The following sections describe the available heat transfer correlations (HTCs) in

Flow Simulator. Correlation equations and literature

references are included. All HTC options appear in the 1D-Thermal Convection Resistor.

In addition, the duct flow HTC options appear in the Tube/Pipe flow elements and the

Advance Orifice flow element.

| Nomenclature: |

Subscripts: |

| Nu: Nusselt Number |

lam: Laminar Regime |

| Re: Reynolds number |

turb: Turbulent Regime |

| Pr: Prandtl multiplier |

tran: Transition Regime |

: Dynamic Viscosity : Dynamic Viscosity |

|

Heat Transfer Correlations:

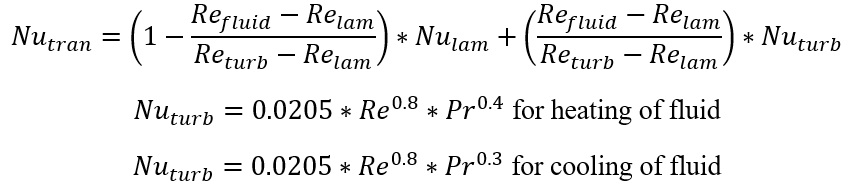

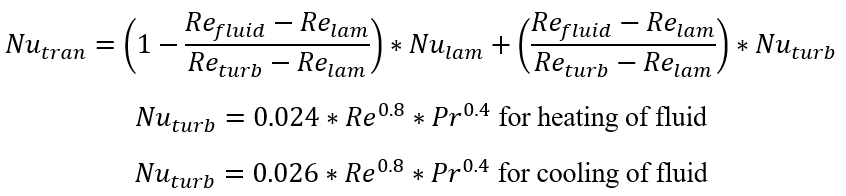

Lapides-Goldstein:

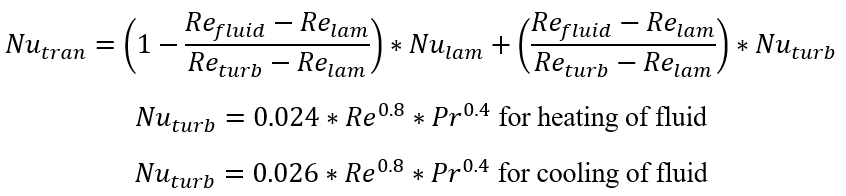

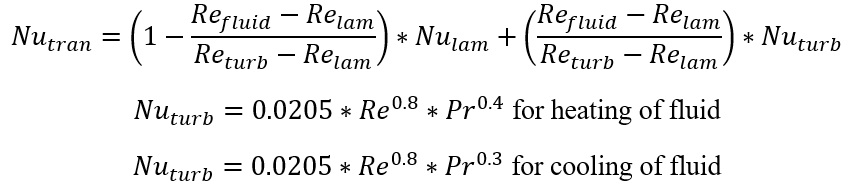

Dittus-Boelter:

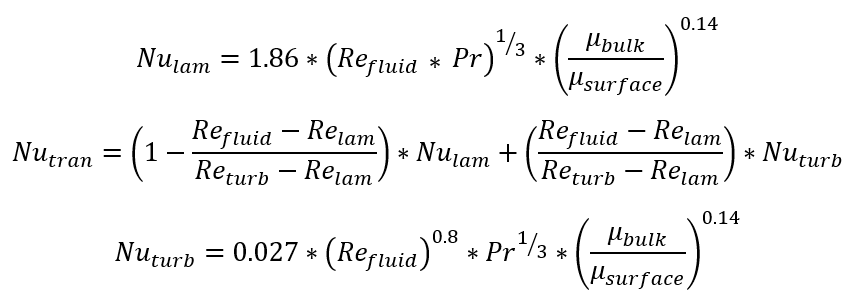

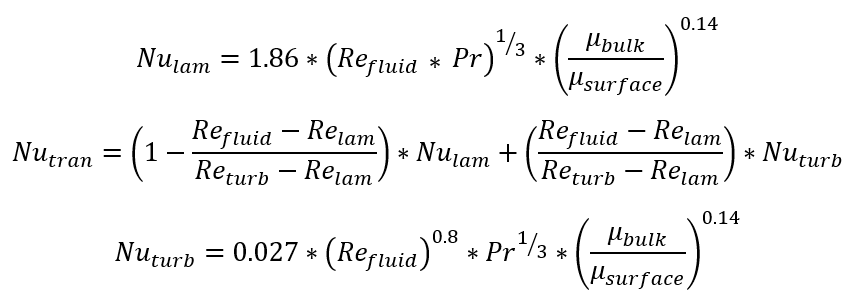

Sieder-Tate:

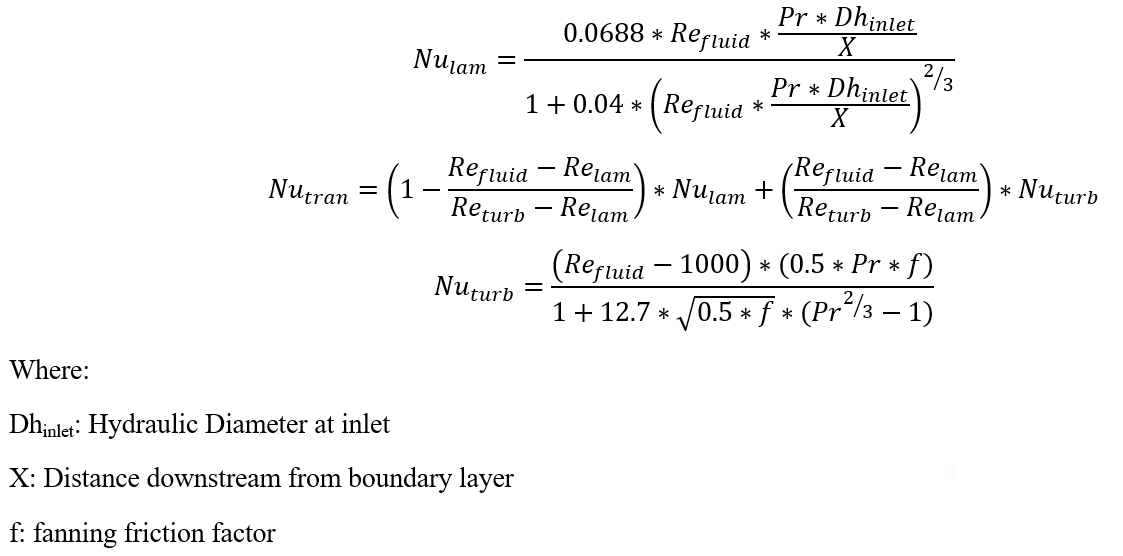

Gnielinski:

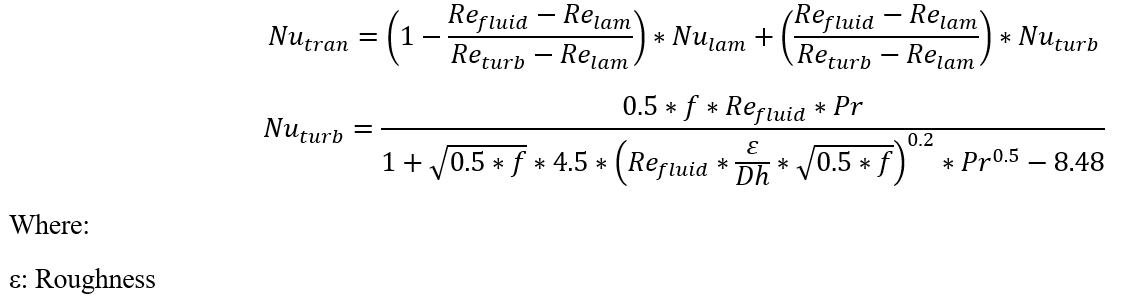

Bhatti-Shah:

External Heat Transfer:

The following section lists cross flow convection and free convection configurations that

are available in Flow Simulator. These options are

primarily used by connecting a 1D Thermal Convection Resistor to an internal chamber

in the flow path.

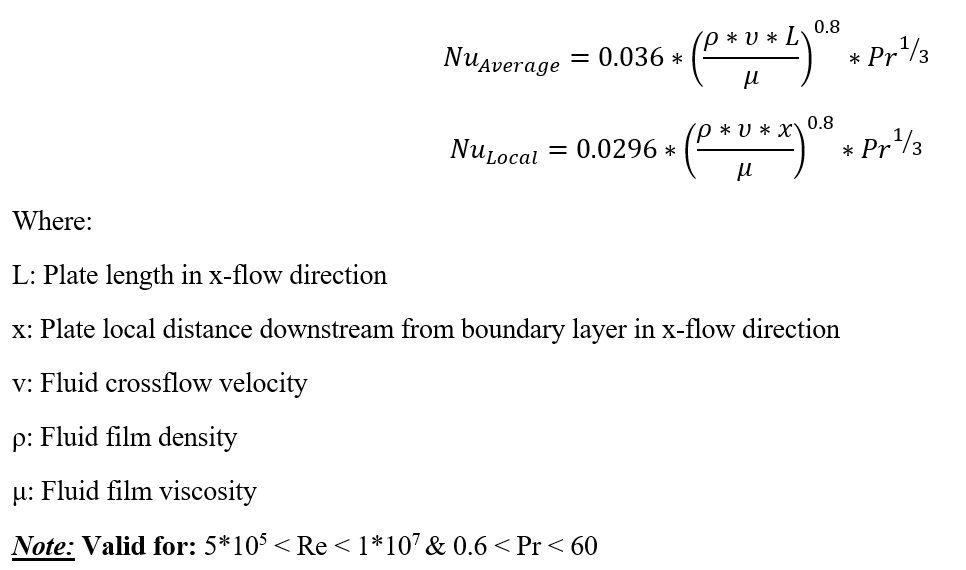

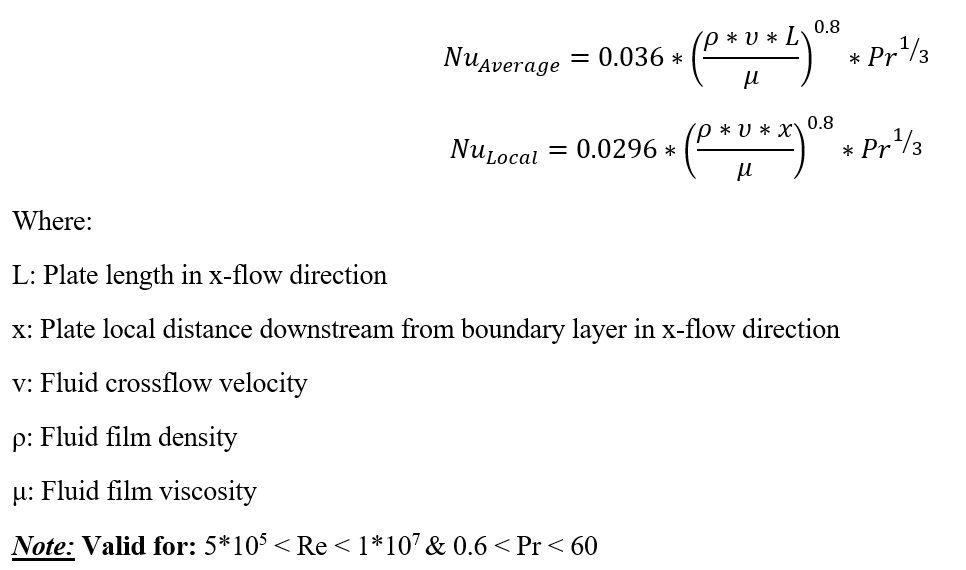

Colburn (Plate in Cross Flow):

Incropera (Plate in Cross

Flow)

The flat plate correlation based on Incropera (reference 4) calculates an average

Nusselt number for the laminar flow over the entire plate, or the mixed laminar and

turbulent flow over the plate. The plate is assumed to have a constant surface

temperature.

For Re < ~500,000:

For Re > ~500,000:

Where:

Note: Valid for 10 < Re <

108, Pr > 0.6

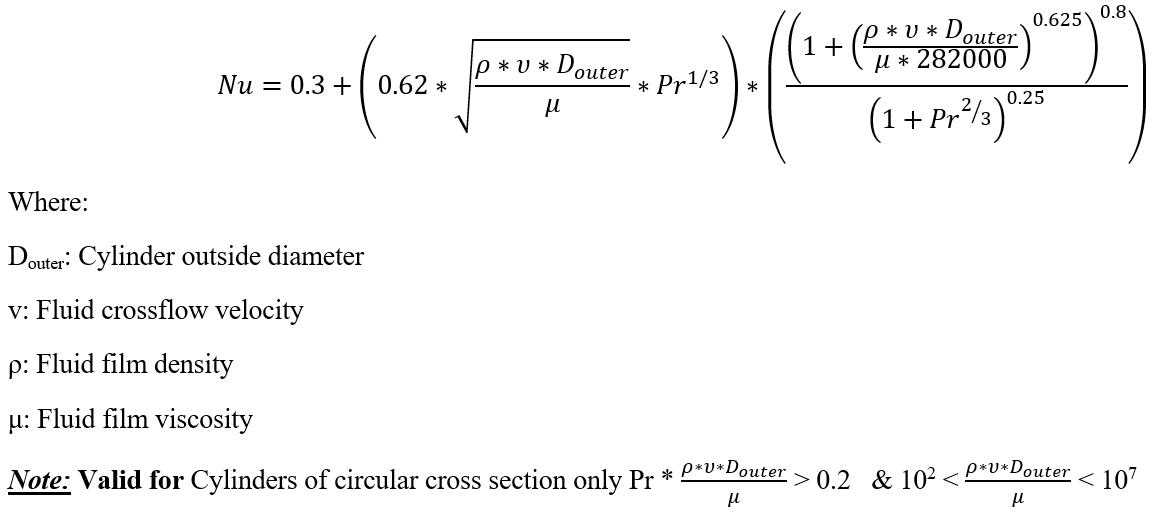

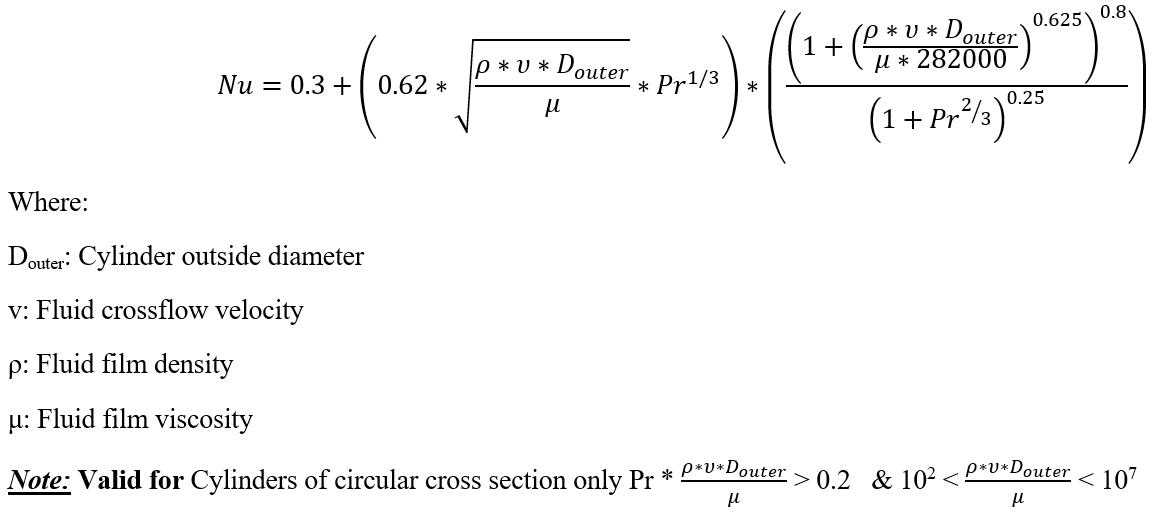

Churchill-Bernstein (Cylinder in Cross Flow):

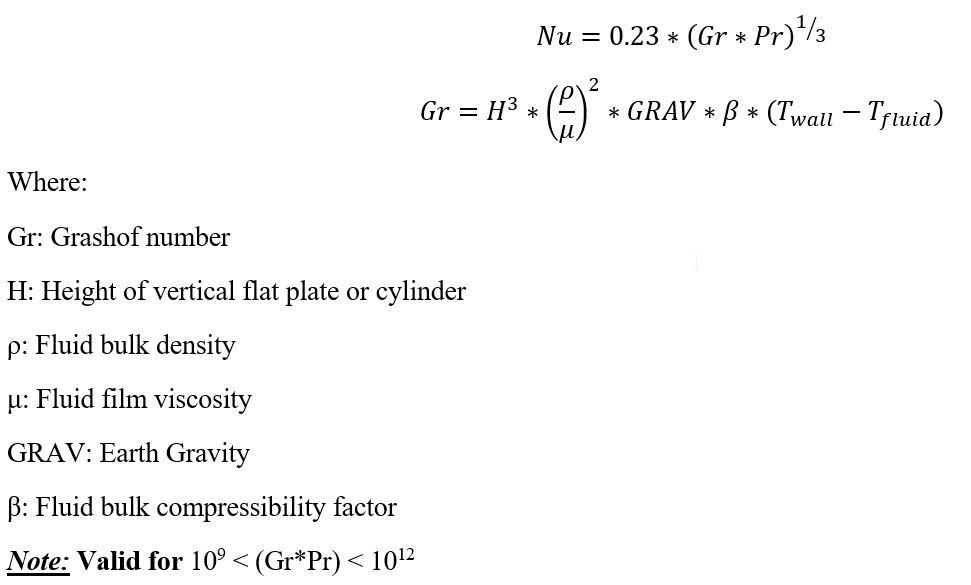

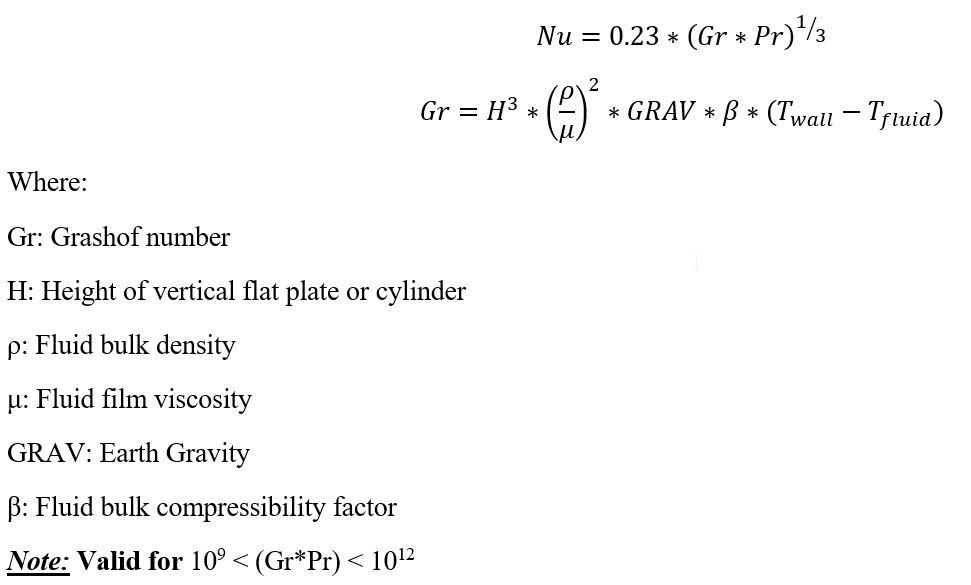

McAdams (Vertical

Prism in Free Convection):

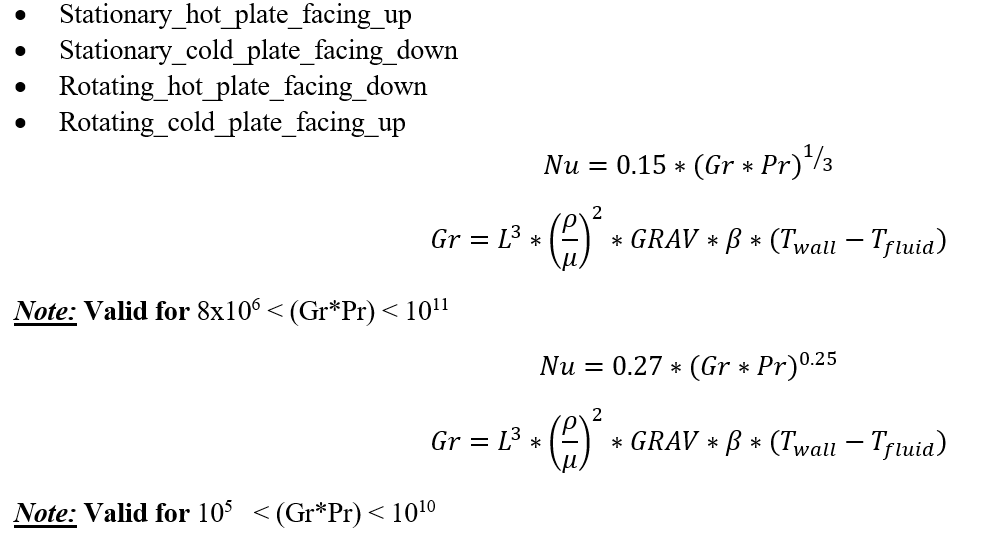

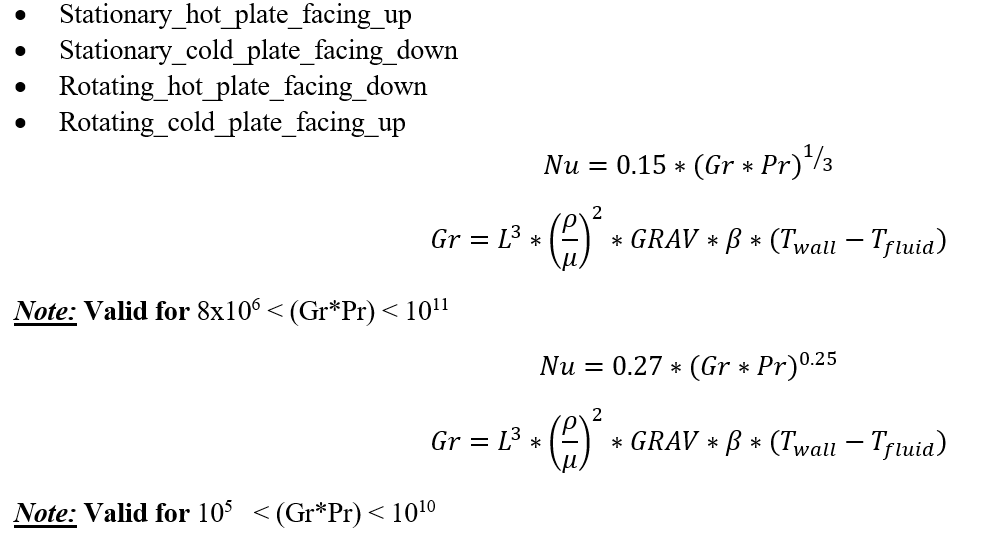

Horizontal Plate

in Free Convection:

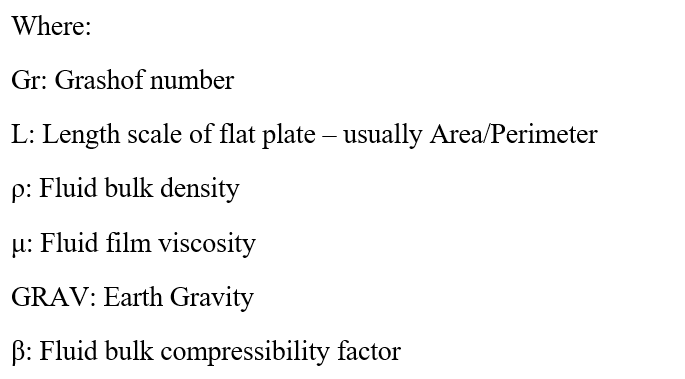

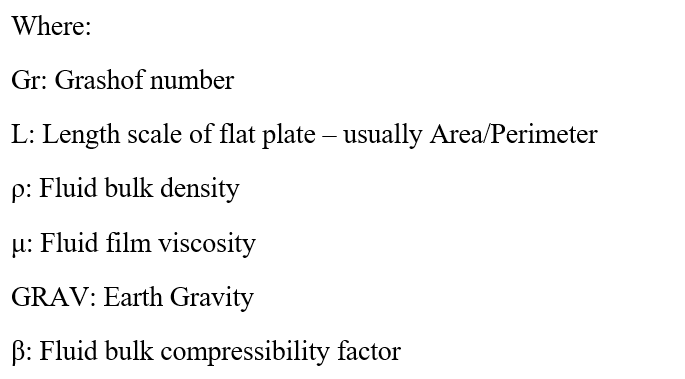

Churchill-Chu(Horizontal Cylinder in Free Convection):

Where:

Gr: Grashof number

Douter: Cylinder outside diameter

ρ: Fluid bulk density

μ: Fluid film viscosity

GRAV: Earth Gravity

β: Fluid bulk compressibility factor

Note: Valid for 106 < (Gr*Pr) <

1012

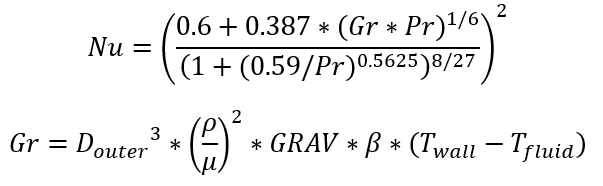

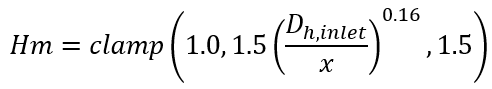

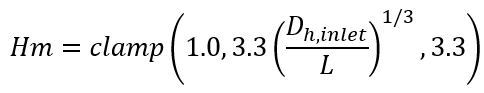

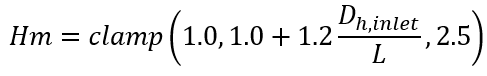

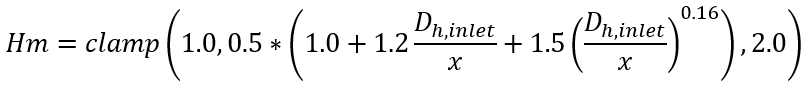

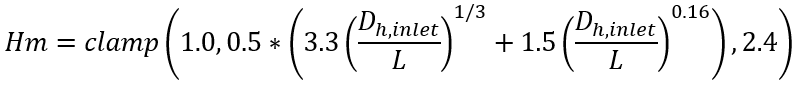

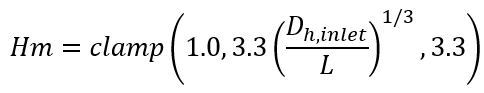

Turbulent Duct Flow Entrance Effects

The following entrance effects correlations compute an HTC multiplier called Hm. HTC

multiplier has limits and must be greater than unity. The Local option resolves heat

transfer correctly for all x locations along the axial length of a pipe. The

Averaged options use total pipe length L as the input. They correctly predict

overall heat transfer, but not local temperature variation.

Abrupt Contraction, Local x

Uniform Bellmouth, Local x

Abrupt Contraction, Averaged L

Uniform Bellmouth, Averaged L

Uniform Blend, Local x

Uniform Blend, Averaged L

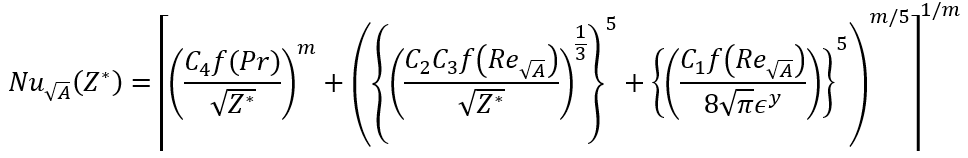

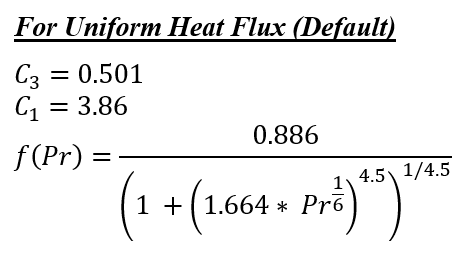

Laminar Duct Flow HTC correlations

The

following Laminar HTC options are available in Flow Simulator. It is worth noting

that Laminar HTCs depend on distance from inlet x, and thus do not need a special

Entrance Effects multiplier.

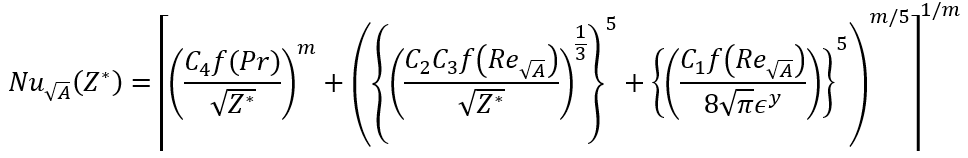

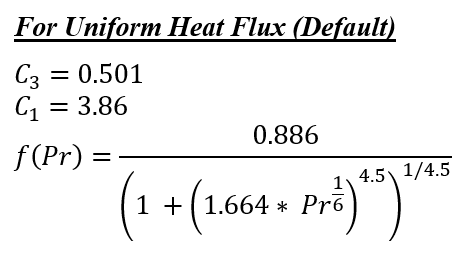

Muzychka-Yovanovich:

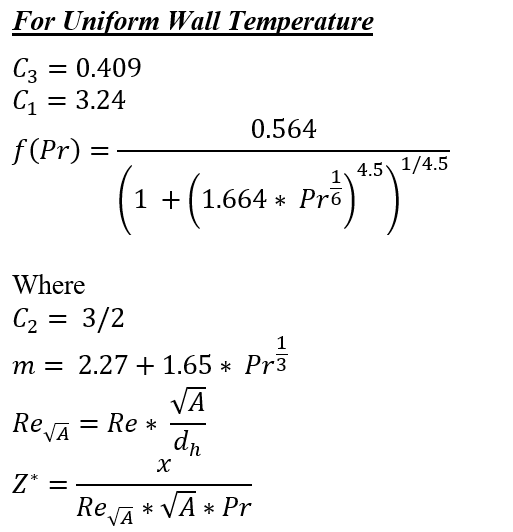

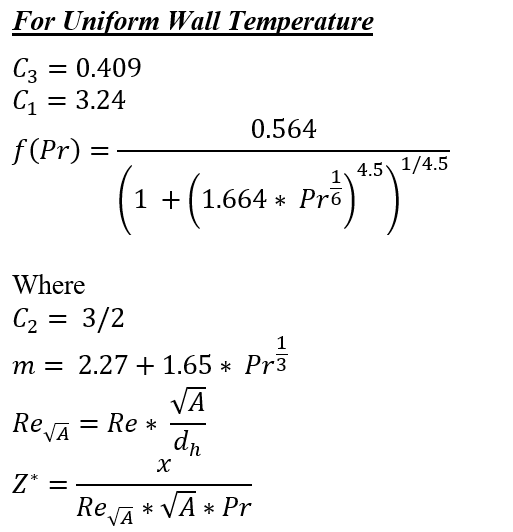

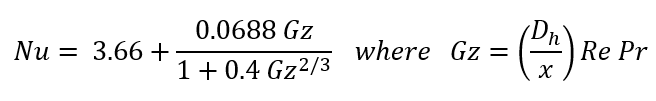

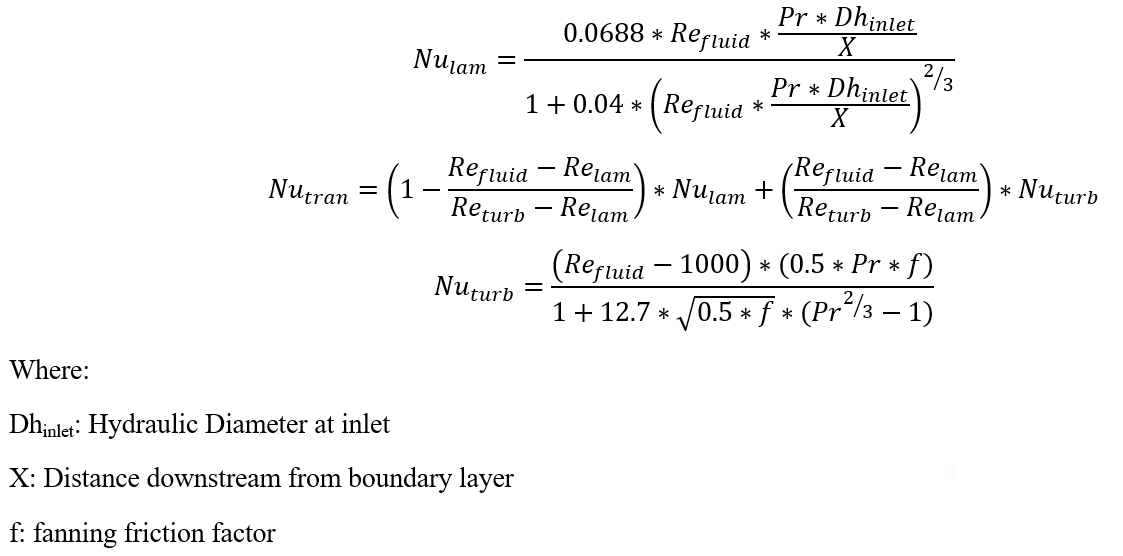

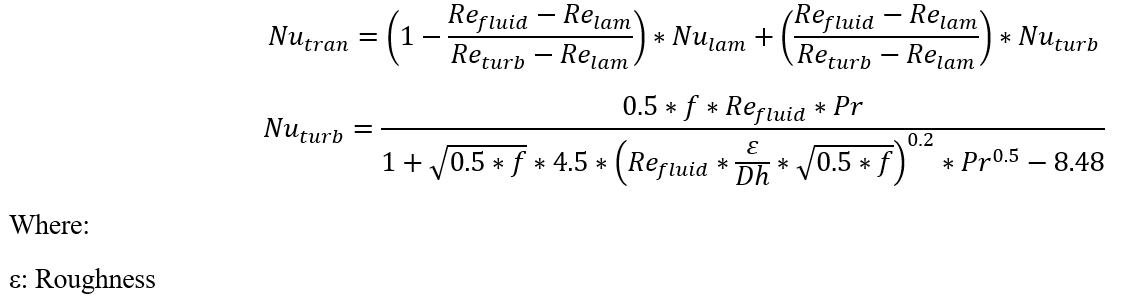

Hausen:

![]()

![]()

![]()

![]()

![]()