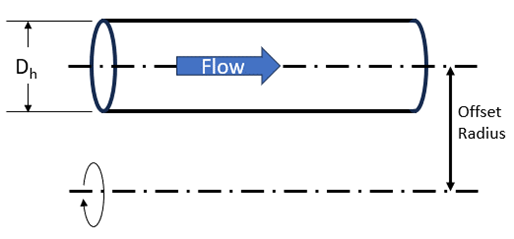

Morris Parallel Rotating Tube

Description

- Type

- Mixed Laminar-Turbulent Duct Nu

- Subtype

- Morris Parallel Rotating Tube

| Index | UI Name (.flo label) | Description |

|---|---|---|

| 1 | Flow Element (FLOW_ELM) |

The ID for the flow element that will be used for the mass

flow rate and other correlation inputs. If AUTO, the correlation must be applied to a convector that is connected to a fluid chamber that has only one flow element entering this chamber. The ID of this flow element is used. The element can be of almost any type, although some types do not have geometric inputs that can be obtained with the AUTO option of the remaining inputs. |

| 2 | Hydraulic Diameter (HYD_DIA) |

Passage hydraulic diameter. If AUTO, the hydraulic diameter of the flow element from input 1 is used. |

| 3 | Flow Area (FLOW_AREA) |

Passage flow area. If AUTO, the area of the flow element from input 1 is used. If the area from the flow element is not available, the passage is assumed circular, and the hydraulic diameter is used to calculate the area. |

| 4 | Offset Radius (OFFSET_RAD) |

Distance from the rotation centerline to the tube centerline.

If AUTO, the radius of the flow element from input 1 is used. |

| 5 | Tube Rotation Index (ROTOR_IDX) |

The index of the rotor shaft containing the RPM for this

tube. The speed for this rotor shaft is set in the tab. If AUTO, the rotation of the flow element from input 1 is used or an RPM associated with the surface thermal node is used. |

| 6 | HTC Multiplier (HTC_MULT) |

A constant multiplier to scale the value of the heat transfer coefficient obtained from the correlation. |

Formulation

This correlation uses a Nusselt number equation by Morris (reference 1) for a fully developed turbulent flow and a Nusselt number equation by Wood (reference 2) for a laminar flow. A linear interpolation is used if the Re is in the transitional regime. The turbulent Nu is not allowed to be lower than a no rotation duct flow Nu using Gnielinski’s correlation.

Axial Reynolds number:

Rotational Reynolds number, J:

Rotational Rayleigh number, Ra:

For Re <= RE_LAM (default is 2185)

For Re >= RE_TURB (default is 2415)

| Index | .flo label | Description |

|---|---|---|

| 1 | TNET | Thermal network ID which has the convector where this correlation is used. |

| 2 | CONV_ID | Convector ID which is using this correlation. |

| 3 | FLOW_ELM | Flow element from input 1 or automatically selected. |

| 4 | FLOW | Mass flow rate used in the Re calculation. |

| 5 | HYD_DIA | The hydraulic diameter used in the HTC calculations. |

| 6 | RE_AX | Axial Reynolds number. |

| 7 | RE_ROT | Rotational Reynolds number, J. |

| 8 | NU | Calculated Nusselt number. |

| 9 | HTC | Calculated Heat Transfer Coefficient. |

Heat Transfer Correlation References

- Morris, W.D. and Woods, J.L, Heat Transfer in the Entrance Region of Tubes That Rotate About a Parallel Axis, Journal of Mechanical Engineering Science, 20(6), 1978, 319-325.

- Woods, J.L and Morris, W.D., A Study of Heat Transfer in a Rotating Cylindrical Tube, ASME Journal of Heat Transfer, Nov 1980, 612-616.