Make Board Paneling Tutorial

Make Board Paneling is a function to modify the data designed with a single sub board into an array type to use manufacturing related features such as Metal Mask Manager, Mounting Emulator, Block JIG Generator, Router-Machine JIG Generator, and so on.

Make Board Paneling using PDBB

- Launch PollEx PCB.

- From the menu bar, click File > Open and open the PollEx_PCB_Sample_r<revision number>.pdbb file from C:\ProgramData\altair\PollEx\<version>\Examples.

-

From the menu bar, click Manufacture > Make Board Paneling.

The design file is saved as a *.pdbb file. The Make Board Paneling dialog opens.

-

Create array number one.

- In the Make Board Paneling dialog, enable the Route checkbox.

- Enable the Board Figure checkbox.

- Enable the Board Outline checkbox.

- Under Placement, select Move To and enter 0 for both X and Y.

- Click Add Board.

Array number one is registered in the array list. -

Create array number two.

- Enable the Mirror checkbox.

- Select Y Mirror.

- Under Placement, select Move To and enter 137.2 for X and 0 for Y.

- Click Add Board.

Array number two is registered in the array list. -

Create array number three.

- Enable the Mirror checkbox.

- Select X Mirror.

- Under Placement, select Move To and enter 0 for X and 140.8 for Y.

- Click Add Board.

Array number three is registered in the array list. -

Create array number four.

- Disable the Mirror checkbox.

- Enable the Rotation checkbox.

- For Rotation Angle, enter 180.

- Under Placement, select Move To and enter 137.2 for X and 140.8 for Y.

-

Click Add Board.

Array number three is registered in the array list.

-

Click Apply.

The original data is copied and arranged as registered in the Array list.

Figure 1.

Figure 2.

Figure 3. -

Create Panel outline.

In the Define Panel outline section, you can define the Panel Board outline.

Figure 4.- For Start Location, enter -7 for both X and Y.

- For End Location, enter 144.2 for X and 147.8 for Y.

- For Line Width, enter 0.1.

-

Click Apply.

The panel board outline is drawn.

- Click Close to close the Make Board Paneling dialog.

Make Board Paneling using Gerber Data

- Launch PollEx PCB.

- From the menu bar, click File > Open and open the PollEx_PCB_Sample_r<revision number>.pdbb file from C:\ProgramData\altair\PollEx\<version>\Examples.

-

Import Gerber data.

When the Metal Mask Gerber of the panel board is prepared, the sub-boards can be automatically calculated by selecting the component pad of the design data and the pad object of the Gerber data.

-

From the menu bar, click File > Import > Gerber (RS-274D/RS-274X).

The Import from Gerber (RS-274D/RS-274X) dialog opens.

-

In the Import from Gerber (RS-274D/RS-274X)

dialog, click

.

.

- Select all Top-Metal files from C:\ProgramData\altair\PollEx\<version>\Examples\MFG\Data\MetalMaskGerber.

-

From the tool bar, click

to

disable routing data.

to

disable routing data.

-

From the menu bar, click File > Import > Gerber (RS-274D/RS-274X).

-

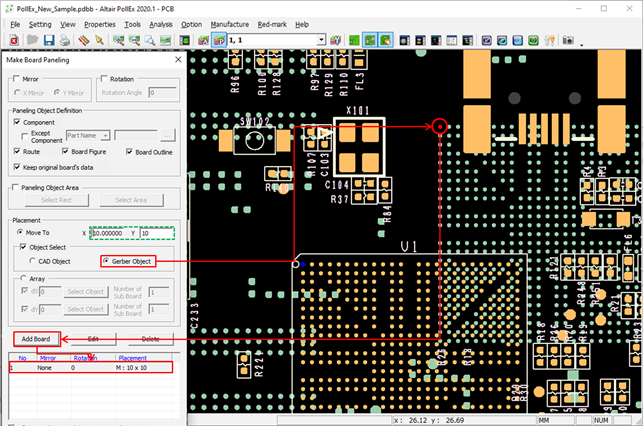

From the menu bar, click Manufacture > Make Board Paneling.

The Make Board Paneling dialog opens. The design file is saved as a *.pdbb file. If the file is not saved, the Make Board Paneling cannot be used.

Figure 5. -

Create Array List by selecting CAD and Gerber data.

- In the Paneling Object Definition section of the Make Board Paneling dialog, enable the following checkboxes: Route, Board Figure, and Board Outline.

- In the Placement section, enable the Object Select checkbox and select CAD Object.

- Select the Pad to be used as the reference from the CAD data.

Figure 6. -

Select pad based on Gerber data.

- In the Placement section, select Gerber Object.

-

Select the Pad to be used as the reference from the Gerber data.

X and Y distance between two selected objects from CAD and Gerber data is automatically calculated.

-

Click Add Board to enter the first array

information in the Array list.

Figure 7. - Move the main screen to the right-side of the board.

-

Select the Pad to create the second array board.

X and Y distance between the two selected objects from CAD and Gerber data is automatically calculated.

-

Click Add Board to enter the second array

information in the Array list.

Figure 8. -

Click Apply.

The original data is copied and arranged as registered in the Array list.

Figure 9.

-

Create Panel outline.

Use the Get Panel Outline from Gerber option to define the Panel Outline.

-

Click Get Panel Outline from Gerber.

Figure 10.The Extract Board Outline dialog opens. - In the Extract Board Outline dialog, select Replace.

- Click and drag to select a line to be defined as the Board Outline.

-

Enable the Certain Width checkbox and enter

0.2.

Figure 11. -

Click ALL.

All lines with the same width as the previously selected line are automatically selected and displayed in purple in the Gerber data.

Figure 12. -

Click Apply in the

Extract Board Outline dialog.

Selected lines from the Gerber data are changed to the Panel Outline.

-

Click Close in the Make Board

Paneling dialog.

Figure 13.

-

Click Get Panel Outline from Gerber.