Turbulated Tube

Description

- Type

- Mixed Laminar-Turbulent Duct Nu

- Subtype

- Turbulated Tube

| Index | UI Name (.flo label) | Description |

|---|---|---|

| 1 | Turbulator Correlation (TURB_CORL) | The HTC equation to use. 1: Webb Circ Tube 2: TS Ravi Circ Tube 3: Han 90 deg, 2-sided rect 4: Han Angled, 2-sided rect |

| 2 | Flow Element (FLOW_ELM) | ID for the flow element that will be used for the mass flow

rate and other correlation inputs. If AUTO, the correlation must be applied to a convector that is connected to a fluid chamber that has only one flow element entering this chamber. The ID of this flow element will be used. The element can be of almost any type, although some types will not have geometric inputs that can be obtained with the AUTO option of the remaining inputs. |

| 3 | Hydraulic Diameter (HYD_DIA) | Passage hydraulic diameter. If AUTO, the hydraulic diameter of the flow element from input 2 will be used. |

| 4 | Flow Area (FLOW_AREA) | Passage flow area. If AUTO, the area of the flow element from input 2 will be used. If the area from the flow element is not available, the passage will be assumed circular, and the hydraulic diameter will be used to calculate the area. |

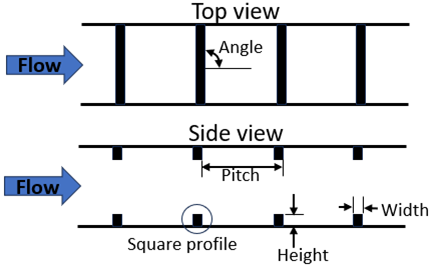

| 5 | Rib Height (RIB_HEIGHT) | Perpendicular distance from the wall surface to the tip of the rib. |

| 6 | Rib Width (RIB_WIDTH) | Distance between the sides of the rib. Usually, this is the

same as the Rib Height and most correlations assume it is the

same. If AUTO, the width will be set equal to the height. |

| 7 | Rib Pitch (RIB_PITCH) | The distance between the ribs in the flow direction. |

| 8 | Rib Angle (RIB_ANGLE) | The angle between the rib and the flow direction. 90 degrees means the rib is perpendicular to the flow. Typical angles are between 45 and 90 degrees. |

| 9 | Rib Profile (RIB_PROFILE) | The rib shape. 1: Circle 2: Semicircle 3: Triangular 4: Square (default) |

| 10 | Rectangle Side w Ribs (RIB_SIDE) | The correlations based on Han have ribs on two sides of a

rectangle. This input specifies if the ribs are on the short or

long side of the rectangle. 1: Short Side 2: Long Side |

| 11 | Inlet Effects (INLET_EFF) | Option for heat transfer inlet effects. 1: No inlet effects. 2: Abrupt local or uniform average inlet effects. 3: Abrupt average inlet effects. 4: Uniform local inlet effects. 5: Between uniform average and local inlet effects 6: Between abrupt average and local inlet effects. |

| 12 | Entrance Length (ENTR_LEN) | Distance from the start of the heat transfer area to the

boundary layer start. Used in the inlet effects

calculation. If AUTO, the length of the flow element from input 1 will be used. |

| 13 | Laminar-to-Transition Re (RE_LAM) | Reynolds number where the laminar regime of the flow ends and

the transitional regime starts. If AUTO, the global transition Re is used (default=2185). |

| 14 | Transition-to-Turbulent Re (RE_TURB) | Reynolds number where the transitional regime of flow ends

and fully turbulent regime starts. If AUTO, the global transition Re is used (default=2415). |

| 15 | HTC Multiplier (HTC_MULT) | A constant multiplier to scale the value of the heat transfer coefficient obtained from the correlation. |

Formulation

- Webb Circular Tube (ref. 1)

Limits:

- TS Ravi Circular Tube (ref 2.)

Use this correlation for circular tubes and all rib profiles listed in input 9. This correlation uses a statistical approach to correlate many experimental results. It is good for a wide range of geometries but may not be as accurate as the other correlations for geometries specific to them. This correlation calculates a multiplier to a smooth tube HTC. The Gnielinski correlation is used for the smooth duct HTC. The turbulated duct HTC is the smooth times the Hmult.

Limits:

- Han 90 deg, 2-sided rectangular tube (ref 3.)

Use this correlation for a rectangular shaped passage with ribs on 2 sides. This is for ribs that are perpendicular to the flow only.

Limits:

- Han Angled, 2-sided rectangular tube (ref 4 and 5)

Use this correlation for a rectangular shaped passage with ribs on two sides. This is for ribs that are 30 to 90 degrees (perpendicular) to the flow.

Constants and exponents depend on the rectangle aspect ratio.

For 0.25<w/h<1 (ref 4)

For 1<w/h<4 (ref 5)

Limits:

Where:

| Index | .flo Label | Description |

|---|---|---|

| 1 | TNET | Thermal network ID which has the convector where this correlation is used. |

| 2 | CONV_ID | Convector ID which is using this correlation. |

| 3 | FLOW_ELM | Flow element from input 1 or automatically selected. |

| 4 | FLOW | Mass flow rate used in the Re calculation. |

| 5 | HYD_DIA | The hydraulic diameter used in the HTC calculations. |

| 6 | PTCH/HGHT | Rib pitch/rib height. |

| 7 | HGHT/H_DIA | Rib height/hydraulic diameter. |

| 8 | PTCH/H_DIA | Rib pitch/hydraulic diameter. |

| 9 | FRIC_FANNING | Fanning friction factor. |

| 10 | INLET_HMULT | HTC multiplier due to inlet effects. |

| 11 | RE | Axial Reynolds number. |

| 12 | NU | Calculated Nusselt number. |

| 13 | HTC | Calculated Heat Transfer Coefficient. |

Heat Transfer Correlation References

- Webb, R. L., Eckert, E. R. G., and Goldstein, R. J. "Heat Transfer and Friction in Tubes with Repeated-Rib Roughness", Int. Journal of Heat and Mass Transfer, 14 (1971).

- Ravigururajan, T.S., "General correlations for pressure drop and heat transfer for single-phase turbulent flows in ribbed tubes", Iowa State Univ, Thesis, 1986.

- Han J.C., "Heat Transfer and Friction Characteristics in Rectangular Channels with Rib Turbulators", Journal of Heat Transfer, ASME (1988).

- Han, J. C., Ou, S., Park, J. S. and Lei, C. K. " Augmented Heat Transfer in Rectangular Channels of Narrow Aspect Ratios with Rib Turbulators" , International Journal of Heat Mass Transfer, 32, (1989).

- Han, J. C. and Park, J. S. "Developing Heat Transfer in Rectangular Channels with Rib Turbulators", International Journal of Heat Mass Transfer, 31, (1988).