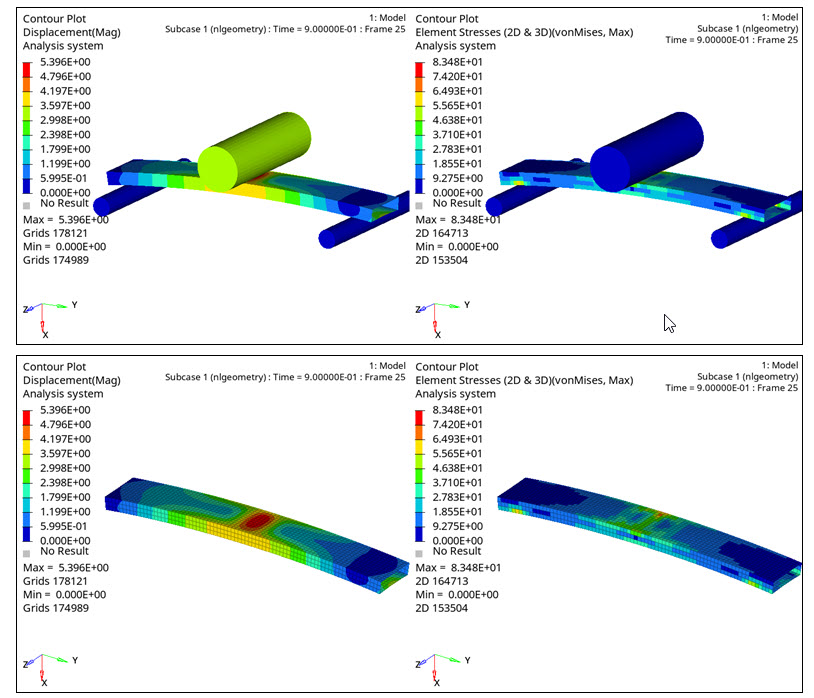

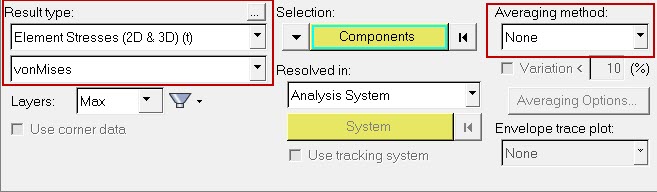

View the Results

- Once you receive the message Process completed successfully in the command window, click HyperView.

- Open the results and plot the displacement and the von Mises stress contour at 100% load.

-

On the toolbar, click

(Contour).

(Contour).

- Under Result type, from the first drop-down menu, select Element Stresses (2D & 3D)(t).

-

Under Result type, from the second drop-down menu, select

vonMises.

Figure 15. Contour Panel

-

Verify that the fields in the Contour panel match those in

Figure 15 and click

Apply.

Figure 16. Displacement and Stress Result for the Analysis