Component

- Reflow Process: In the Reflow Process, when an SMD component is present on

the surface where the soldering pallet is generated, a rule for creating a

support supporting the soldering pallet is entered in the region where the

component does not exist.

- Target Component: SMD component placed in Soldering Pallet.

- Clearance from Pad to Pallet Area: Distance between Pad and Pallet Area of SMD parts.

- Supporter Rule: separation distance to create support.

- Clearance from Component COC: The separation distance between the support and the outside of the component.

- Width of Supporter: Thickness of support.

- Clearance between Supporters: Distance between support groups. If the supports cannot be generated continuously, a certain separation distance between the support groups must be maintained.

- Pallet to Component: Check the separation distance between the soldering

pallet and the solder mask of the SMD/DIP/Board figure. Low Height Component

can set different setting standard of separation distance from Soldering

Pallet.

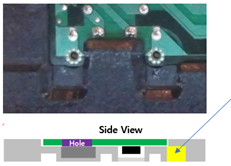

Figure 3. - Pallet Bottom: It is possible to designate a stepped area that occurs around

parts such as corners and screws of soldering pallets.

Figure 4. Data Generated on the Bottom Side of the Soldering Pallet

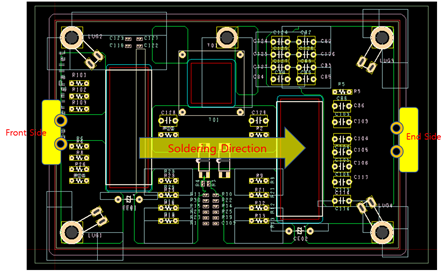

Figure 5. Front Side, End Side According to the Direction of Soldering Direction- Searching Target Component by Pin Pitch: Enter the value to generate a step on the front side and end side of the soldering direction of the PCB for parts with the same pin pitch of the component.

- Pin Pitch: Expands the area by the value of Front/End Side for the parts with the same pin pitch.

- Front Side Clearance: For parts existing at the beginning of the soldering direction, the value to expand the area.

- End Side Clearance: For parts present at the end of the soldering direction, the value to expand the area.

- Horizontal and Vertical are based on Soldering Direction, and the data is generated by expanding the area to Horizontal and Vertical based on the COC area of the part specified in Target Component Selection.

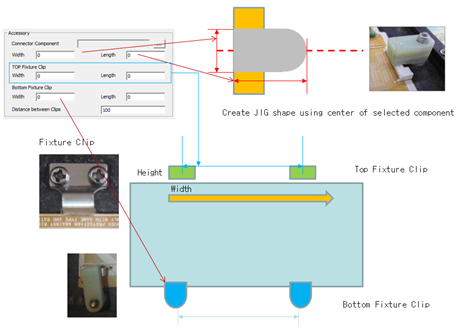

- Accessory: When Soldering Pallet is installed, data

for creating the placement area of devices for fixing the PCB is entered. It

does not participate in the process of creating the soldering pallet, but

for the convenience of the user, it creates data of the size entered in the

designated part.

Figure 6. Accessory Explanation