Silk Print Between Two pins

Check the existence of silkscreen between two pins of DIP type components.

In the wave-soldering process, silkscreen between two pins is necessary to prevent solder flow from one to another.

The Silk Print Between Two Pins dialog contains the following

sections:

- Target Components Definition

- Component Group Selection: Component selection when selecting from the group list.

- Selection by Pin Pitch: Among the selected component group, target

components will match with the following conditions.

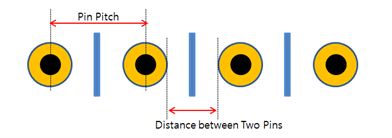

Figure 1.

- Condition: Select And or Or condition for the Pin Pitch option that is entered in 2) ~ 4).

- Maximum Pin Pitch (Center to Center): Target components will be the component that has smaller pin pitches.

- Minimum Pin Pitch (Center to Center): Target components will be the component that has larger pin pitches.

- Maximum Distance between Pin Edges: Target components will be the component that has a smaller distance between two pin edges.

- Minimum Distance between Pin Edges: Target components will be the component that has a larger distance between two pin edges.

- Silkscreen Layer Definition

- Silkscreen Layer Selection: Select the silkscreen layer from the layer list.

- Target Layer Definition: Select the layer where the silkscreen should be

placed.

- Component Placed Layer: If the component is placed on top, silkscreen should be placed on the silkscreen top layer. Vice versa is also valid.

- Opposite Side of Component Placed Layer: If the component is placed on top, silkscreen should be placed on bottom layer and vice versa.

- Both: Top and bottom silkscreen will be passed.

- Option

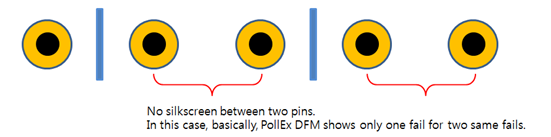

- Display Fail Result for All Pins. (Default: Display representative

One Fail for a Component): PollEx DFM shows

a representative a fail result for the components fail. Using this

option, keep all fail occurring points in the result.

Figure 2.

- Display Fail Result for All Pins. (Default: Display representative

One Fail for a Component): PollEx DFM shows

a representative a fail result for the components fail. Using this

option, keep all fail occurring points in the result.